The light-sport aircraft (LSA) concept broadens the access of flight to more people. LSA have been defined as a simple-to-operate, easy-to-fly aircraft; however, “simple-to-operate” and “easy-to-fly” do not negate the need for proper and effective training. This post introduces the light-sport category of airplanes and places emphasis on transition to a light-sport airplane.

Even though light-sport airplane flight may appear simple to an experienced pilot, a transition to a light-sport airplane should include the same methodical training approach as transitioning into any other airplane. A pilot seeking a transition into light-sport airplane flying should follow a systematic, structured light-sport airplane training course under the guidance of a competent instructor with recent experience in the specific training airplane.

Light-Sport Aircraft Background

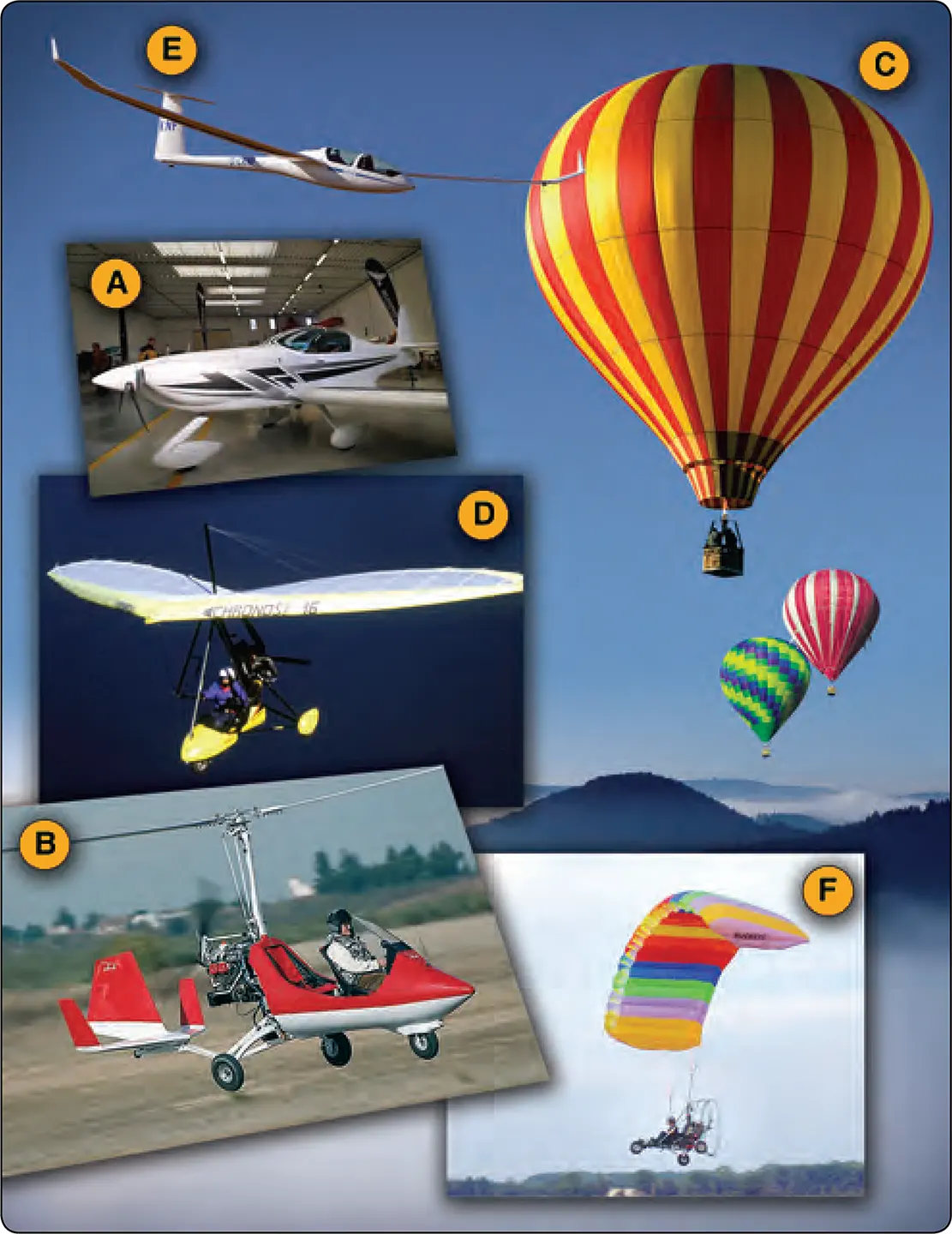

Several groups were instrumental in the development and success of the LSA concept. These included the Federal Aviation Administration (FAA), Light Aircraft Manufacturers Association, American Society for Testing and Materials (ASTM) International, and countless individuals who promoted the concept since the early 1990s. In 2004, the FAA released a rule that created a light-sport classification for airplane, gyroplane, lighter-than-air, weight-shift-control, glider, and powered parachute. [Figure 1]

The primary concept of the LSA is built around a defined set of standards found in 14 CFR part 1, section 1.1:

