Low Altitude Engine Failure Scenarios

In OEI flight at low altitudes and airspeeds such as the initial climb after takeoff, pilots should operate the airplane so as to guard against the three major accident factors: (1) loss of directional control, (2) loss of performance, and (3) loss of flying speed. All have equal potential to be lethal. Loss of flying speed is not a factor, however, when the airplane is operated with due regard for directional control and performance.

A takeoff or go-around is the most critical time to suffer an engine failure. The airplane will be slow, close to the ground, and may even have landing gear and flaps extended. Altitude and time is minimal. Until feathered, the propeller of the failed engine is windmilling, producing a great deal of drag and yawing tendency. Airplane climb performance is marginal or even non-existent, and obstructions may lie ahead. An emergency contingency plan and safety brief should be clearly understood well before the takeoff roll commences.

An engine failure before a predetermined airspeed or point results in an aborted takeoff. An engine failure after a certain airspeed and point, with the gear up, and climb performance assured result in a continued takeoff. With loss of an engine, it is paramount to maintain airplane control and comply with the manufacturer’s recommended emergency procedures. Complete failure of one engine shortly after takeoff can be broadly categorized into one of three following scenarios.

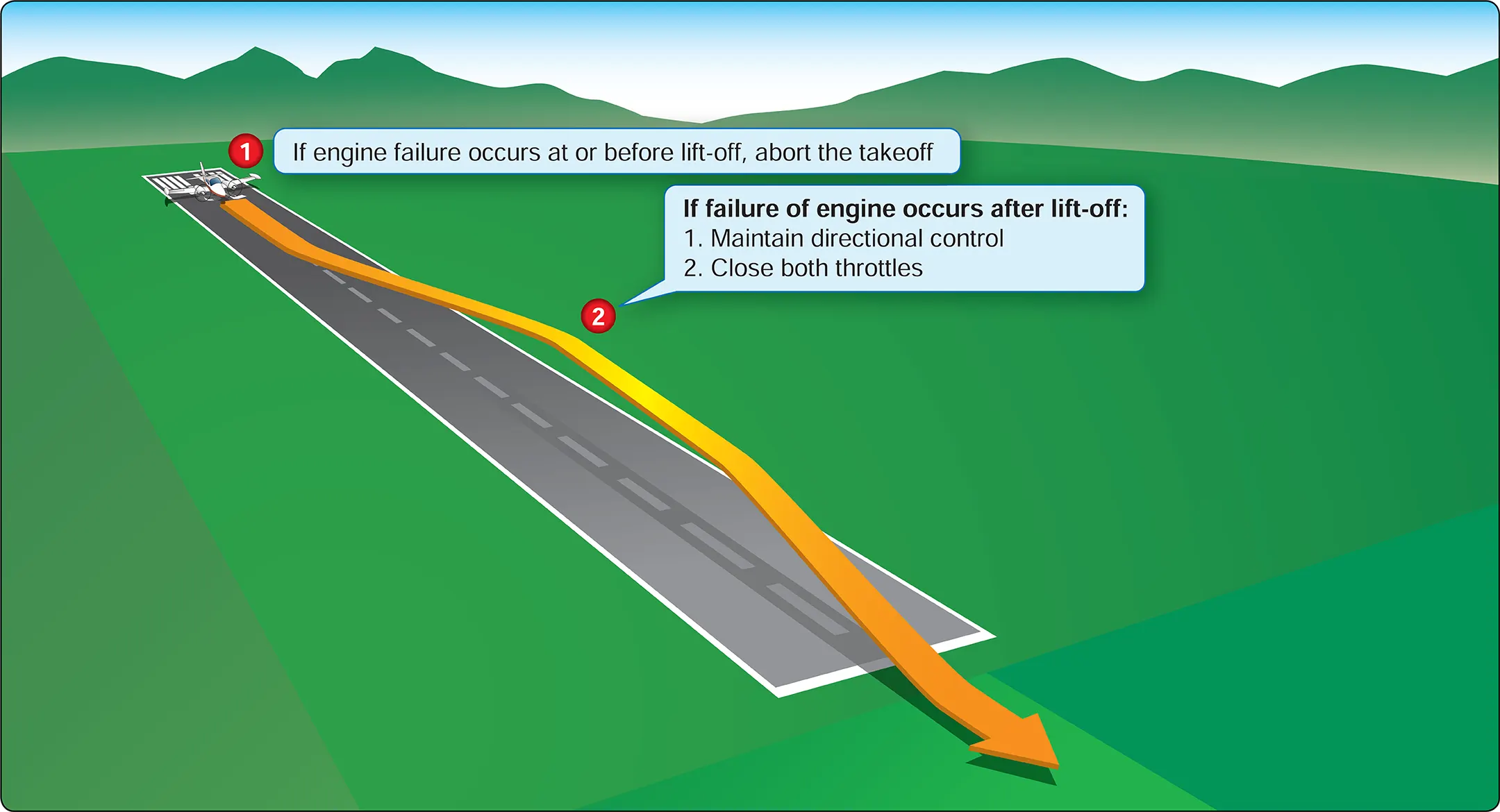

Landing Gear Down

