The fuel system in a helicopter is made up of two groups of components: the fuel supply system and the engine fuel control system.

Fuel Supply System

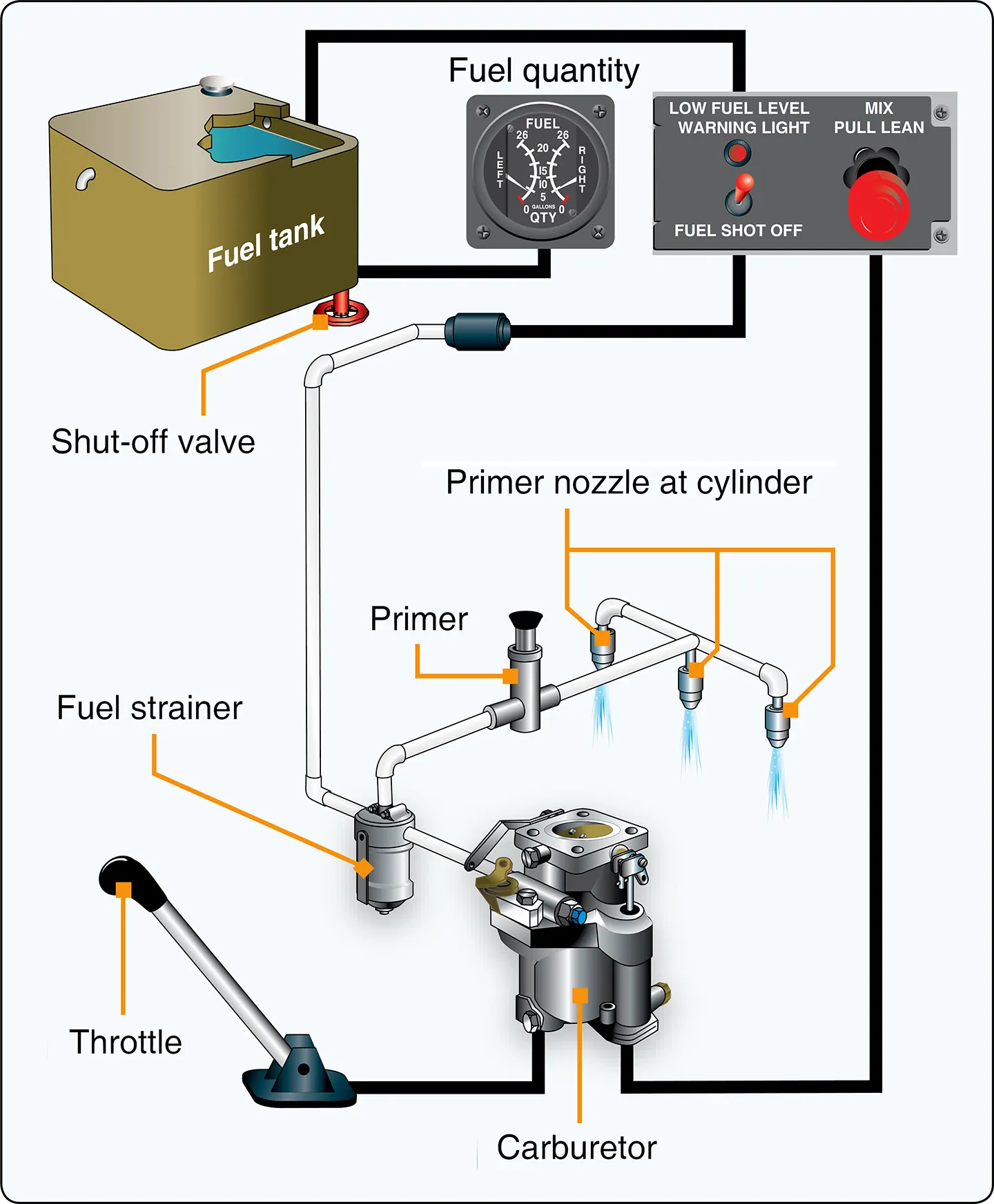

The supply system consists of a fuel tank or tanks, fuel quantity gauges, a shut-off valve, fuel filter, a fuel line to the engine, and possibly a primer and fuel pumps. [Figure 1]

The fuel tanks are usually mounted to the airframe as close as possible to the CG. This way, as fuel is burned off, there is a negligible effect on the CG. A drain valve located on the bottom of the fuel tank allows the pilot to drain water and sediment that may have collected in the tank. A fuel vent prevents the formation of a vacuum in the tank, and an overflow drain allows fuel to expand without rupturing the tank.

