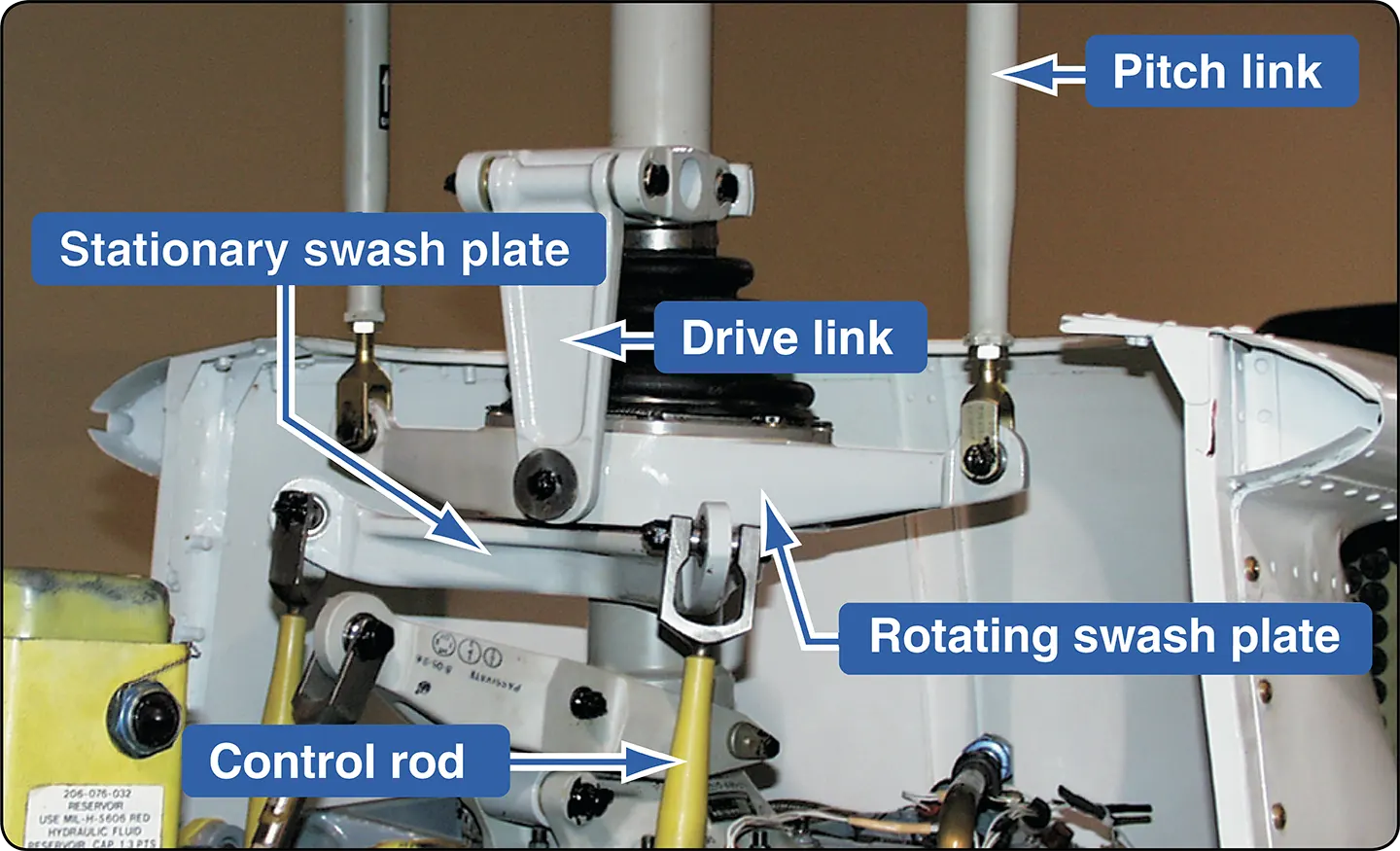

Swash Plate Assembly

The purpose of the swash plate is to convert stationary control inputs from the pilot into rotating inputs which can be connected to the rotor blades or control surfaces. It consists of two main parts: stationary swash plate and rotating swash plate. [Figure 1]

The stationary swash plate is mounted around the main rotor mast and connected to the cyclic and collective controls by a series of pushrods. It is restrained from rotating by an antidrive link but can tilt in all directions and move vertically. The rotating swash plate is mounted to the stationary swash plate by means of a uniball sleeve. It is connected to the mast by drive links and must rotate in constant relationship with the main rotor mast. Both swash plates tilt and slide up and down as one unit. The rotating swash plate is connected to the pitch horns by the pitch links.

