The rotor system is the rotating part of a helicopter which generates lift. The rotor consists of a mast, hub, and rotor blades. The mast is a hollow cylindrical metal shaft which extends upwards from and is driven and sometimes supported by the transmission. At the top of the mast is the attachment point for the rotor blades called the hub. The rotor blades are then attached to the hub by any number of different methods. Main rotor systems are classified according to how the main rotor blades are attached and move relative to the main rotor hub. There are three basic classifications: semirigid, rigid, or fully articulated. Some modern rotor systems, such as the bearingless rotor system, use an engineered combination of these types.

Semirigid Rotor System

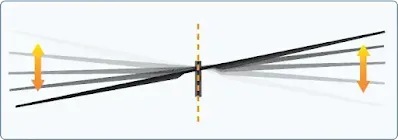

A semirigid rotor system is usually composed of two blades that are rigidly mounted to the main rotor hub. The main rotor hub is free to tilt with respect to the main rotor shaft on what is known as a teetering or flapping hinge. This allows the blades to flap together as a unit. As one blade flaps up, the other flaps down. Since there is no vertical drag hinge, lead/ lag forces are absorbed and mitigated by blade bending. The semirigid rotor is also capable of feathering, which means that the pitch angle of the blade changes. This is made possible by the feathering hinge. [Figure 1]

|

| Figure 1. The teetering hinge allows the main rotor hub to tilt, and the feathering hinge enables the pitch angle of the blades to change |

If the semirigid rotor system is an underslung rotor, the center of gravity (CG) is below where it is attached to the mast. This underslung mounting is designed to align the blade’s center of mass with a common flapping hinge so that both blades’ centers of mass vary equally in distance from the center of rotation during flapping.

The rotational speed of the system tends to change, but this is restrained by the inertia of the engine and flexibility of the drive system. Only a moderate amount of stiffening at the blade root is necessary to handle this restriction. Simply put, underslinging effectively eliminates geometric imbalance. [Figure 2]

|

| Figure 2. With an underslung rotor, the center of gravity (CG) remains in the same approximate location relative to the mast before and after rotor tilt |

The underslung rotor system mitigates the lead/lag forces by mounting the blades slightly lower than the usual plane of rotation, so the lead/lag forces are minimized. As the blades cone upward, the center of pressures of the blades are almost in the same plane as the hub. Whatever stresses are remaining bend the blades for compliance.

Helicopters with semirigid rotors are vulnerable to a condition known as mast bumping which can cause the rotor flap stops to shear the mast. The mechanical design of the semirigid rotor system dictates downward flapping of the blades must have some physical limit. Mast bumping is the result of excessive rotor flapping. Each rotor system design has a maximum flapping angle. If flapping exceeds the design value, the static stop will contact the mast. The static stop is a component of the main rotor providing limited movement of strap fittings and a contoured surface between the mast and hub. It is the violent contact between the static stop and the mast during flight that causes mast damage or separation. This contact must be avoided at all costs.

Mast bumping is directly related to how much the blade system flaps. In straight and level flight, blade flapping is minimal, perhaps 2° under usual flight conditions. Flapping angles increase slightly with high forward speeds, at low rotor rpm, at high-density altitudes, at high gross weights, and when encountering turbulence. Maneuvering the aircraft in a sideslip or during low-speed flight at extreme CG positions can induce larger flapping angles.

Rigid Rotor System

The rigid rotor system shown in Figure 3 is mechanically simple, but structurally complex because operating loads must be absorbed in bending rather than through hinges. In this system, the blade roots are rigidly attached to the rotor hub. Rigid rotor systems tend to behave like fully articulated systems through aerodynamics, but lack flapping or lead/ lag hinges. Instead, the blades accommodate these motions by bending. They cannot flap or lead/lag, but they can be feathered. As advancements in helicopter aerodynamics and materials continue to improve, rigid rotor systems may become more common because the system is fundamentally easier to design and offers the best properties of both semirigid and fully articulated systems.

|

| Figure 3. Four-blade hingeless (rigid) main rotor. Rotor blades are comprised of glass fiber reinforced material. The hub is a single piece of forged rigid titanium |

The rigid rotor system is very responsive and is usually not susceptible to mast bumping like the semirigid or articulated systems because the rotor hubs are mounted solid to the main rotor mast. This allows the rotor and fuselage to move together as one entity and eliminates much of the oscillation usually present in the other rotor systems. Other advantages of the rigid rotor include a reduction in the weight and drag of the rotor hub and a larger flapping arm, which significantly reduces control inputs. Without the complex hinges, the rotor system becomes much more reliable and easier to maintain than the other rotor configurations. A disadvantage of this system is the quality of ride in turbulent or gusty air. Because there are no hinges to help absorb the larger loads, vibrations are felt in the cabin much more than with other rotor head designs.

There are several variations of the basic three rotor head designs. The bearingless rotor system is closely related to the articulated rotor system, but has no bearings or hinges. This design relies on the structure of blades and hub to absorb stresses. The main difference between the rigid rotor system and the bearingless system is that the bearingless system has no feathering bearing—the material inside the cuff is twisted by the action of the pitch change arm. Nearly all bearingless rotor hubs are made of fiber-composite materials. The differences in handling between the types of rotor system are summarized in Figure 4.

| System Type | Advantages | Disadvantages |

|---|---|---|

| Articulated | Good control response | High aerodynamic drag. More complex, greater cost. |

| Semirigid (Teetering, Underslung, or See-Saw) | Simple, easy to hangar due to two blades | Reaction to control input not as quick as articulated head. Vibration can be higher than multibladed articulatedsystems. |

| Rigid | Simple design, crisp response | Higher vibration than articulated rotor. |