If the engine failure occurs prior to selecting the landing gear to the UP position [Figure 1]: Keep the nose as straight as possible, close both throttles, adjust pitch attitude to maintain adequate airspeed, and descend to the runway. Concentrate on a normal landing and do not force the aircraft on the ground. Land on the remaining runway or overrun. Depending upon how quickly the pilot reacts to the sudden yaw, the airplane may run off the side of the runway by the time action is taken. There are really no other practical options.

As discussed earlier, the chances of maintaining directional control while retracting the flaps (if extended), landing gear, feathering the propeller, and accelerating are minimal. On some airplanes with a single-engine-driven hydraulic pump, failure of that engine means the only way to raise the landing gear is to allow the engine to windmill or to use a hand pump. This is not a viable alternative during takeoff.

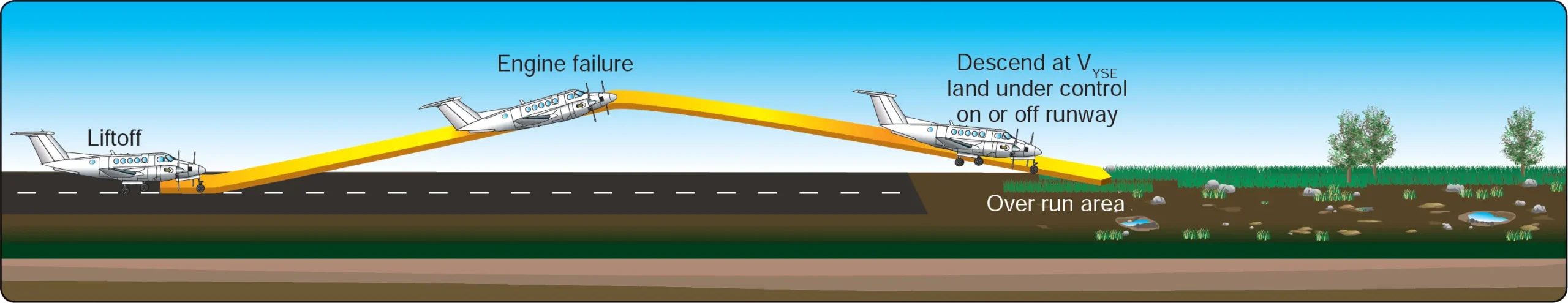

Landing Gear Control Selected Up, Single-Engine Climb Performance Inadequate

When operating near or above the single-engine ceiling and an engine failure is experienced shortly after lift-off, a landing needs to be accomplished on whatever essentially lies ahead. [Figure 2]

There is also the option of continuing ahead, in a descent at VYSE with the remaining engine producing power, as long as the pilot is not tempted to remain airborne beyond the airplane’s performance capability. Remaining airborne and bleeding off airspeed in a futile attempt to maintain altitude is almost invariably fatal. Landing under control is paramount. The greatest hazard in a single-engine takeoff is attempting to fly when it is not within the performance capability of the airplane to do so. An accident is inevitable.