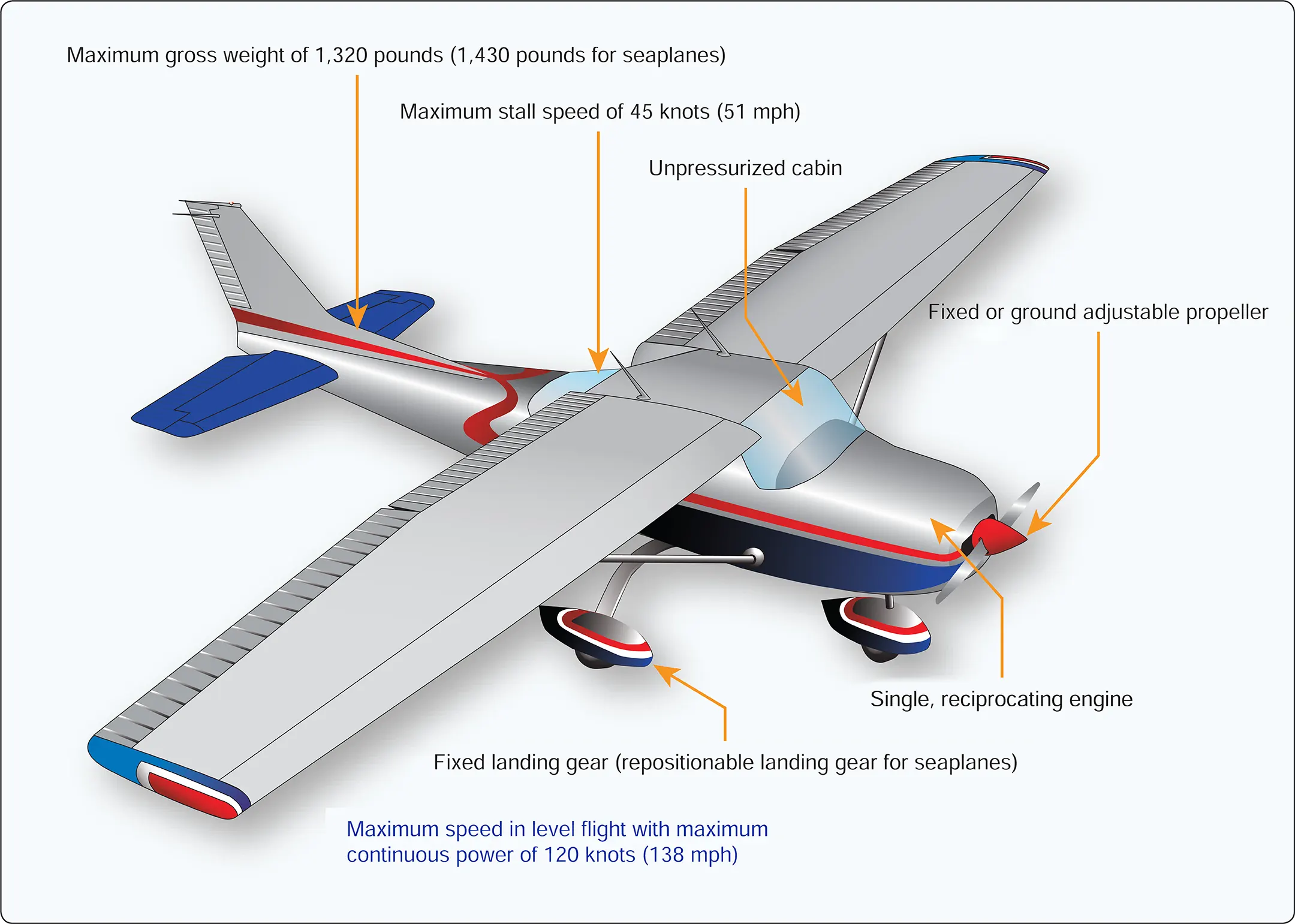

- Powered (if powered) by single reciprocating engine.

- Fixed landing gear (except seaplanes and gliders).

- Fixed pitch or ground adjustable propeller.

- Maximum takeoff weight of 1,320 pounds for landplane, 1,430 for seaplane.

- Maximum of two occupants.

- Non-pressurized cabin.

- Maximum speed in level flight at maximum continuous power of 120 knots calibrated airspeed (CAS).

- Maximum stall speed of 45 knots. [Figure 2]

The LSA category includes standard, special, and experimental designations. Some standard airworthiness certificated aircraft (i.e., a Piper J-2 or J-3) may meet the Title 14 of the Code of Federal Regulation (14 CFR) part 1, section 1 definition of LSA. Type certificated aircraft that continue to meet the section 1.1 definition of LSA may be flown by a pilot who holds a sport pilot certificate with the appropriate endorsement for the aircraft (14 CFR part 61, section 61.315(a)). The sport pilot certificate is discussed later in this post. Aircraft that are specifically manufactured for the LSA market are included in either the Special (S-LSA) or Experimental (E-LSA) designations. An approved S-LSA is manufactured in a ready-to-fly condition and an E-LSA is either a kit or plans-built aircraft based on an approved S-LSA model.

It is important to note that S-LSAs or E-LSAs are not type certificated by the FAA and are not required to meet any airworthiness requirements of 14 CFR part 23. Instead, S-LSAs and E-LSAs are designed and manufactured in accordance with ASTM Committee F-37 Industry Consensus Standards. Therefore, LSA designs are not subjected to the scrutiny, demands, and testing of FAA standard airworthiness certification. Industry Consensus Standards are intended to be less costly and less restrictive than 14 CFR part 23 certification requirements and, as a result, LSA manufacturers have greater latitude with their designs. ASTM Industry Consensus Standards were accepted by the FAA in 2005, which established FAA-accepted industry-developed standards for the design and manufacture of aircraft for the first time.ASTM Industry Consensus Standards for LSA cover the following areas:

- Design and performance

- Required equipment

- Quality assurance

- Production acceptance tests

- Aircraft operating instructions

- Maintenance and inspection procedures

- Identification and recording of major repairs and major alterations

- Continued airworthiness

- Manufacturer’s assembly instructions (E-LSA aircraft)

Using the ASTM Industry Consensus Standards, an LSA manufacturer can design and manufacture their aircraft and assess its compliance to the consensus standards. The manufacturer then, through evaluation services offered by a designated airworthiness representative, completes the process by submitting the required paperwork to the FAA. Upon approval, an LSA manufacturer is permitted to sell ready-to-fly S-LSA aircraft.

Light-Sport Airplane Synopsis

- The airplane must meet the weight, speed, and other criteria listed in 14 CFR part 1, section 1 that define an LSA.

- Airplanes under the S-LSA certification commonly find use in sport and recreation, flight training, and aircraft rental.

- E-LSA-certified airplanes may be used for sport and recreation and flight instruction for the owner of the airplane. However, E-LSA certification is not the same as Experimental Amateur-Built aircraft certification. E-LSA certification is based on an approved S-LSA airplane.

- FAA policy allows sport pilots with an airplane rating to fly certain airplanes (i.e., a Piper J-2 or J-3) that continue to meet the 14 CFR part 1, section 1 LSA definition even though the airplane was originally issued a standard airworthiness type certificate.

- No person may operate the aircraft unless it has been registered by its owner, if eligible for registration, per 14 CFR part 47, section 47.3(b).

- United States or foreign manufacturers can be authorized.

- FAA policy allows holders of a sport pilot certificate or higher level pilot certificate (recreational, private, commercial, or ATP) to pilot sport aircraft.

- LSAs may be operated by VFR at night if the aircraft is equipped with the instruments and equipment specified in 14 CFR part 91, section 91.205(c), and if night operations are allowed by the airplane’s operating limitations. However, sport pilots may not fly at night (14 CFR 61.315(c)(5)).

- LSAs may be operated between sunset and sunrise by a recreational pilot as the sole occupant of the aircraft, in accordance with 14 CFR part 61, section 61.101(i)(3) for the purpose of obtaining additional certificates or ratings and while under the supervision of an authorized instructor and provided the flight or surface visibility is at least 5 statute miles.

Sport Pilot Certificate

In addition to the LSA rules, the FAA created a new sport pilot certificate in 2004 that lowered the minimum training time requirements, in comparison to other pilot certificates, for newly certificated pilots wishing to exercise privileges only in LSA aircraft. Pilots who hold recreational, private, commercial, or airline transport pilot certificates may pilot light-sport airplanes provided they possess the appropriate category/class rating and a U.S. driver’s license or medical certificate that meets the requirements for the aircraft displayed in the 14 CFR part 61, section 61.303 table. For example, a commercial pilot rated in airplane multiengine land and rotorcraft gyroplane is qualified to fly a light-sport gyroplane as pilot in command (PIC) if also holding a medical certificate or a U.S. driver’s license. However, that pilot is not qualified to act as PIC of a light-sport airplane (sport airplanes are single-engine) without supervision from an authorized instructor.

