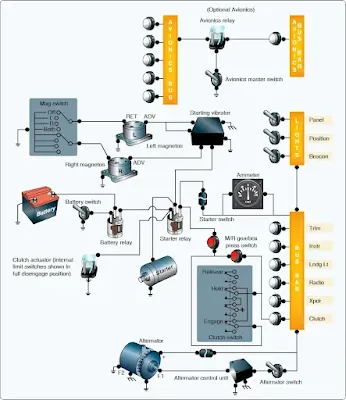

The electrical systems, in most helicopters, reflect the increased use of sophisticated avionics and other electrical accessories. [Figure] More and more operations in today’s flight environment are dependent on the aircraft’s electrical system; however, all helicopters can be safely flown without any electrical power in the event of an electrical malfunction or emergency.

Helicopters have either a 14- or 28-volt, direct-current electrical system. On small, piston powered helicopters, electrical energy is supplied by an engine-driven alternator by means of a belt and pulley system similar to that of an automobile. These alternators have advantages over older-style generators as they are lighter in weight, require lower maintenance, and maintain a uniform electrical output even at low engine rpm. (As a reminder, think of volts or voltage as the measure of electrical pressure in the system, analogous to pounds per square inch in water systems. Amperes is the measure of electrical quantity in the system or available. For example, a 100-amp alternator would be analogous to a 100 gallon per hour water pump.)

Turbine-powered helicopters use a starter/generator system. The starter/generator is permanently coupled to the accessory gearbox. When starting the engine, electrical power from the battery is supplied to the starter/generator, which turns the engine over. Once the engine is running, the starter/generator is driven by the engine and then functions as a generator.

Current from the alternator or generator is delivered through a voltage regulator to a bus bar. The voltage regulator maintains the constant voltage required by the electrical system, by regulating the output of the alternator or generator. An over-voltage control may be incorporated to prevent excessive voltage, which may damage the electrical components. The bus bar serves to distribute the current to the various electrical components of the helicopter.

A battery is used mainly for starting the engine. In addition, it permits limited operation of electrical components, such as radios and lights, without the engine running. The battery is also a valuable source of standby or emergency electrical power in the event of alternator or generator failure.

An ammeter (or load meter) is used to monitor the electrical current within the system. The ammeter reflects current flowing to and from the battery. A charging ammeter indicates that the battery is being charged. This is normal after an engine start since the battery power used in starting is being replaced. After the battery is charged, the ammeter should stabilize near zero since the alternator or generator is supplying the electrical needs of the system.

An ammeter showing a discharge means the electrical load is exceeding the output of the alternator or generator, and the battery is helping to supply electrical power. This may mean the alternator or generator is malfunctioning, or the electrical load is excessive. An ammeter displays the load placed on the alternator or generator by the electrical equipment. The RFM (see Rotorcraft Flight Manual post) for a particular helicopter shows the normal load to expect. Loss of the alternator or generator causes the load meter to indicate zero.

Electrical switches are used to select electrical components. Power may be supplied directly to the component or to a relay, which in turn provides power to the component. Relays are used when high current and/or heavy electrical cables are required for a particular component, which may exceed the capacity of the switch. Circuit breakers or fuses are used to protect various electrical components from overload. A circuit breaker pops out when its respective component is overloaded. The circuit breaker may be reset by pushing it back in, unless a short or the overload still exists. In this case, the circuit breaker continues to pop, indicating an electrical malfunction. A fuse simply burns out when it is overloaded and needs to be replaced. Manufacturers usually provide a holder for spare fuses in the event one has to be replaced in flight. Caution lights on the instrument panel may be installed to show the malfunction of an electrical component.