Analysis of engine failures on takeoff reveals a very high success rate of off-airport engine inoperative landings when the airplane is landed under control. Analysis also reveals a very high fatality rate in stall spin accidents when the pilot attempts flight beyond the performance capability of the airplane.

As mentioned previously, if the airplane’s landing gear retraction mechanism is dependent upon hydraulic pressure from a certain engine-driven pump, failure of that engine can mean a loss of hundreds of feet of altitude as the pilot either windmills the engine to provide hydraulic pressure to raise the gear or raises it manually with a backup pump.

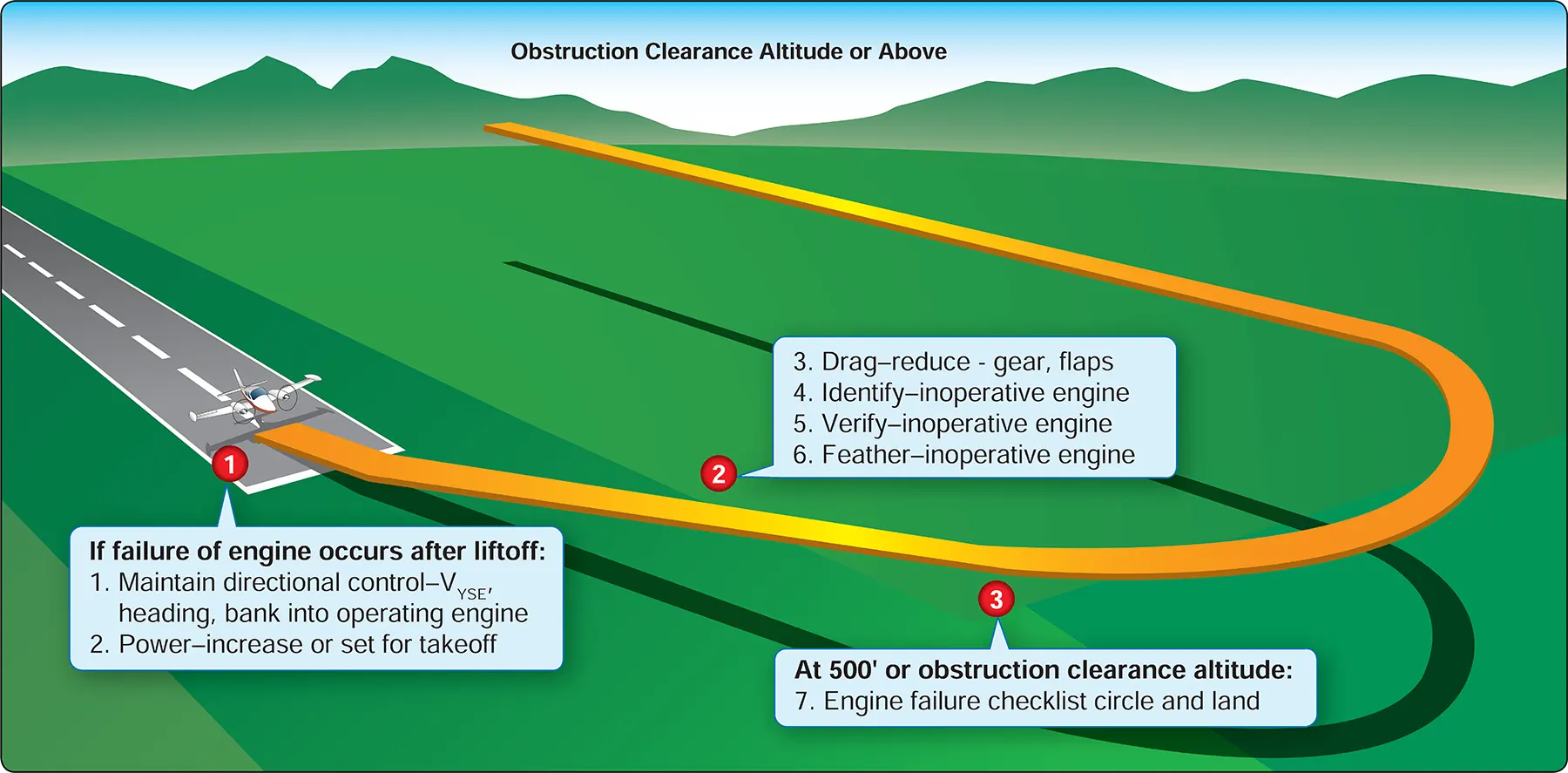

Landing Gear Control Selected Up, Single-Engine Climb Performance Adequate

If the single-engine rate of climb is adequate, the procedures for continued flight should be followed. [Figure 3] There are four areas of concern: control, configuration, climb, and checklist.

Control

The first consideration following engine failure during takeoff is to maintain control of the airplane. Maintaining directional control with prompt and often aggressive rudder application and STOPPING THE YAW is critical to the safety of flight. Ensure that airspeed stays above VMC. If the yaw cannot be controlled with full rudder applied, reducing thrust on the operative engine is the only alternative. Attempting to correct the roll with aileron without first applying rudder increases drag and adverse yaw and further degrades directional control. After rudder is applied to stop the yaw, a slight amount of aileron should be used to bank the airplane toward the operative engine.

This is the most efficient way to control the aircraft, minimize drag, and gain the most performance. Control forces, particularly on the rudder, may be high. The pitch attitude for VYSE has to be lowered from that of VY. At least 5° and a maximum of 10° of bank toward the operative engine should be used initially to stop the yaw and maintain directional control. This initial bank input is held only momentarily, just long enough to establish or ensure directional control. Climb performance suffers when bank angles exceed approximately 2 or 3°, but obtaining and maintaining VYSE and directional control are paramount. Trim should be adjusted to lower the control forces.