Pilots holding higher level certificates with the appropriate category and class ratings may fly LSAs as long as the pilot holds a valid U.S. driver’s license as evidence of medical eligibility. However, if the pilot’s most recent medical certificate was denied, revoked, suspended, or withdrawn, a U.S. driver’s license is not sufficient. The pilot would then need to hold a valid FAA medical certificate to fly an LSA.

Transition Training Considerations

Flight Schools

The LSA category has created new business opportunities due to low fuel usage, reliability, and low maintenance costs. Many owners and operators of flight schools use S-LSAs for flight instruction and rental.

When considering a transition to LSA, a pilot should look for a flight school that has experience in LSA instruction and can provide quality instruction. Personally touring a school and soliciting feedback from other pilots that have transitioned into LSAs may help find an appropriate school. Some questions to be asked include the following:

- How many pilots has the flight school transitioned into LSAs and how many LSAs are available for instruction?

- What are the flight school’s rental, insurance, and safety policies?

- How is maintenance accomplished and by whom?

- How are records maintained and how is scheduling accomplished?

Flight Instructors

The flight instructor is an important link in a successful LSA transition. A transitioning pilot should choose a flight instructor that has verifiable experience in LSA instruction. The Sport Pilot rule allows for a Sport Pilot flight instructor certificate, the flight instructor-S. 14 CFR part 61, section 61.413 limits a flight instructor-S to instruction in LSAs—a flight instructor-S cannot give instruction in a non-LSA airplane (e.g., a Cessna 150). While FAA policy allows a flight instructor certificated as a flight instructor-A to give instruction in both a light-sport airplane and a non-light-sport airplane, a flight instructor-S with teaching experience in LSA might provide better instruction than a flight instructor-A who has minimal teaching experience in light-sport airplanes.

A transitioning LSA pilot should have an opportunity to review the curriculum, syllabus, lesson plans, as well as the process for tracking progress through the training program. Depending on the transitioning pilot’s experience, currency, and type of airplane typically flown, the flight instructor should make appropriate adjustments to any LSA training curriculum. A suggested LSA transition training outline is presented:

- CFR review as pertaining to LSAs and sport pilots

- Pilot’s Operating Handbook (POH) review

- LSA maintenance

- LSA weather considerations

- Wake turbulence avoidance

- Performance and limitations

- Operation of systems

- Ground operations

- Preflight inspection

- Before takeoff check

- Normal and crosswind takeoff and climb

- Normal and crosswind approach and landing

- Soft-field takeoff, climb, approach, and landing

- Short-field takeoff, climb, approach, and landing

- Go-around/rejected landing

- Steep turns

- Stalls and spin awareness

- Emergency approach and landing

- Systems and equipment malfunctions

- After landing, parking, and securing

LSA Maintenance

LSAs should be treated with the same level of care as any standard airworthiness certificated airplane. However, S-LSAs have greater latitude pertaining to who may conduct maintenance as compared to standard airworthiness certificated airplanes. S-LSAs may be maintained and inspected by:

- An LSA Repairman with a Maintenance rating; or,

- An FAA-certificated Airframe and Powerplant Mechanic (A&P); or,

- As specified by the aircraft manufacturer; or

- As permitted, owners performing limited maintenance on their S-LSA.

The airplane maintenance manual includes the specific information for repair and maintenance on inspections, repair, and authorization for repairs and maintenance. Most often, S-LSA inspections can be signed off by an FAA-certificated A&P or LSA repairman with a Maintenance rating rather than an A&P with Inspection Authorization (IA); however, the aircraft maintenance manual provides the procedures to follow. The FAA does not issue Airworthiness Directives (ADs) for S-LSAs or E-LSAs. If an FAA-certified component is installed on an LSA, the FAA issues any pertaining ADs for that specific component. Manufacturer safety directives are not distributed by the FAA. S-LSA owners should comply with:

- Safety directives (alerts, bulletins, and notifications) issued by the LSA manufacturer

- ADs if any FAA-certificated components are installed

- Safety alerts (immediate action)

- Service bulletins (recommending future action)

- Safety notifications (informational)

S-LSA compliance with maintenance requirements provides greater latitude for owners and operators of these airplanes. Because of the options in complying with the maintenance requirements, pilots who are transitioning to LSAs should understand how maintenance is accomplished; who is providing the maintenance services; and verify that all compliance requirements have been met.

Airframe and Systems

Construction

LSAs may be constructed using wood, tube and fabric, metal, composite, or any combination of materials. In general, the manufacturer selects materials and design to keep the airplane lightweight while maintaining the structural requirements. Composite LSAs tend to be sleek and modern looking with clean lines as molding of the various components allows designers great flexibility in shaping the airframe. Other LSAs are authentic-looking renditions of early aviation airplanes with fabric covering a framework of steel tubes. Of course, LSAs may be anything in between using both metal and composite construction. [Figure 3]

A pilot transitioning into LSA should understand the types of construction and the typical concerns for each type of construction:

- Steel tube and fabric—while the techniques of steel tube and fabric construction hails back to the early days of aviation, this construction method has proven to be lightweight, strong, and inexpensive to build and maintain. Advances in fabric technology continue to make this method of covering airframes an excellent choice. Fabric can be limited in its life span if not properly maintained. Fabric should be free from tears, well-painted with little to no fading, and should easily spring back when lightly pressed.

- Aluminum—an aluminum-fabricated airplane has been a favorite choice for decades. Pilots should be quite familiar with this type of construction. Generally, airframes tend to be lightly rounded structures dotted with rivets and fasteners. This construction is easily inspected due to the widespread experience with aluminum structures. Any corrosion, working rivets, dents, and cracks should be identified during a pilot’s preflight inspection.

- Composite—a composite airplane is principally made from structural epoxies and cloth-like fabrics, such as bi-directional and uni-directional fiberglass cloths, and specialty cloths like carbon fiber. Airframe components, such as wing and fuselage halves, are made in molds that result in a sculpted, mirror-like finish. Generally, composite construction has few fasteners, such as protruding rivets and bolts. Pilots should become acquainted with inspection concerns such as looking for hair-line cracks and delamination.

Engines

LSAs use a variety of engines that range from FAA-certificated to non-FAA-certificated. Engine technology varies significantly from conventional air-cooled to high revolutions per minute (rpm)/water-cooled designs. [Figure 4] These different technologies present a transitioning pilot new training opportunities and challenges. Since most light-sport airplanes use non-FAA-certificated engines, a transitioning pilot should fully understand the engine controls, procedures, and limitations. In most light-sport airplanes, engines are water-cooled, 4-cycle, and carbureted. These engines have much higher operating rpm and require a gear-box to reduce propeller rpm to the proper range. Because of the higher engine operating rpm, vibration and noise signatures are quite different in most light-sport airplanes when compared to most standard type certificated designs.

