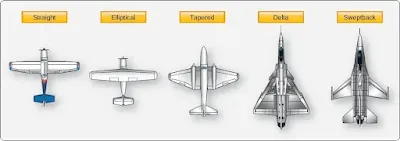

Airplanes can be designed to fly through a wide range of airspeeds. High speed flight requires smaller wing areas and moderately cambered airfoils whereas low speed flight is obtained with airfoils with a greater camber and larger wing area. [Figure 1] Many compromises are often made by designers to provide for higher speed cruise flight and low speeds for landing. Flaps are a common design effort to increase an airfoil’s camber and surface area for lower-speed flight. [Figure 2]

Since an airfoil cannot have two different cambers at the same time, designers and engineers deliver the desired performance characteristics using two different methods. Either the airfoil can be a compromise, or a cruise airfoil can be combined with a device for increasing the camber of the airfoil for low-speed flight. Camber is the asymmetry between the top and the bottom surfaces of an airfoil. One method for varying an airfoil’s camber is the addition of trailing-edge flaps. Engineers call these devices a high-lift system.

Function of Flaps

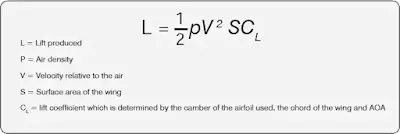

Flaps work primarily by changing the camber of the airfoil, which increases the wing’s lift coefficient. With some flap designs, the surface area of the wing is also increased. Flap deflection does not increase the critical (stall) angle of attack (AOA). In some cases, flap deflection actually decreases the critical AOA. Deflection of a wing’s control surfaces, such as ailerons and flaps, alters both lift and drag. With aileron deflection, there is asymmetrical lift which imparts a rolling moment about the airplane’s longitudinal axis. Wing flaps act symmetrically about the longitudinal axis producing no rolling moment; however, both lift and drag increase as well as a pitching moment about the lateral axis. Lift is a function of several variables including air density, velocity, surface area, and lift coefficient. Since flaps increase an airfoil’s lift coefficient, lift is increased. [Figure 3]

|

| Figure 3. Lift equation |

As flaps are deflected, the aircraft may pitch nose-up, nose-down, or have minimal changes in pitch attitude. Pitching moment is caused by the rearward movement of the wing’s center of pressure; however, that pitching behavior depends on several variables including flap type, wing position, downwash behavior, and horizontal tail location. Consequently, pitch behavior depends on the design features of the particular airplane.Flap deflection of up to 15° primarily produces lift with minimal increases in drag. Deflection beyond 15° produces a large increase in drag. Drag from flap deflection is parasite drag and, as such, is proportional to the square of the speed. Also, deflection beyond 15° produces a significant nose-up pitching moment in most high-wing airplanes because the resulting downwash changes the airflow over the horizontal tail.

Flap Effectiveness

Flap effectiveness depends on a number of factors, but the most noticeable are size and type. For the purpose of this post. trailing edge flaps are classified as four basic types: plain (hinge), split, slotted, and Fowler. [Figure 4]

|

| Figure 4. Four basic types of flaps |

The plain or hinge flap is a hinged section of the wing. The structure and function are comparable to the other control surfaces— ailerons, rudder, and elevator. The split flap is more complex. It is the lower or underside portion of the wing; deflection of the flap leaves the upper trailing edge of the wing undisturbed. It is, however, more effective than the hinge flap because of greater lift and less pitching moment, but there is more drag. Split flaps are more useful for landing, but the partially deflected hinge flaps have the advantage in takeoff. The split flap has significant drag at small deflections, whereas the hinge flap does not because airflow remains “attached” to the flap.The slotted flap has a gap between the wing and the leading edge of the flap. The slot allows high-pressure airflow on the wing undersurface to energize the lower pressure over the top, thereby delaying flow separation. The slotted flap has greater lift than the hinge flap but less than the split flap; but, because of a higher lift-drag ratio, it gives better takeoff and climb performance. Small deflections of the slotted flap give a higher drag than the hinge flap but less than the split. This allows the slotted flap to be used for takeoff.

The Fowler flap deflects down and aft to increase the wing area. This flap can be multi-slotted making it the most complex of the trailing-edge systems. This system does, however, give the maximum lift coefficient. Drag characteristics at small deflections are much like the slotted flap. Fowler flaps are most commonly used on larger airplanes because of their structural complexity and difficulty in sealing the slots.