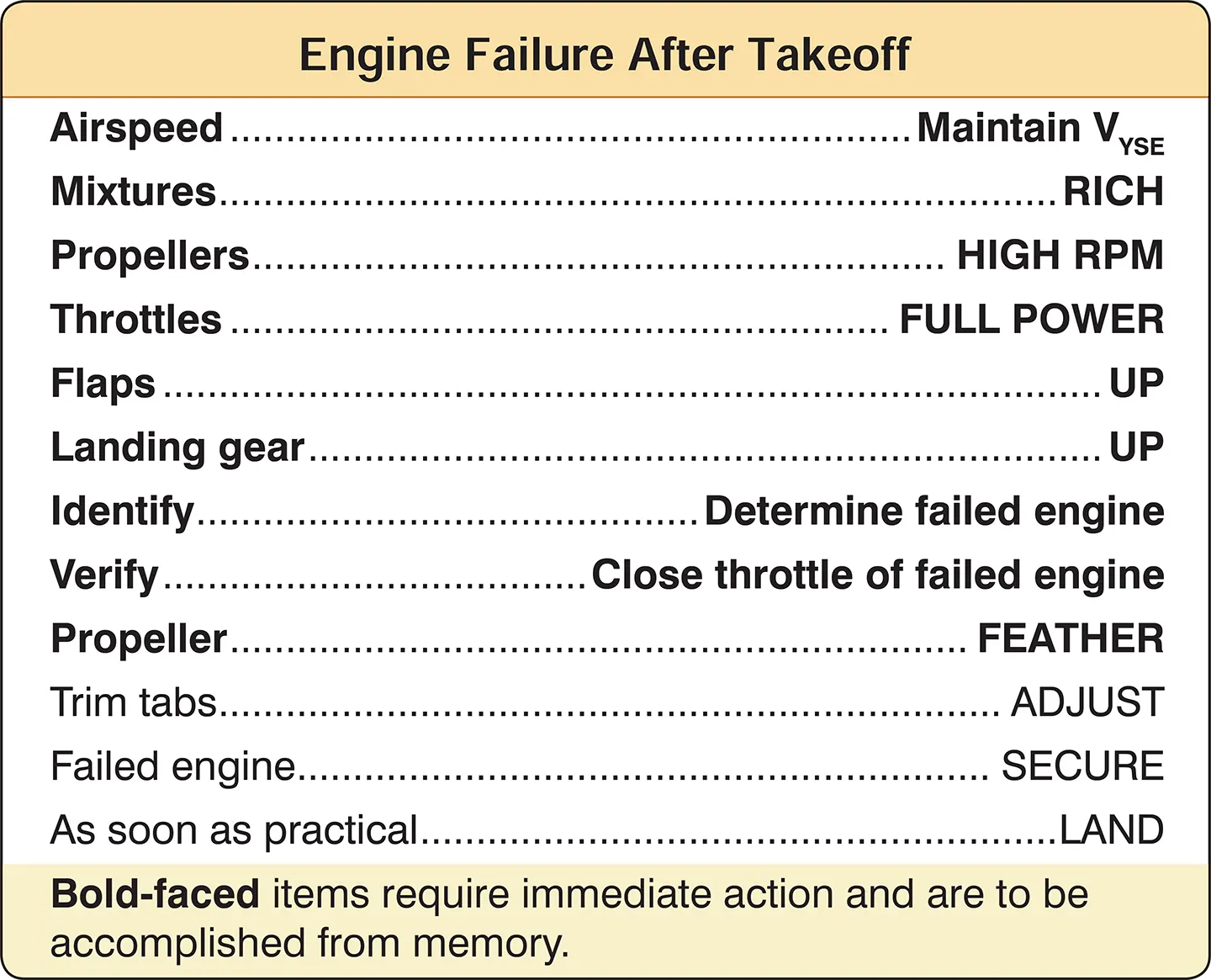

Configuration

The memory items from the engine failure after takeoff checklist should be promptly executed to configure the airplane for climb. [Figure 4] The specific procedures to follow are found in the AFM/POH and checklist for the particular airplane. Most direct the pilot to assume VYSE, set takeoff power, retract the flaps and landing gear, identify, verify, and feather the failed engine. (On some airplanes, the landing gear is to be retracted before the flaps.)

The “identify” step is for the pilot to initially identify the failed engine. Confirmation on the engine gauges may or may not be possible, depending upon the failure mode. Identification should be primarily through the control inputs required to maintain straight flight, not the engine gauges. The “verify” step directs the pilot to retard the throttle of the engine thought to have failed. No change in performance when the suspected throttle is retarded is verification that the correct engine has been identified as failed. The corresponding propeller control should be brought fully aft to feather the engine.

Climb

As soon as directional control is established and the airplane configured for climb, the bank angle should be reduced to that producing best climb performance. Without specific guidance for zero sideslip, a bank of 2° and one-third to one-half ball deflection on the slip/skid indicator toward the operative engine is suggested. VYSE is maintained with pitch control. As turning flight reduces climb performance, climb should be made straight ahead or with shallow turns to avoid obstacles to an altitude of at least 400 feet AGL before attempting a return to the airport.