Instrumentation

In addition to advanced airframe and engine technology, LSAs often have advanced flight and engine instrumentation. Installation of electronic flight instrumentation systems (EFIS) provides attitude, airspeed, altimeter, vertical speed, direction, moving map, navigation, terrain awareness, traffic, weather, engine data, etc., all on one or two liquid crystal displays. [Figure 5] EFIS has become a cost-effective replacement for traditional mechanical gyros and instruments. Compared to mechanical instrumentation systems, EFIS requires almost no maintenance. There are tremendous advantages to EFIS systems as long as the pilot is correctly trained in their use. EFIS systems can cause a “heads down” syndrome and loss of situation awareness if the pilot is not trained to quickly and properly configure, access, program, and interpret the information provided. If EFIS is installed, transition training should include instruction in the use of the specific EFIS in the training airplane. In some cases, EFIS manufacturers or third party products are available for the pilot to practice EFIS operations on a personal computer as opposed to learning their functions in flight.

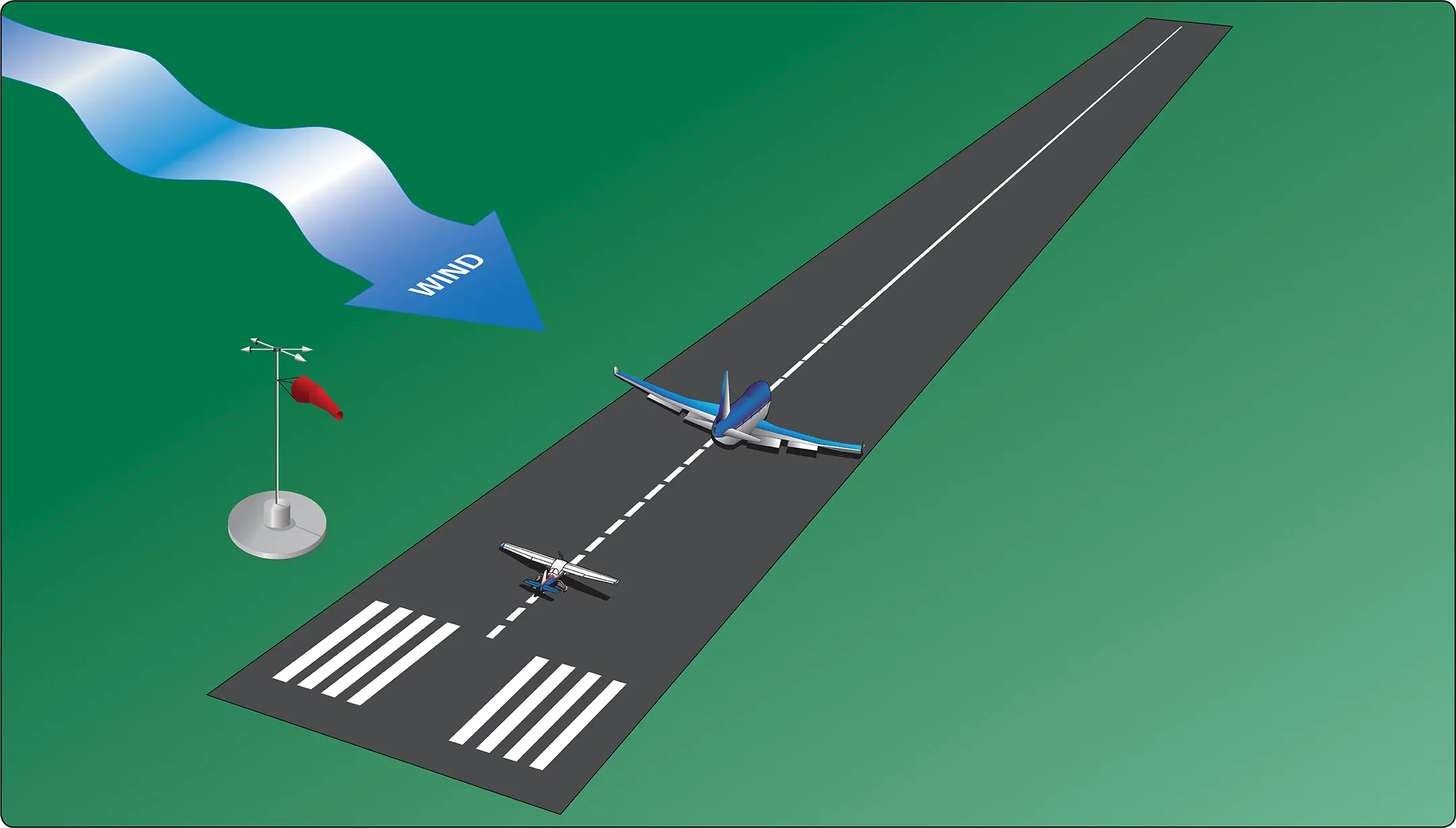

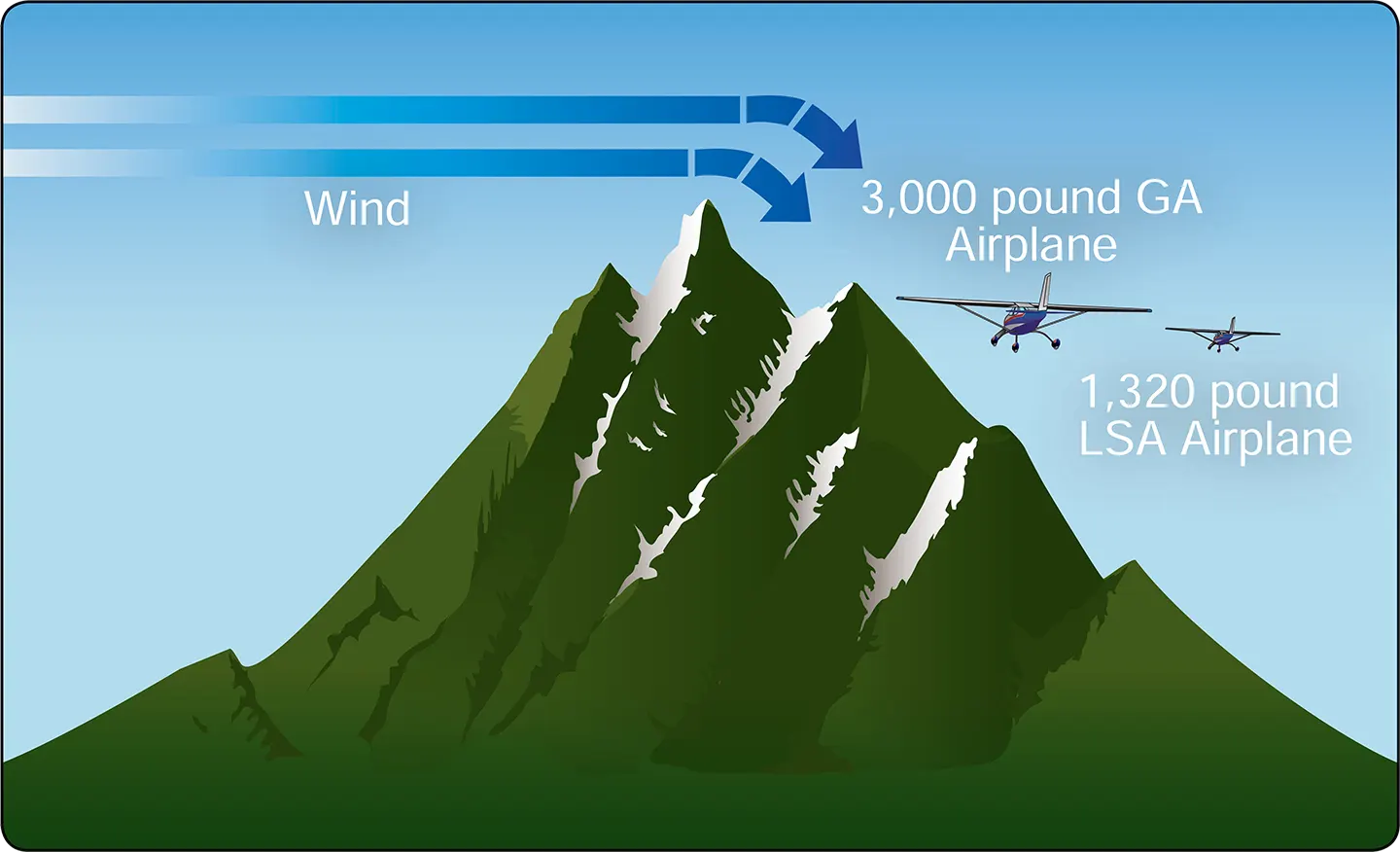

Weather Considerations

Managing weather factors is important for all aircraft but becomes more significant as the weight of the airplane decreases. Smaller, lighter weight airplanes are more easily affected by strong winds (especially crosswinds), turbulence, terrain influences, and other hazardous conditions. [Figures 6 and 7]

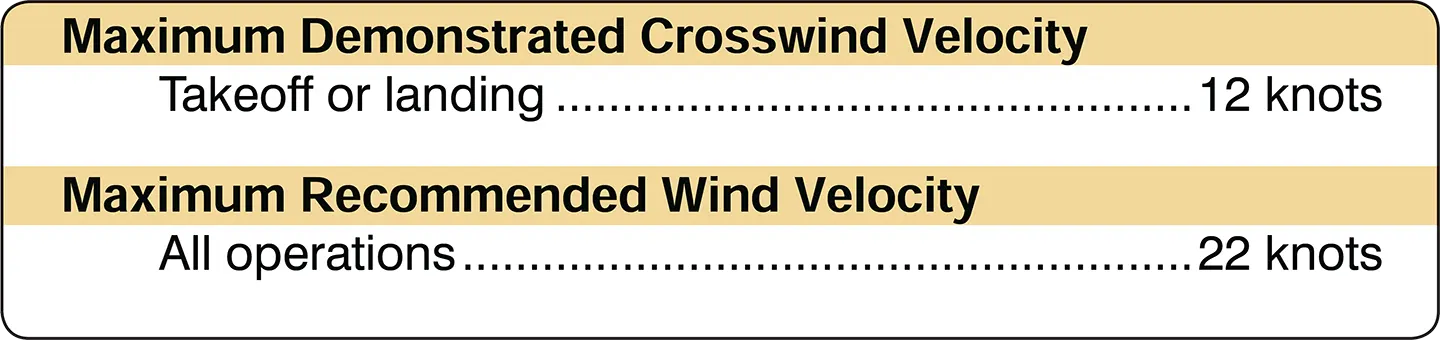

LSA Pilots should carefully consider any hazardous weather and effectively use an appropriate set of personal minimums to mitigate flight risk. Some LSAs have a maximum recommend wind velocity regardless of wind direction. [Figure 8] While this is not a limitation, it would be prudent to heed any factory recommendations.

