In general, weight procedures may vary with the aircraft and types of weight equipment employed. The weighing procedure contained in the manufacturer’s maintenance manual should be followed for each particular aircraft. The major considerations in preparing an aircraft for weighing are described in the following paragraphs.

Scale Preparation

Mechanical and electronic scales shall be inspected prior to use and set to zero. This is done by adding and removing a weight, then rechecking for zero. This process should be repeated until a steady zero setting is obtained. The scales should be located in the same environment in which they are to be used and allowed to come up to temperature at least 2 hours prior to use. Scales should not be used in temperature extremes below 40 °F or above 100 °F unless the scale is specifically designed for use in those temperatures. Electronic scales are very sensitive and, if subjected to freezing temperatures, the liquid displays may be damaged beyond use.

Weigh Clean Aircraft Inside Hangar

The aircraft should be weighed inside a hangar where wind cannot blow over the surface and cause fluctuating or false scale readings. The aircraft should be clean inside and out, with special attention paid to the bilge area to ensure that no water or debris is trapped there. The outside of the aircraft should be as free as possible of all mud and dirt.

Equipment List

All of the required equipment must be properly installed, and there should be no equipment installed that is not included in the equipment list. If such equipment is installed, the weight and balance record must be corrected to indicate it.

Ballast

All required permanent ballasts must be properly secured in place. All temporary ballasts must be removed.

Standard Weights

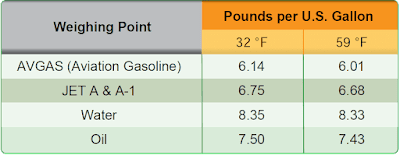

Standard weights are established weights for numerous items involved in weight and balance computations. These weights should not be used if actual weights are available. Some of the standard weights are listed in Figure.

|

| Standard fuels and weights with temperatures of 32 °F and 59 °F |

Note the difference in weight as temperatures change. Although this change is a very small amount per gallon, it could end up in a significant total weight gain when dealing with large quantities of fluids, such as those found in commercial aircraft.

Draining the Fuel

Drain fuel from the tanks in the manner specified by the aircraft manufacturer. If there are no specific instructions, drain the fuel until the fuel quantity gauges read empty when the aircraft is in level-flight attitude. Any fuel remaining in the system is considered residual or unusable fuel and is part of the aircraft empty weight.

The amount of residual fuel and its arm are normally found in Note 1 in the section of the Type Certificate Data Sheets (TCDS), “Data pertaining to all Models.” For additional fuel capacity information, see Weight and Balance Theory section.

If it is not feasible to drain the fuel, the tanks can be topped off to be sure of the quantity they contain and the aircraft weighed with full fuel. After weighing is complete, the weight of the fuel and its moment are subtracted from those of the aircraft as weighed. To correct the empty weight for the residual fuel, add its weight and moment.

When computing the weight of the fuel (e.g., a tank full of jet fuel), measure its specific gravity (sg) with a hydrometer and multiply it by 8.345 (the nominal weight of 1 gallon of pure water whose sg is 1.0). If the ambient temperature is high and the jet fuel in the tank is hot enough for its specific gravity to reach 0.81 rather than its nominal sg of 0.82, the fuel actually weighs 6.76 pounds per gallon rather than its normal weight of 6.84 pounds per gallon.

Oil

The empty weight for aircraft certificated under the Civilian Air Regulations (CAR) part 3 does not include the engine lubricating oil. The oil must either be drained before the aircraft is weighed, or its weight must be subtracted from the scale readings to determine the empty weight. To weigh an aircraft that does not include the engine lubricating oil as part of the empty weight, place it in level flight attitude, then open the drain valves and allow the oil to drain out. Any remaining is undrainable oil and is part of the empty weight. Aircraft certificated under Title 14 of the Code of Federal Regulations (14 CFR) parts 23 and 25 include full oil as part of the empty weight. If it is impractical to drain the oil, the reservoir can be filled to the specified level and the weight of the oil computed at 7.5 pounds per gallon. Then, its weight and moment are subtracted from the weight and moment of the aircraft as weighed. The amount and arm of the undrainable oil are found in Note 1 of the TCDS, and this must be added to the empty weight.

Other Fluids

The hydraulic fluid reservoir and all other reservoirs containing fluids required for normal operation of the aircraft should be full. Fluids not considered to be part of the empty weight of the aircraft are potable (drinkable) water, lavatory precharge water, and water for injection into the engines.

Configuration of the Aircraft

Consult the aircraft service manual regarding position of the landing gear shock struts and the control surfaces for weighing. When weighing a helicopter, the main rotor must be in its correct position.

Jacking the Aircraft

Aircraft are often weighed by rolling them onto ramps in which load cells are embedded. This eliminates the problems associated with jacking the aircraft off the ground. However, many aircraft are weighed by jacking the aircraft up and then lowering them onto scales or load cells.

Extra care must be used when raising an aircraft on jacks for weighing. If the aircraft has spring steel landing gear and it is jacked at the wheel, the landing gear will slide inward as the weight is taken off of the tire, and care must be taken to prevent the jack from tipping over.

For some aircraft, stress panels or plates must be installed before the aircraft is raised with wing jacks to distribute the weight over the jack pad. Be sure to follow the recommendations of the aircraft manufacturer in detail anytime an aircraft is jacked. When using two wing jacks, take special care to raise them simultaneously, keeping the aircraft so it does not slip off the jacks. As the jacks are raised, keep the safety collars screwed down against the jack cylinder to prevent the aircraft from tilting if one of the jacks should lose hydraulic pressure.

Leveling the Aircraft

When an aircraft is weighed, it must be in its level flight attitude so that all of the components are at their correct distance from the datum. This attitude is determined by information in the TCDS. Some aircraft require a plumb line to be dropped from a specified location so that the point of the weight (the bob) hangs directly above an identifiable point. Others specify that a spirit level be placed across two leveling lugs, often special screws on the outside of the fuselage. Other aircraft call for a spirit level to be placed on the upper door sill.

Lateral level is not specified for all light aircraft, but provisions are normally made on helicopters for determining both longitudinal and lateral level. This may be done by built-in leveling indicators, or by a plumb bob that shows the conditions of both longitudinal and lateral level.

The actual adjustments to level the aircraft using load cells are made with the jacks. When weighing from the wheels, leveling is normally done by adjusting the air pressure in the nosewheel shock strut.

Safety Considerations

Special precautions must be taken when raising an aircraft on jacks.

- Stress plates must be installed under the jack pads if the manufacturer specifies them

- If anyone is required to be in the aircraft while it is being jacked, there must be no movement.

- The jacks must be straight under the jack pads before beginning to raise the aircraft.

- All jacks must be raised simultaneously and the safety devices are against the jack cylinder to prevent the aircraft tipping if any jack should lose pressure. Not all jacks have screw down collars, some use drop pins or friction locks.