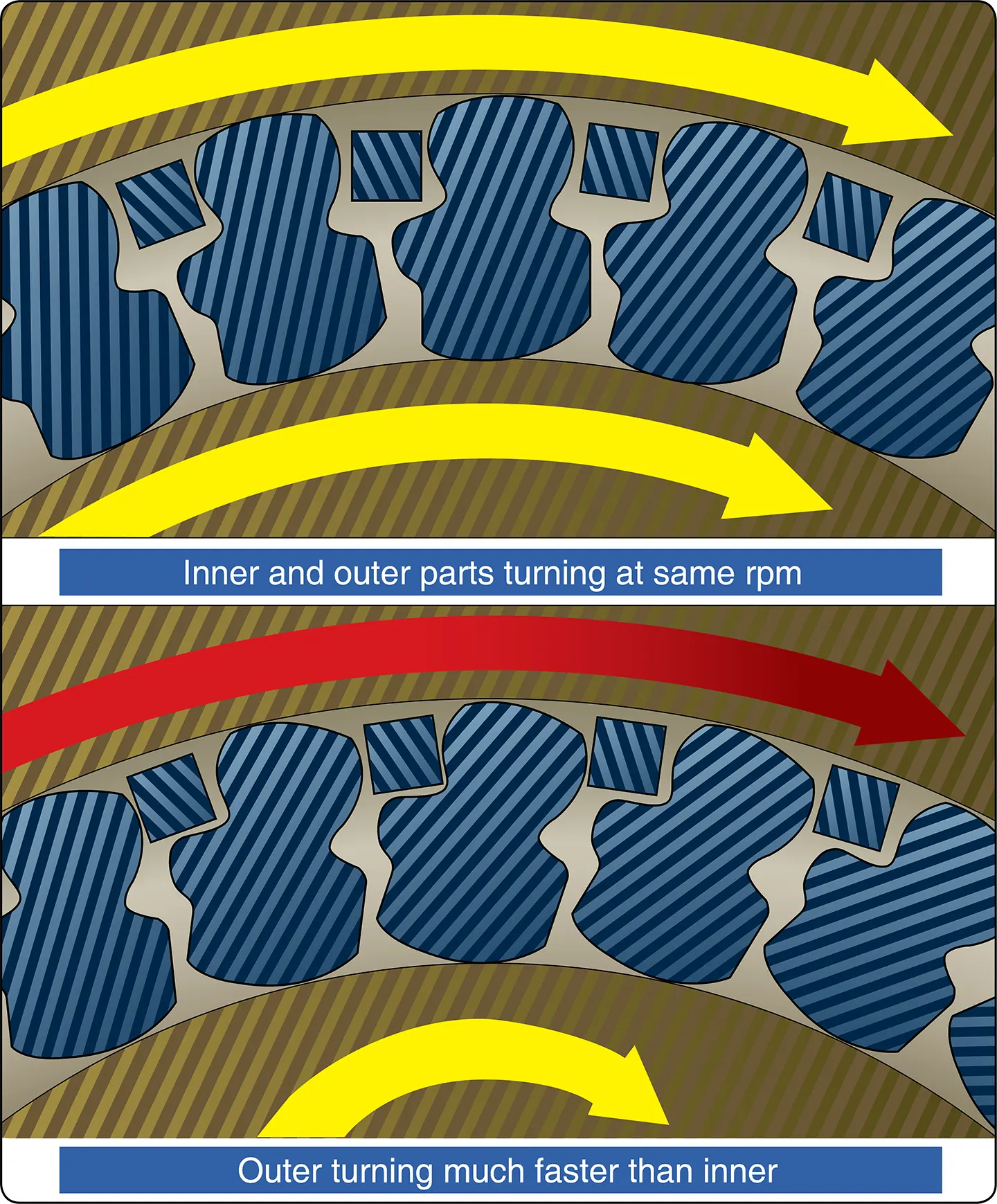

Freewheeling Unit

Since lift in a helicopter is provided by rotating airfoils, these airfoils must be free to rotate if the engine fails. The freewheeling unit automatically disengages the engine from the main rotor when engine revolutions per minute (rpm) is less than main rotor rpm. [Figure 2]

This allows the main rotor and tail rotor to continue turning at normal inflight speeds. The most common freewheeling unit assembly consists of a one-way sprag clutch located between the engine and main rotor transmission. This is usually in the upper pulley in a piston helicopter or mounted on the accessory gearbox in a turbine helicopter. When the engine is driving the rotor, inclined surfaces in the sprag clutch force rollers against an outer drum. This prevents the engine from exceeding transmission rpm. If the engine fails, the rollers move inward, allowing the outer drum to exceed the speed of the inner portion. The transmission can then exceed the speed of the engine. In this condition, engine speed is less than that of the drive system, and the helicopter is in an autorotative state.