Due to an LSA’s lighter weight, even greater distances from convective weather should be considered the norm. While low-level winds that enter and exit a thunderstorm should be avoided by all airplanes, operations in the vicinity of convection should not be attempted in lightweight airplanes. Since it is not always possible to fly in clear, calm air, pilots of lighter weight LSAs should carefully manage all weather-related risks. For example, some consideration should be given to flight activity that crosses varying terrain boundaries, such as grass or water to hard surfaces. Differential heating can cause lighter weight airplanes to experience sinking and lifting to a greater degree than heavier airplanes. Careful planning, knowledge, experience, and an understanding of the flying environment assists in mitigating weather-related risks.

Flight Environment

The skills used to fly LSAs resemble those pilots use when flying any airplane, but the techniques may vary. This section outlines areas that are unique to light-sport airplanes. Most skills learned in a standard airworthiness type certificated airplane are transferable to LSAs; however, since LSAs can vary significantly in performance, equipment, systems, and construction, pilots should seek competent flight instruction and refer to the airplane’s POH for detailed and specific information prior to flight.

Preflight

The preflight inspection of any airplane is critical to mitigating flight risks. A pilot transitioning into an LSA should allow adequate time to become familiar with the airplane prior to a first flight. First, the pilot and flight instructor should review the POH and cover the airplane’s limitations, systems, performance, weight and balance, normal procedures, emergency procedures, and handling requirements. [Figure 9]