The fuel travels from the fuel tank through a shut-off valve, which provides a means to completely stop fuel flow to the engine in the event of an emergency or fire. The shut-off valve remains in the open position for all normal operations.

Most non-gravity feed fuel systems contain both an electric pump and a mechanical engine driven pump. The electrical pump is used to maintain positive fuel pressure to the engine pump and may also serve as a backup in the event of mechanical pump failure. The electrical pump is controlled by a switch in the cockpit.

The engine driven pump is the primary pump that supplies fuel to the engine and operates any time the engine is running. A fuel filter removes moisture and other sediment from the fuel before it reaches the engine. These contaminants are usually heavier than fuel and settle to the bottom of the fuel filter sump where they can be drained out by the pilot.

Some fuel systems contain a small hand-operated pump called a primer. A primer allows fuel to be pumped directly into the intake port of the cylinders prior to engine start. The primer is useful in cold weather when fuel in the carburetor is difficult to vaporize.

A fuel quantity gauge located on the pilot’s instrument panel shows the amount of fuel measured by a sensing unit inside the tank. Most fuel gauges will indicate in gallons or pounds, and must be accurate only when empty.

It is worth noting that in accordance with Title 14 of the Code of Federal Regulations (14 CFR) section 27.1337(b)(1), fuel quantity indicators “must be calibrated to read ‘zero’ during level flight when the quantity of fuel remaining in the tank is equal to the unusable fuel supply.” Therefore, it is of the utmost importance that the pilot or operator determines an accurate means of verifying partial or full fuel loads. It is always a good habit, if possible, to visually verify the fuel on board prior to flight and determine if adequate fuel is present for the duration of the flight.

Additionally, 14 CFR section 27.1305(l)(1) requires newer helicopters to have warning systems “provide a warning to the flight crew when approximately 10 minutes of usable fuel remains in the tank.” Caution should be used to eliminate unnecessary or erratic maneuvering that could cause interruption of fuel flow to the engine. Although these systems must be calibrated, never assume the entire amount is available. Many pilots have not reached their destinations due to poor fuel planning or faulty fuel indications.

Engine Fuel Control System

Regardless of the device, the reciprocating engine and the turbine engine both use the ignition and combustion of the fuel/air mix to provide the source of their power. Engine fuel control systems utilize several components to meter the proper amount of fuel necessary to produce the required amount of power. The fuel control system in concert with the air induction components combine the proper amount of fuel and air to be ignited in the combustion chamber. Refer to the Aeronautical Knowledge section for a detailed explanation and illustration.

