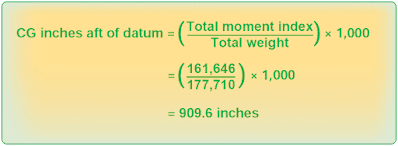

A loading schedule is used to document compliance with the certificated weight and balance limitations contained in the manufacturer’s AFM and weight and balance manual. The basic operating weight (BOW) and the operating index are entered into a loading schedule like the one in Figure 1, and the variables for a specific flight are entered as appropriate to determine the loaded weight and CG.

|

| Figure 1. Loading schedule |

Use the data in this example:

Basic operating weight: 105,500 lb

Basic operating index (total moment/1,000): 98,837.0

MAC: 180.9 in

LEMAC: 860.5

|

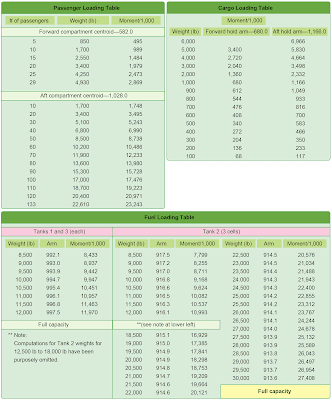

| Figure 2. Loading schedule for determining weight and CG |

The airplane is loaded in this way:

Passengers (nominal weight—170 pounds each)

Forward compartment: 18

Aft compartment: 95

Cargo

Forward hold: 1,500 lb

Aft hold: 2,500 lb

Fuel

Tanks 1 and 3: 10,500 lb each

Tank 2: 28,000 lb