Inside the Airplane

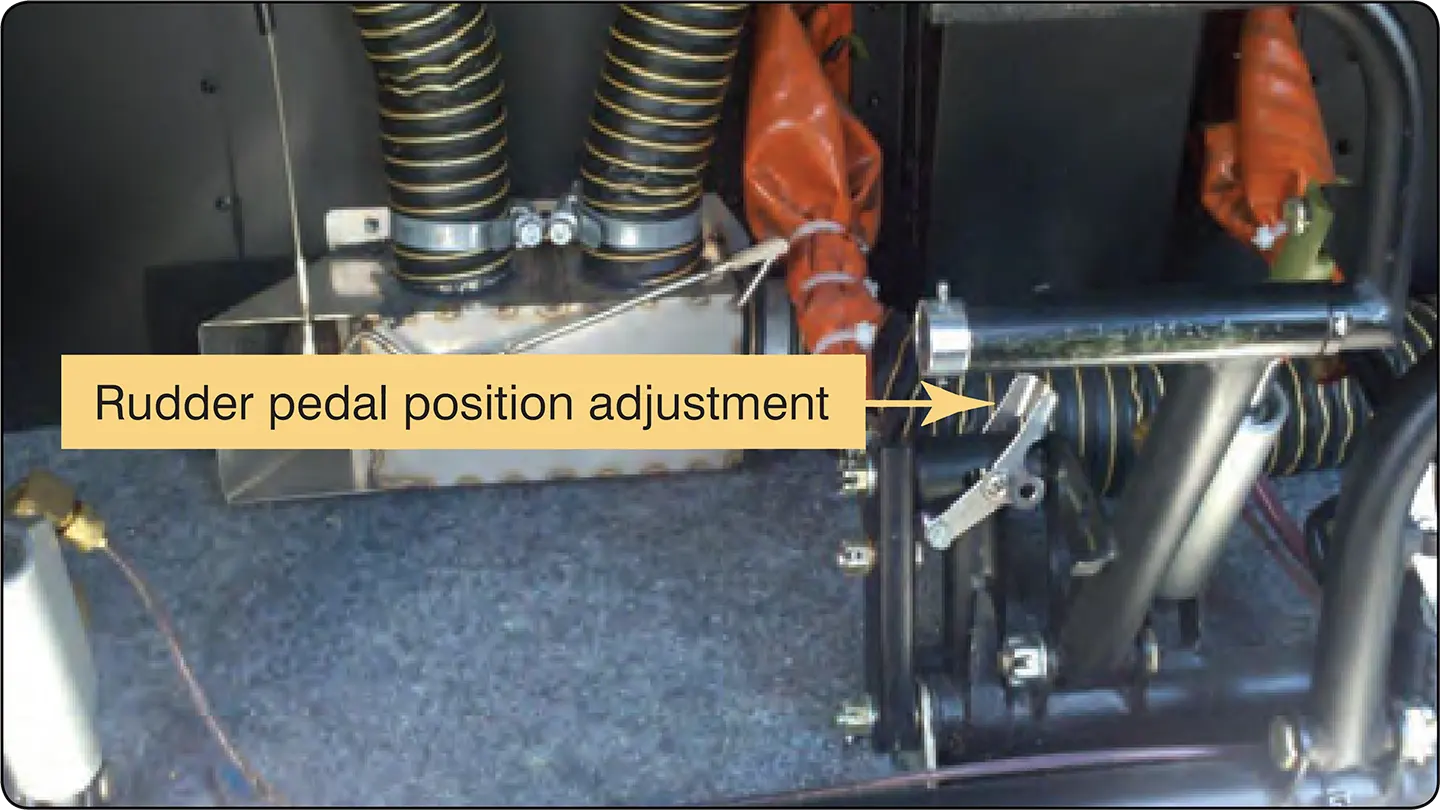

Transitioning pilots find an LSA very familiar when conducting a preflight inspection; however, some preflight differences are worth pointing out. For example, many LSAs do not have adjustable seats but rather adjustable rudder pedals. [Figure 10] Often, LSA seats are in a fixed position. LSA manufacturers have implemented various systems for rudder pedal position adjustment. Some manufacturers use a simple removable pin while others use a knob near the rudder pedals to adjust position. Shorter pilots may find that the adjustment range may not be sufficient, and an appropriate seat cushion may be needed to experience the proper range of rudder pedal movement. In addition, seats in some LSAs are in a semi-reclined position. The first time a pilot sits in a semi-reclining seat, it may seem somewhat unusual. A pilot should take time to get comfortable.

Transitioning pilots should become familiar with the flight and engine controls. These may vary significantly from airplane model to airplane model. Some light-sport airplanes use a conventional control stick while others use a yoke. One manufacturer has combined the two types of controls in what has been termed a “stoke.” While this control may seem unique, it provides a completely natural feel for flight control. [Figure 11] Regardless of the flight controls, the pilot should perform a full range of motion check of the flight controls. This means full forward to full forward left to full aft left to full aft right and then full forward right. Verify that each control surface moves freely and smoothly. On some LSAs, aileron control geometry, in an attempt to minimize adverse yaw, moves ailerons in a highly differential manner; a pilot may see very little “down” aileron when compared to the “up” aileron. Pilots should always verify the direction of control surface movement.

Elevator trim on many LSAs is electrically actuated with no mechanical trim adjustment available. [Figure 12] Depending on the airplane, trim position indication may be displayed on the EFIS, an LED display, or with a mechanical indicator. On electric trim systems, as it is with any airplane, it is important to ensure that the trim position is correctly set prior to takeoff. Because trim positioning/indicting systems vary widely in light-sport airplanes, pilots should fully understand not only how to position the trim, but also how to respond to a trim-run-away condition. Part of the preflight inspection should include actuating the trim switch in both nose-up and nose-down directions, verifying that the trim disconnect (if equipped) is properly functioning, and then properly setting the takeoff trim position.

Depending on the engine manufacturer, the engine controls may be completely familiar to a transitioning pilot (throttle, mixture, and carburetor heat); however, some engines have no mixture control or carburetor heat. Instead, there could be a throttle, a choke control, and carburetor preheater.

Regardless, a pilot should become familiar with the specific engine installed and its operation. A transitioning pilot also needs to become comfortable with the difference between conventional engine control knobs and those found in LSAs. In standard airworthiness airplanes, control knobs are reasonably standardized; however, LSAs may use controls that are much larger or smaller in size.

If the LSA is equipped with an EFIS, the manufacturer’s EFIS Pilot Guide should be available for reference. In addition, the airplane POH likely has specific EFIS preflight procedures that should be completed. These checks are to verify that all internal tests are passed, that no red “Xs” are displayed, and that appropriate annunciators are illuminated. Some systems have a “reversionary” mode where the information from one display can be sent to another display. For example, should the Primary Flight Display (PFD) fail, information can be routed to the Multi-Function Display (MFD). Not all LSA EFIS systems are equipped with a MFD or reversionary capability, so it is important for a transitioning pilot to understand the system and its limitations.

Fuel level in any airplane should be checked both visually and via the fuel level instrument or sight gauges. In LSAs, fuel level quantities can be shown using a variety of systems. Some models may have conventional float activated indictors while others may have the fuel level display on the EFIS with low-fuel alarm capability. It is not uncommon for a light-sport airplane to have advanced EFIS technology for attitude and navigation information, but have a simple sight gauge for fuel level indication. Fuel tank selection can also vary from simple on/off valves to a left/right selector. Fuel starvation remains a leading factor in aircraft accidents, which should be a reminder that when transitioning into a new airplane, time spent understanding the fuel system is time well spent.

A ballistic parachute is a popular safety feature on certain LSAs. [Figure 13] These devices have been shown to be well worth their cost in the unlikely event of a catastrophic failure or some other unsurvivable emergency. This system rockets a parachute into a deployed state such that the parachute slowly lowers the aircraft. The preflight inspections of these systems require a check of the mounts, safety pin and flag, and the activation handle and cable. Because most standard airworthiness type certificated airplanes do not have these systems installed, LSA training should cover the operation and limitations of the system.

Outside the Airplane

Transitioning pilots should feel comfortable and in a familiar setting when preflighting the outside of an LSA. Some unique areas worthy of notation are presented below.

Propellers of LSAs may range from a conventional metal propeller to composite or wood. If a transitioning pilot is principally familiar with metal propellers, time should be spent with the LSA flight instructor covering the type of propeller installed. Many LSA propellers are composite and have a ground adjustable pitch adjustment. There may be more areas to check with these types of propellers. For example, on ground adjustable propellers, ensure that the blades are tight against the hub by snugly twisting the blade at the root to verify that there is no rotation of the blade at the hub.