Operational Procedures

It would be impossible to discuss all the many airplane design and flap combinations. Pilots should refer to the Federal Aviation Administration (FAA) approved Airplane Flight Manual and/or Pilot’s Operating Handbook (AFM/POH) for a given airplane.However, while some AFM/POHs are specific as to operational use of flaps, others leave the use of flaps to pilot discretion. Since flaps are often used for landings and takeoffs, when the airplane is close to the ground, pilot judgment and error avoidance are of critical importance.

Since the recommendations given in the AFM/POH are based on the airplane and the flap design, the pilot should relate the manufacturer’s recommendation to aerodynamic effects of flaps. This requires basic background knowledge of flap aerodynamics and geometry. With this information, a decision as to the degree of flap deflection and time of deflection based on runway and approach conditions relative to the wind conditions can be made.

The time of flap extension and the degree of deflection are related. Large changes in flap deflection at one single point in the landing pattern can produce large lift changes that require significant pitch and power changes in order to maintain airspeed and descent angle. Consequently, there is an advantage to extending flaps in increments while in the landing pattern. Incremental deflection of flaps on downwind, base leg, and final approach allow smaller adjustments of pitch and power and support a stabilized approach.

While normal, soft-field, or short-field landings require minimal speed at touchdown, a short-field obstacle approach requires minimum speed and a steep approach angle. Flap extension, particularly beyond 30°, results in significant levels of drag. The drag can produce a high sink rate that the pilot needs to control with power. When a pilot uses power during a steep approach or short-field approach to offset the drag produced by the flaps, the landing flare becomes critical. A reduction in power too early can result in a hard landing, airplane damage, or loss of control. A reduction in power too late causes the airplane to float down the runway.

Crosswind component is another factor to be considered in the degree of flap extension. The deflected flap presents a surface area for the wind to act on. With flaps extended in a crosswind, the wing on the upwind side is more affected than the downwind wing. The effect is reduced to a slight extent in the crabbed approach since the airplane is more nearly aligned with the wind. When using a wing-low approach, the lowered wing partially blocks the upwind flap. The dihedral of the wing combined with the flap and wind make lateral control more difficult. Lateral control becomes more difficult as flap extension reaches maximum and the crosswind becomes perpendicular to the runway.

With flaps extended, the crosswind effects on the wing become more pronounced as the airplane reaches the ground. The wing, flap, and ground on the upwind side of the airplane form a “container” that is filled with air by the crosswind. Since the flap is located behind the main landing gear, wind striking the deflected flap tends to yaw the airplane into the wind and raise the upwind wing. The raised wing reduces the tire forces and further increases the tendency to turn into the wind. Proper control position (ailerons into the wind) is essential for maintaining runway alignment. Depending on the amount of crosswind, it may be necessary to retract the flaps soon after touchdown in order to maintain control of the airplane.

The go-around is another factor to consider when making a decision about degree of flap deflection and about where in the landing pattern to extend flaps. Because of the nose-down pitching moment produced with flap extension, trim is used to offset this pitching moment. Application of full power in the go-around increases the airflow over the wing. This produces additional lift causing significant changes in pitch. The pitch-up tendency does not diminish completely with flap retraction because of the trim setting. Expedient retraction of flaps is desirable to eliminate drag; however, the pilot should be prepared for rapid changes in pitch forces as the result of trim and the increase in airflow over the control surfaces. [Figure 5]

|

| Figure 5. Flaps extended pitching moment |

During a go-around, the pilot should carefully monitor pitch and airspeed and expect that the degree of flap deflection and the design configuration of the horizontal tail relative to the wing will affect go-around characteristics. The pilot should carefully monitor pitch and airspeed, control flap retraction to minimize altitude loss, and use rudder for coordination. Considering these factors, it is good practice to extend the same degree of flaps at the same point in the landing pattern for each landing. Consistent use of flaps in the traffic pattern allows for a preplanned and familiar go-around sequence based on the airplane’s position in the landing pattern.There is no single formula to determine the degree of flap deflection to be used on landing because a landing involves variables that are dependent on each other. The AFM/POH for the particular airplane contains the manufacturer’s recommendations for some landing situations. On the other hand, AFM/POH information on flap usage for takeoff is more precise. The manufacturer’s requirements are based on the climb performance produced by a given flap design. Under no circumstances should a flap setting given in the AFM/POH be exceeded for takeoff.