Fully Articulated Rotor System

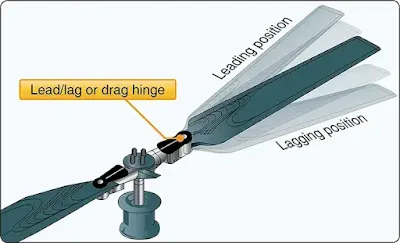

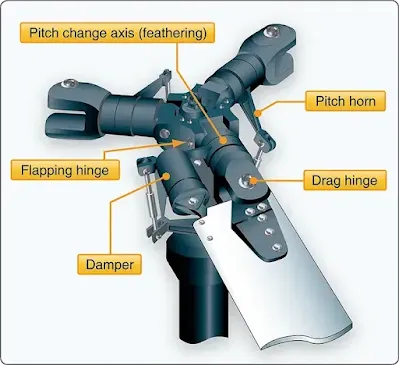

Fully articulated rotor systems allow each blade to lead/lag (move back and forth in plane), flap (move up and down about an inboard mounted hinge) independent of the other blades, and feather (rotate about the pitch axis to change lift). [Figures 5 and 6] Each of these blade motions is related to the others. Fully articulated rotor systems are found on helicopters with more than two main rotor blades.

|

| Figure 5. Lead/lag hinge allows the rotor blade to move back and forth in plane |

|

| Figure 6. Fully articulated flapping hub |

As the rotor spins, each blade responds to inputs from the control system to enable aircraft control. The center of lift on the whole rotor system moves in response to these inputs to effect pitch, roll, and upward motion. The magnitude of this lift force is based on the collective input, which changes pitch on all blades in the same direction at the same time. The location of this lift force is based on the pitch and roll inputs from the pilot. Therefore, the feathering angle of each blade (proportional to its own lifting force) changes as it rotates with the rotor, hence the name “cyclic control.”

As the lift on a given blade increases, it tends to flap upwards. The flapping hinge for the blade permits this motion and is balanced by the centrifugal force of the weight of the blade, which tries to keep it in the horizontal plane. [Figure 7]

|

| Figure 7. Fully articulated rotor blade with flapping hinge |

Either way, some motion must be accommodated. The centrifugal force is nominally constant; however, the flapping force is affected by the severity of the maneuver (rate of climb, forward speed, aircraft gross weight). As the blade flaps, its CG changes. This changes the local moment of inertia of the blade with respect to the rotor system and it speeds up or slows down with respect to the rest of the blades and the whole rotor system. This is accommodated by the lead/lag or drag hinge, shown in Figure 8, and is easier to visualize with the classical ‘ice skater doing a spin’ image. As the skater moves her arms in, she spins faster because her inertia changes but her total energy remains constant (neglect friction for purposes of this explanation). Conversely, as her arms extend, her spin slows. This is also known as the conservation of angular momentum. An in-plane damper typically moderates lead/lag motion.

|

| Figure 8. Drag hinge |

Following a single blade through a single rotation beginning at some neutral position, as load increases from increased feathering, it flaps up and leads forward. As it continues around, it flaps down and lags backward. At the lowest point of load, it is at its lowest flap angle and also at its most ‘rearward’ lag position. Because the rotor is a large, rotating mass, it behaves somewhat like a gyroscope. The effect of this is that a control input is usually realized on the attached body at a position 90° prior to the control input displacement in the axis of rotation. This is accounted for by the designers through placement of the control input to the rotor system so that a forward input of the cyclic control stick results in a nominally forward motion of the aircraft. The effect is made transparent to the pilot.

Older hinge designs relied on conventional metal bearings. By basic geometry, this precludes a coincident flapping and lead/ lag hinge and is cause for recurring maintenance. Newer rotor systems use elastomeric bearings, arrangements of rubber and steel that can permit motion in two axes. Besides solving some of the above-mentioned kinematic issues, these bearings are usually in compression, can be readily inspected, and eliminate the maintenance associated with metallic bearings.

Elastomeric bearings are naturally fail-safe, and their wear is gradual and visible. The metal-to-metal contact of older bearings and the need for lubrication is eliminated in this design.

Tandem Rotor

Tandem rotor (sometimes referred to as dual rotor) helicopters have two large horizontal rotor assemblies; a twin rotor system, instead of one main assembly, and a smaller tail rotor. [Figure 9] Single rotor helicopters need an anti-torque system to neutralize the twisting momentum produced by the single large rotor. Tandem rotor helicopters, however, use counter-rotating rotors, with each canceling out the other’s torque. Counter-rotating rotor blades will not collide with and destroy each other if they flex into the other rotor’s pathway. This configuration also has the advantage of being able to hold more weight with shorter blades, since there are two sets. Also, all of the power from the engines can be used for lift, whereas a single rotor helicopter uses power to counter the torque.

|

| Figure 9. Tandem rotor heads |

Coaxial Rotors

A coaxial rotor system is a pair of rotors mounted on the same shaft but turning in opposite directions. This design eliminates the need for a tail rotor or other antitorque mechanisms, and since the blades turn in opposite directions, the effects of dissymmetry of lift are avoided. The main disadvantage of coaxial rotors is the increased mechanical complexity of the rotor system. Numerous Russian helicopters, such as the Kaman Ka-31 and Ka-50, along with the Sikorsky experimental X2 use a coaxial rotor design.

Intermeshing Rotors

An intermeshing rotor system is a set of two rotors turning in the opposite directions with each rotor mast mounted on the helicopter with a slight angle, so the blades intermesh without colliding. This design also eliminates the need for an antitorque system, which provides more engine power for lift. However, neither rotor lifts directly vertical which reduces each rotor’s efficiency. The Kaman HH-43, which was used by the USAF in a firefighting role and the Kaman K-MAX are examples of an intermeshing rotor systems.