Many LSAs are equipped with water-cooled engines. LSAs may be tightly cowled, which reduces drag. A liquid-cooled engine minimizes the need for cylinder cooling inlets, which further reduces drag and improves performance. This does present a new system for a transitioning pilot to check. Preflighting this system requires that the radiator, coolant hoses, and expansion tank are checked for condition, freedom from leaks, and coolant level requirements.

Split flaps may be used on some LSA designs. [Figure 14] These flaps hinge down from underneath the wing and inspecting these flaps requires the pilot to crouch and twist low for inspection. A suitable handheld mirror can facilitate inspection without undue twisting and bending. In an attempt to keep complexity to a minimum, flap control is typically a handle that actuates the flaps. A pilot should verify that the flaps extend and retract smoothly.

Before Start and Starting Engine

Once a pilot has completed the preflight inspection of the LSA, the pilot should properly seat themselves in the airplane ensuring that the rudder pedals can be exercised with full-range movement without over-reaching. Seat belts should be checked for proper position and security. The pilot should continue to use the POH checklists. Starting newer generation LSA engines can be quite simple and only require the pull of the choke and a twist of the ignition switch. If the LSA is equipped with a standard certificated engine, starting procedures are normal and routine. The canopy or doors of an LSA may have quite different latching mechanisms than standard airworthiness airplanes. Practice latching and unlatching the doors or canopy to ensure that understanding is complete. Having a gull-wing door or sliding canopy “pop” open in flight can become an emergency in seconds.

Taxi

LSAs may have a full-castoring or steerable nose-wheel, or a tailwheel if equipped with conventional gear. In order to taxi a full-castoring nose-wheel equipped airplane, the use of differential brakes is required. This type of nose-wheel can require practice to keep the airplane on the centerline while minimizing brake application or damage to the tires. If the taxi speed is too slow, application of a brake can cause the aircraft to pivot to a stop, rather than adjust in direction. This results in excessive brake and tire wear. If the speed is too fast, excessive brake wear is likely.Transitioning into an LSA with conventional gear (tailwheel) should occur initially during no-wind conditions. Due to its light weight the airplane, requires the development of the proper flight control responses before operations in any substantial wind.

Takeoff and Climb

Takeoff and climb performance of LSAs can be spirited as they typically have a high horsepower-to-weight ratio and accelerate quickly. Due to design requirements for low stall speeds, LSAs typically have low rotation and climb speeds with impressive climb rates. Like other airplanes, the pilot should be flying the published speeds as given in the airplane’s POH. Stick (yoke or stoke) forces tend to be light, which may lead a transitioning pilot to initially over-control. The key is to relax, have reasonable patience, and input only appropriate flight control pressures needed to get the required response. If a transitioning pilot is inducing excessive control inputs, they should minimize flight control pressures, set attitudes based on outside references, and allow the airplane to settle.

During climbs, visibility over the nose may be difficult in some LSAs. As always, it is important to properly clear the airspace for traffic and other hazards. Occasionally lowering the airplane’s nose to get a good look out toward the horizon is important for managing flight safety. Shallow banked turns in both directions of 10° to 20° also allow for clearing. Because flight control pressures tend to be light, it is easy to get in the habit of flying with a light-sport airplane out of trim. This is to be avoided. Trim off any flight control pressures. This allows the pilot to focus as much time as possible looking outside.

Cruise

After leveling off at cruise altitude, the airplane should be allowed to accelerate to cruise speed, reduce power to cruise rpm, adjust pitch, and then trim off any flight control pressures. [Figure 15] The first time a transitioning pilot sees cruise rpm setting of 4,800 rpm (or as recommended), they may have a sense that the engine is turning too fast; however, remember that the engine has gear-reduction drive and the propeller is turning much slower. If the LSA is equipped with a standard aircraft engine, rpm should be in a range comparable to airplanes the transitioning pilot is used to. The pilot should refer to the Cruise Checklist to ensure that the airplane is properly configured.

In slower cruise flight, stick forces are likely to be light; therefore, correction to pitch and roll attitudes should be made with light pressures. Excess pressure used to correct a deviation may cause a series of pilot-induced oscillations. The pilot should use fingertip pressures only and not use a wrapped palm of the hand. Stick forces can change dramatically as airspeed changes. For example, what could be considered light control pressures at 80 knots may become quite stiff at 100 knots. A flight instructor-S or flight instructor-A experienced in the light-sport airplane is able to demonstrate this effect, which is dependent on the specific model of LSA.

LSA maneuvers such as steep turns, slow flight, and stalls are typical. These maneuvers should be practiced as part of a good transition training program. Steep turns in LSA airplanes tend to be quite easy to perform with precision. Light flight control pressures, stick mounted trim (if installed), and highly differential ailerons (if part of the airplane’s design), make the maneuvers seem simpler than in heavier airplanes. Basic aerodynamics applies to any airplane. Factors, such as over-banking tendency, are still prevalent and should be expected.

Slow flight in LSAs is accomplished at slower airspeeds than standard airworthiness airplanes since stall speeds tend to be well below the 45-knot limit. Practicing slow flight demonstrates the unique capability of LSAs. Recovery from power-off stalls involves lowering the nose. Application of power puts the airplane back flying. However, a pilot should understand that control pressures tend to be light, and an aggressive forward movement of the elevator is generally not required. In addition, proper application of rudder to compensate for propeller forces is required, and retraction of any flap should be completed prior to reaching VFE, which occurs quickly if full power and nose down pitch attitude are maintained. Power-on stalls can result in a very high nose-up attitude unless the airplane is adequately slowed down prior to the maneuver. In addition, some manufacturers limit pitch attitudes to 30° during power-on stalls. If aggressive pitch attitudes are coupled with uncoordinated rudder inputs, spin entry is likely to be quick and aggressive.

Depending on the LSA design, especially those airplanes which use control tubes rather than wires and pulleys, flight in turbulence may couple motion to the stick rather distinctively. If a transitioning pilot’s flight experience is only with airplanes that have control cables and pulleys, the first flight in turbulence may be disconcerting; however, once the pilot becomes familiar with the control sensations induced by the turbulence, it only becomes another means for the pilot to feel the airplane.

Approach and Landing

Approach and landing in an LSA is routine and comfortable. Speeds in the pattern tend to be in the 60-knot range. Flap limit airspeeds tend to be lower in LSAs than standard airworthiness airplanes, so managing airspeed is important. Light control forces require smooth application of control pressures to avoid over-controlling. Pitch and power are the same in an LSA as in a standard airworthiness airplane.

The weight limit of light-sport airplanes makes crosswind landings an important subject to focus on. The pilot should realize that strong gusty crosswind conditions may exceed the airplane’s control capability resulting in loss of control during the landing. Manufacturers place a maximum demonstrated crosswind speed in the POH, and until sufficient practice and experience is gained in the airplane, a transitioning pilot should have personal minimums that do not approach the manufacturer’s demonstrated crosswind speed. Control application does not change for crosswind technique in an LSA. However, the LSA’s weight, slow landing speeds, and light control forces can result in a pilot making control deflections that exceed those necessary to compensate for the crosswind.