Checklist

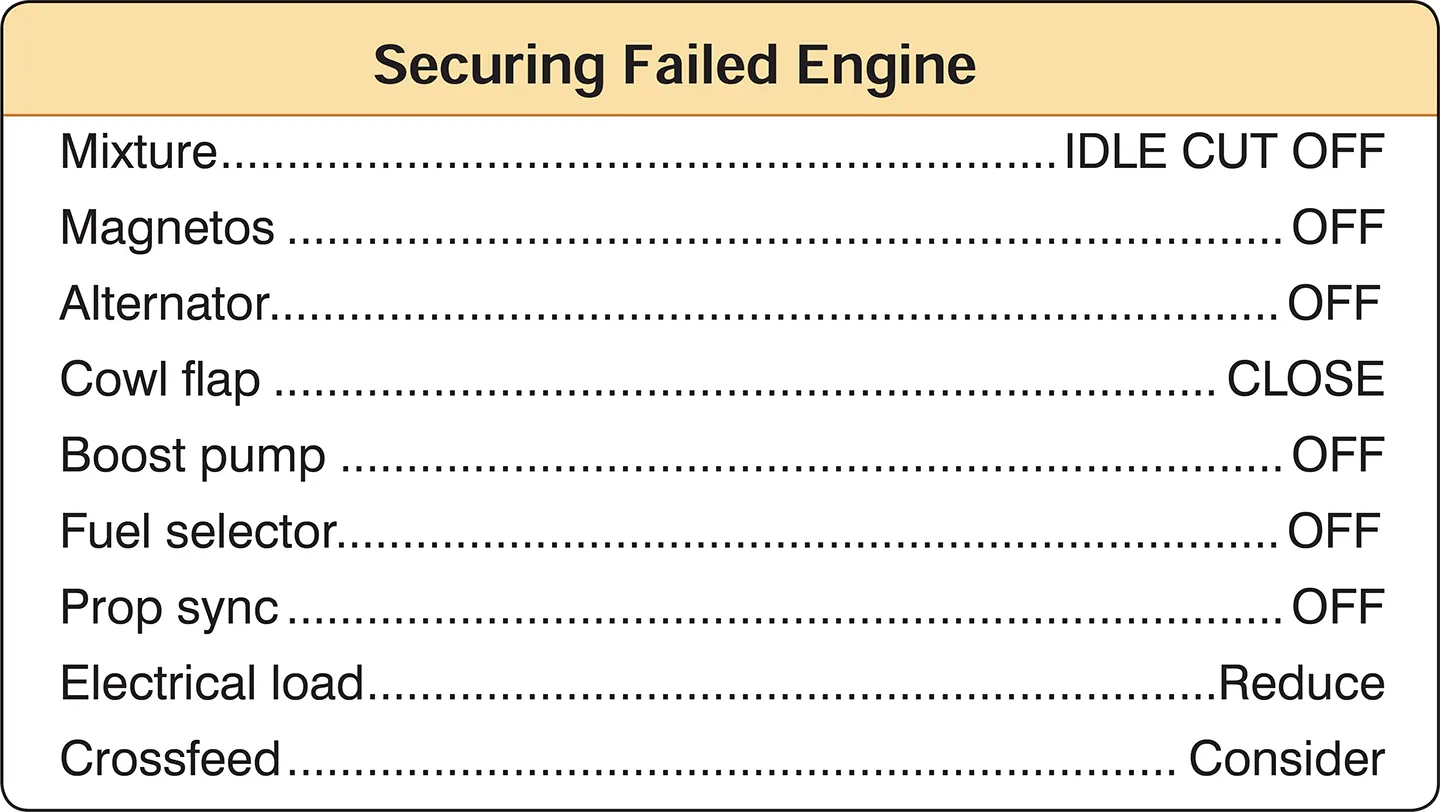

Having accomplished the memory items from the engine failure after takeoff checklist, the printed copy should be reviewed as time permits. The securing failed engine checklist should then be accomplished. [Figure 5] Unless the pilot suspects an engine fire, the remaining items should be accomplished deliberately and without undue haste. Airplane control should never be sacrificed to execute the remaining checklists. The priority items have already been accomplished from memory.

Other than closing the cowl flap of the failed engine, none of these items, if left undone, adversely affect airplane climb performance. There is a distinct possibility of actuating an incorrect switch or control if the procedure is rushed. The pilot should concentrate on flying the airplane and extracting maximum performance. If an ATC facility is available, an emergency should be declared.

The memory items in the engine failure after takeoff checklist may be redundant with the airplane’s existing configuration. For example, in the third takeoff scenario, the gear and flaps were assumed to already be retracted, yet the memory items included gear and flaps. This is not an oversight. The purpose of the memory items is to either initiate the appropriate action or to confirm that a condition exists. Action on each item may not be required in all cases. The memory items also apply to more than one circumstance. In an engine failure from a go-around, for example, the landing gear and flaps would likely be extended when the failure occurred.

The three preceding takeoff scenarios all include the landing gear as a key element in the decision to land or continue. With the landing gear selector in the DOWN position, for example, continued takeoff and climb is not recommended. This situation, however, is not justification to retract the landing gear the moment the airplane lifts off the surface on takeoff as a normal procedure. The landing gear should remain selected down as long as there is usable runway or overrun available to land on. The use of wing flaps for takeoff virtually eliminates the likelihood of a single-engine climb until the flaps are retracted.

