Jet airplanes have high kinetic energy during the landing roll because of weight and speed. This energy is difficult to dissipate because a jet airplane has low drag with the nose-wheel on the ground, and the engines continue to produce forward thrust with the power levers at idle. While wheel brakes serve as the primary means to stop the airplane, reverse thrust, when available, assists in deceleration.

Certain thrust reverser designs effectively reverse the flow of the exhaust gases. The flow does not completely reverse. Typically, the final path of the exhaust gases is about 45° from straight ahead. This, together with the losses from the flow paths, reduces reverse thrust efficiency. If the pilot uses less than maximum rpm in reverse, the reverse thrust is further reduced.

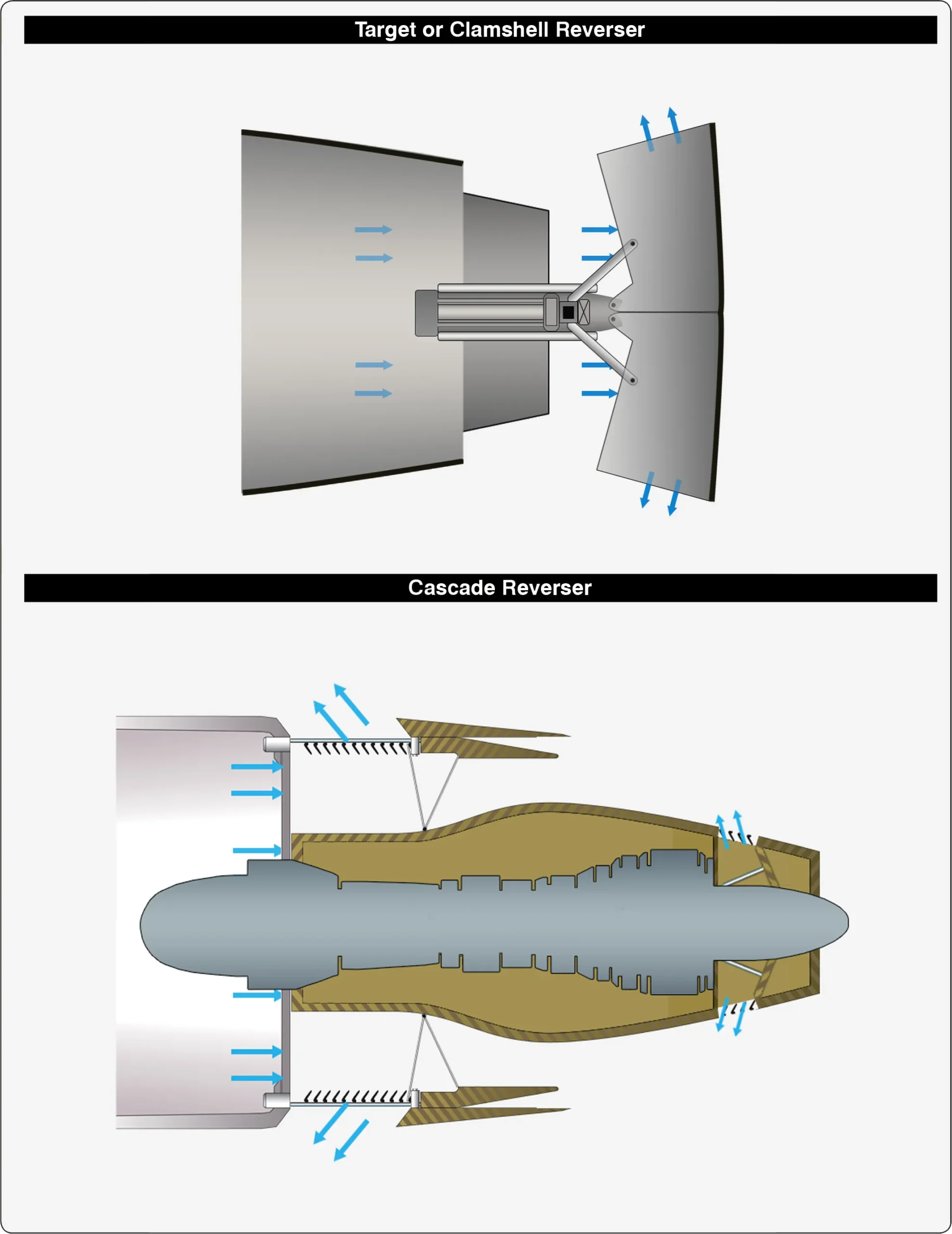

Normally, a jet engine has one of two types of thrust reversers: a target reverser or a cascade reverser. [Figure] Target reversers are simple clamshell doors that swivel from the stowed position at the engine tailpipe to redirect thrust to a more forward direction.

Cascade reversers are normally found on turbofan engines and are often designed to reverse only the fan air portion. Blocking doors in the shroud obstruct forward fan thrust and redirect it through cascade vanes to generate reverse thrust.

On most installations, the pilot selects reverse thrust with the thrust levers at idle by pulling up the reverse levers to a detent. Doing so positions the reversing mechanisms for operation but leaves the engines at idle rpm. Further upward and backward movement of the reverse levers increases engine power. Reverse is canceled by closing the reverse levers to the idle reverse position, then dropping them fully back to the forward idle position. This last movement selects the stowed position, and the reversers return to the forward thrust position.

Reverse thrust is more effective at high speed than at low speed. For maximum reverse thrust efficiency, the pilot should use it as soon as is prudent after touchdown. The pilot should remember that some airplanes tend to pitch nose-up when reverse is selected on landing and this effect, particularly when combined with the nose-up pitch effect from the spoilers, can cause the airplane to leave the ground again momentarily. On these types, the airplane should be firmly on the ground with the nose-wheel down before reverse is selected. Other types of airplanes have no change in pitch, and reverse idle may be selected after the main gear is down and before the nose-wheel is down. Since reverse thrust may affect directional control, runway surface conditions (e.g., contamination), factor into the use of reverse thrust. Specific procedures for reverse thrust operation for a particular airplane/engine combination are contained in the FAA-approved AFM for that airplane.

There is a significant difference between reverse pitch on a propeller and reverse thrust from a jet engine. Idle reverse on a propeller produces a large amount of drag. On a jet engine, however, selecting idle reverse produces very little reverse thrust. In a jet airplane, the pilot should select reverse, apply reverse thrust as appropriate, and remain within any AFM limitations.

It is essential that pilots understand not only the normal procedures and limitations of thrust reverser use, but also the procedures for coping with uncommanded reverse. While thrust reverser systems are designed to prevent unintentional deployment, an uncommanded or inadvertent deployment of thrust reversers, while airborne, is an emergency. The systems normally contain several lock systems: one to keep reversers from operating in the air, another to prevent operation with the thrust levers out of the idle detent, and/or an “auto-stow” circuit to command reverser stowage any time thrust reverser deployment would be inappropriate, such as during takeoff and while airborne.