Carburetor Ice

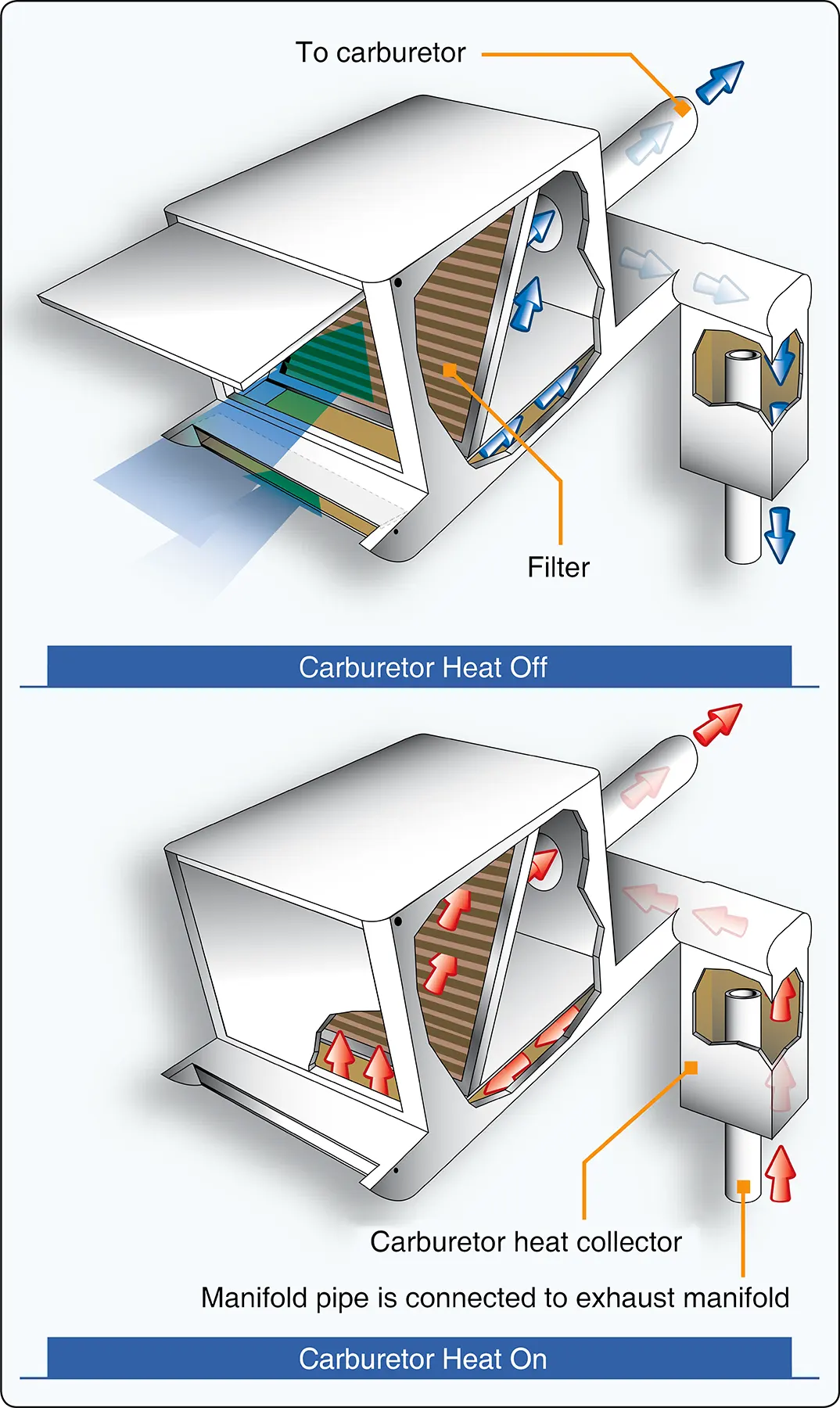

The effect of fuel vaporization and/or a decrease of air pressure in the venturi causes a rapid decrease in air temperature in the carburetor. If the air is moist, the water vapor in the air may condense causing ice to form in the carburetor. If ice is allowed to form inside the carburetor, engine failure is a very real possibility and the ability to restart the engine is greatly reduced.

Carburetor icing can occur during any phase of flight but is particularly dangerous when you are using reduced power, such as during a descent. You may not notice it during the descent until you try to add power. Indications of carburetor icing are a decrease in engine rpm or manifold pressure, the carburetor air temperature gauge indicating a temperature outside the safe operating range, and engine roughness. A reciprocating engine with a governor may mask the formation of carburetor ice since it will maintain a constant manifold pressure and rpm.

Since changes in rpm or manifold pressure can occur for a number of reasons, closely check the carburetor air temperature gauge when in possible carburetor icing conditions. Carburetor air temperature gauges are marked with a yellow caution arc or green operating arcs. In most cases, it is best to keep the needle out of the yellow arc or in the green arc.

This is accomplished by using a carburetor heat system, which eliminates the ice by routing air across a heat source, such as an exhaust manifold, before it enters the carburetor. [Figure 2] Refer to the RFM (see Rotorcraft Flight Manual) for the specific procedure as to when and how to apply carburetor heat.

Fuel Injection

In a fuel injection system, fuel and air are metered at the fuel control unit but are not mixed. The fuel is injected directly into the intake port of the cylinder where it is mixed with the air just before entering the cylinder. This system ensures a more even fuel distribution between cylinders and better vaporization, which in turn promotes more efficient use of fuel. Also, the fuel injection system eliminates the problem of carburetor icing and the need for a carburetor heat system.