There are two time-tested memory aids the pilot may find useful in dealing with engine-out scenarios. The first, “dead foot—dead engine” is used to assist in identifying the failed engine. Depending on the failure mode, the pilot will not be able to consistently identify the failed engine in a timely manner from the engine gauges. In maintaining directional control, however, rudder pressure is exerted on the side (left or right) of the airplane with the operating engine. Thus, the “dead foot” is on the same side as the “dead engine.” Variations on this saying include “idle foot—idle engine” and “working foot–working engine.”

The second memory aid has to do with climb performance. The phrase “raise the dead” is a reminder that the best climb performance is obtained with a very shallow bank, about 2° toward the operating engine. Therefore, the inoperative, or “dead” engine should be “raised” with a very slight bank.

Not all engine failures result in complete power loss. If there is a performance loss when the throttle of the affected engine is retarded, some power is still available. In this case, the pilot may consider allowing the engine to run until the airplane reaches a safe altitude and airspeed for single-engine flight. While shutdown of a malfunctioning engine may prevent additional damage to the engine in certain circumstances, shutting down an engine that can still produce partial power may increase risk for an accident.

Engine Failure During Flight

Engine failures well above the ground are handled differently than those occurring at lower speeds and altitudes. Cruise airspeed allows better airplane control and altitude, which may permit time for a possible diagnosis and remedy of the failure. Maintaining airplane control, however, is still paramount. Airplanes have been lost at altitude due to apparent fixation on the engine problem to the detriment of flying the airplane.

Not all engine failures or malfunctions are catastrophic in nature (catastrophic meaning a major mechanical failure that damages the engine and precludes further engine operation). Many cases of power loss are related to fuel starvation, where restoration ofpower may be made with the selection of another tank. An orderly inventory of gauges and switches may reveal the problem. Carburetor heat or alternate air can be selected. The affected engine may run smoothly on just one magneto or at a lower power setting. Altering the mixture may help. If fuel vapor formation is suspected, fuel boost pump operation may be used to eliminate flow and pressure fluctuations.

Although it is a natural desire among pilots to save an ailing engine with a precautionary shutdown, the engine should be left running if there is any doubt as to needing it for further safe flight. Catastrophic failure accompanied by heavy vibration, smoke, blistering paint, or large trails of oil, on the other hand, indicate a critical situation. The affected engine should be feathered and the securing failed engine checklist completed. The pilot should divert to the nearest suitable airport and declare an emergency with ATC for priority handling.

Fuel crossfeed is a method of getting fuel from a tank on one side of the airplane to an operating engine on the other. Crossfeed is used for extended single-engine operation. If a suitable airport is close at hand, there is no need to consider crossfeed. If prolonged flight on a single-engine is inevitable due to airport non-availability, then crossfeed allows use of fuel that would otherwise be unavailable to the operating engine. It also permits the pilot to balance the fuel consumption to avoid an out-of-balance wing heaviness.

The AFM/POH procedures for crossfeed vary widely. Thorough fuel system knowledge is essential if crossfeed is to be conducted. Fuel selector positions and fuel boost pump usage for crossfeed differ greatly among multiengine airplanes. Prior to landing,crossfeed should be terminated and the operating engine returned to its main tank fuel supply.

If the airplane is above its single-engine absolute ceiling at the time of engine failure, it slowly loses altitude. The pilot should maintain VYSE to minimize the rate of altitude loss. This “drift down” rate is greatest immediately following the failure and decreases as the single-engine ceiling is approached. Due to performance variations caused by engine and propeller wear, turbulence, and pilot technique, the airplane may not maintain altitude even at its published single-engine ceiling. Any further rate of sink, however, would likely be modest.

An engine failure in a descent or other low power setting can be deceiving. The dramatic yaw and performance loss is absent. At very low power settings, the pilot may not even be aware of a failure. If a failure is suspected, the pilot should advance both engine mixtures, propellers, and throttles significantly, to the takeoff settings if necessary, to correctly identify the failed engine. The power on the operative engine can always be reduced later.