Most small aircraft use a direct-cranking electric starter system. This system consists of a source of electricity, wiring, switches, and solenoids to operate the starter and a starter motor. Most aircraft have starters that automatically engage and disengage when operated, but some older aircraft have starters that are mechanically engaged by a lever actuated by the pilot. The starter engages the aircraft flywheel, rotating the engine at a speed that allows the engine to start and maintain operation.

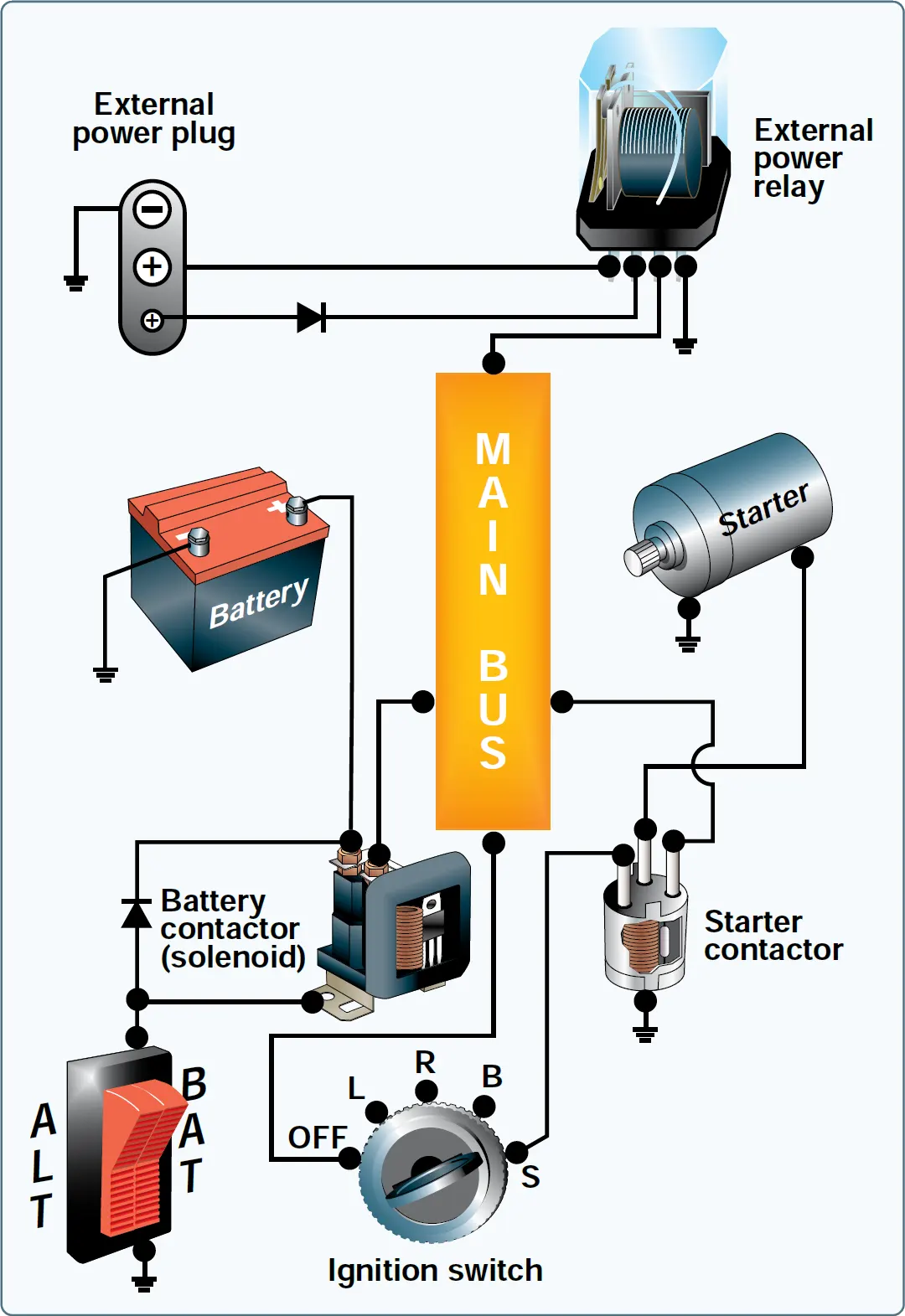

Electrical power for starting is usually supplied by an onboard battery, but can also be supplied by external power through an external power receptacle. When the battery switch is turned on, electricity is supplied to the main power bus bar through the battery solenoid. Both the starter and the starter switch draw current from the main bus bar, but the starter will not operate until the starting solenoid is energized by the starter switch being turned to the “start” position. When the starter switch is released from the “start” position, the solenoid removes power from the starter motor. The starter motor is protected from being driven by the engine through a clutch in the starter drive that allows the engine to run faster than the starter motor. [Figure]

When starting an engine, the rules of safety and courtesy should be strictly observed. One of the most important safety rules is to ensure there is no one near the propeller prior to starting the engine. In addition, the wheels should be chocked and the brakes set to avoid hazards caused by unintentional movement. To avoid damage to the propeller and property, the aircraft should be in an area where the propeller will not stir up gravel or dust.