Emergencies

While an LSA is designed to be simple, a complete knowledge of its systems is needed such that a transitioning pilot is able to respond properly to any emergency.

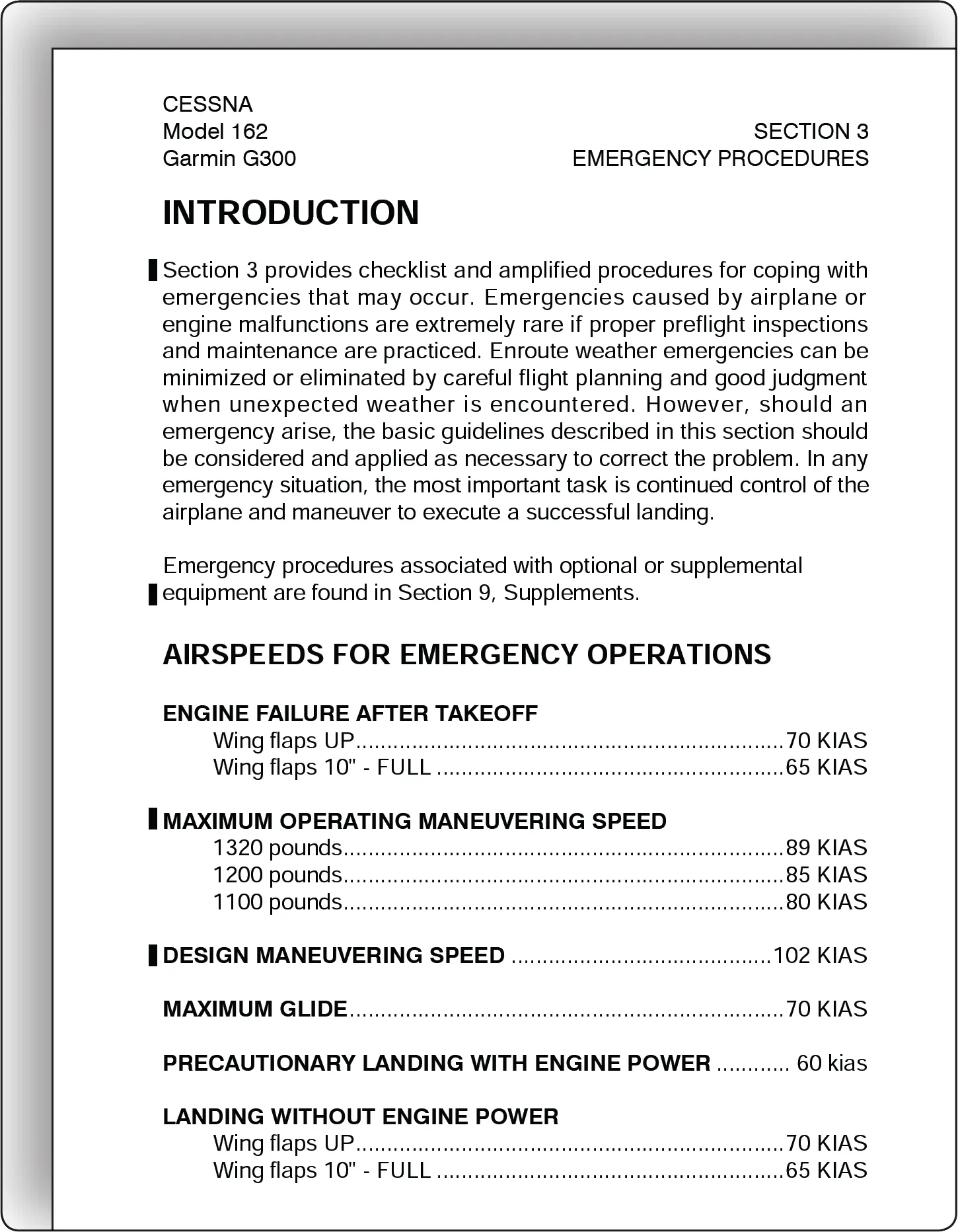

The airplane’s POH describes the appropriate responses to the various emergency situations that may be encountered. [Figure 16] Consider a few examples: the EFIS is displaying a red “X” across the airspeed tape, electric trim runaway, or control system failure. The pilot should be able to respond to immediate action items from memory and locate emergency procedures quickly. In the example of trim runaway, the pilot needs to quickly assess the trim runaway condition, locate and depress the trim disconnect (if installed), or pull the trim power circuit breaker. Then depending on control forces required to maintain pitch attitude, the pilot may need to make a no-flap landing due to the flap pitching moments. If the EFIS “blanks” out and POH recovery procedures do not reset the EFIS, an LSA pilot may have to be prepared to land without airspeed, altitude, or vertical speed information. An effective training program covers these emergency procedures.

Post-Flight

After the airplane has been shutdown, tied-down, and secured, the pilot should conduct a complete post-flight inspection. Any squawks or discrepancies should be noted and reported to maintenance. Transitioning pilots should insist on a training debriefing where critique and planning for the next lesson takes place. Documentation of the pilot’s progress should be noted in the student’s records.

Key Points

LSAs with an open flight deck, easy build characteristics, low cost, and simplicity of operation and maintenance tend to be less aerodynamic and incur more drag. When combined with their low mass and inertia, these LSAs tend to decelerate rapidly when power is reduced. When attempting a crosswind landing in a high-drag LSA, a rapid reduction in airspeed prior to touchdown may result in a loss of rudder and/or aileron control, which may push the aircraft off of the runway heading. To avoid loss of control, maintain airspeed during the approach. When power is reduced, it may be necessary to lower the nose of the aircraft to a fairly low pitch attitude in order to maintain airspeed.

If the pilot makes a power-off approach to landing, the approach angle will be high and the landing flare will need to be close to the ground with minimum float. This is because the aircraft will lose airspeed quickly in the flare and will not float like a more efficiently designed aircraft. Too low of an airspeed during the landing flare may lead to insufficient energy to arrest the descent and may result in a hard landing. Maintaining power during the approach will result in a reduced angle of attack and will extend the landing flare allowing more time to make adjustments to the aircraft during the landing. Always remember that rapid power reductions require an equally rapid reduction in pitch attitude to maintain airspeed.

In the event of an engine failure in an LSA, quickly transition to the required nose-down flight attitude in order to maintain airspeed. For example, if the aircraft has a power-off glide angle of 30 degrees below the horizon, position the aircraft to a nose-down 30 degree attitude as quickly as possible. The higher the pitch attitude is when the engine failure occurs, the quicker the aircraft will lose airspeed and the more likely the aircraft is to stall. Should a stall occur, decrease the aircraft’s pitch attitude rapidly in order to increase airspeed to allow for a recovery. Stalls that occur at low altitudes are especially dangerous because the closer to the ground the stall occurs, the less time there is to recover. For this reason, when climbing at a low altitude, excessive pitch attitude is discouraged.