Requirements

Regulations do not require periodic weighing of privately owned and operated aircraft. Such aircraft are usually weighed when originally certificated or after major alterations that can affect the weight and balance. The primary purpose of aircraft weight and balance control is safety. Manufacturers conduct extensive flight tests to establish loading limits for their aircraft because limit information is critical for safe flight.A secondary purpose is to aid efficiency during flight. Overloading of the aircraft is not the only concern; the distribution of the weight is important also. The aircraft has CG limits, and any loading that places the CG outside the established limits seriously impairs controllability of the aircraft.

Weight and balance is of such vital importance that each Federal Aviation Administration (FAA) certificated mechanic or repairman maintaining an aircraft must be fully aware of his or her responsibility to provide the pilot with current and accurate information for the actual weight of the aircraft and the location of the CG. The pilot in command (PIC) is responsible for knowing the weight of the load, CG, maximum allowable weight, and CG limits of the aircraft. The weight and balance report must include an equipment list showing weights and moment arms of all required and optional items of equipment included in the certificate empty weight.

Weight and balance records used in accounting for and correcting the CG location are reliable for only limited periods of time. For this reason, periodic aircraft weighing is desirable. An aircraft should be reweighed and a new weight and balance record should be started after the aircraft has undergone extensive repair or major alteration, when the pilot reports unsatisfactory flight characteristics (e.g., nose or tail heaviness), and when recorded weight and balance data are suspected to be in error.

Repairs and alterations are major sources of weight change. The airframe and powerplant (A&P) FAA-certificated mechanic or repairman who is responsible for making any repair or alteration must:

- Establish by computation that the authorized weight and CG limits as shown in the type certificate data sheet (TCDS) and aircraft specifications are not exceeded, and

- Record the new empty weight center of gravity (EWCG) data in the current approved aircraft flight manual or issued operating limitations.

When an aircraft has undergone extensive repair or major alteration, it should be reweighed and a new weight and balance record started. The A&P FAA-certificated mechanic or repairman responsible for the work must provide the pilot with current and accurate aircraft weight information and location of the EWCG.

Equipment for Weighing

Weighing aircraft with accurately calibrated scales is the only sure method of obtaining an accurate empty weight and CG location. The two basic types of scales used to weigh aircraft are platform and load cell.

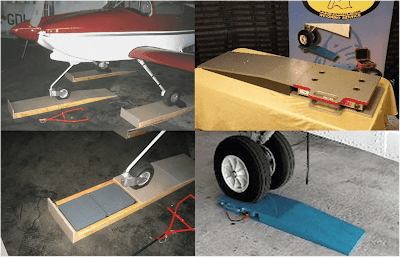

Platform scales [Figure 1] or ramp wheel scales [Figure 2] (usually a form or modified version of the platform scale) are low profile, easy to handle, safe, and reliable. Tow or push the aircraft wheels or skids onto the scale pad at ground level. With one scale per wheel, each device should be capable of measuring up to at least 60,000 pounds since the weight on each wheel rarely exceeds this figure.

|

| Figure 1. Platform scales |

|

| Figure 2. Ramp scales |

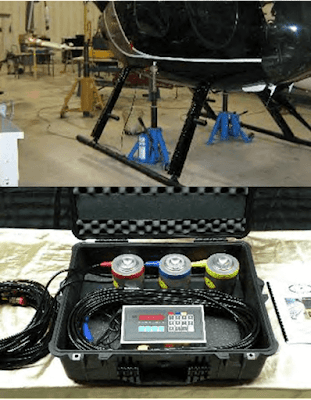

Load cell scales [Figure 3] are also a reliable means to weigh aircraft and are typically cheaper than the platform type. Using load cell scales allows for the aircraft to be set up and weighed in its level flight attitude. With this method, the aircraft is placed on jacks with electronic load cells placed between the jack and the jack pad on the aircraft. The aircraft is raised on the jacks until the wheels or skids are off the floor and the aircraft is in a level flight attitude. The weight measured by each load cell is indicated on the control panel. Jacking an aircraft off the ground from all load points can be an inconvenience, as well as a safety risk, which some operators would rather avoid by opting for more expensive—but simpler to use—platform equipment. In addition, weighing with platform scales typically takes only one-third of the time needed to weigh with load cells.

|

| Figure 3. Load cell scales |

All scales for aviation use, manual or electronic, must be protected when stored or shipped, and they must be checked periodically for accuracy. The maximum recognized period between calibration checks is 12 months; however, this period may be reduced by an airworthiness authority dependent on the conditions of use. Scales in daily use may require a shorter interval and/or testing to determine the continued accuracy of the unit. Scales should be returned to the manufacturer for proper calibration and testing.