The helicopter rotor system is the rotating part of a helicopter that generates lift. A rotor system may be mounted horizontally, as main rotors are, providing lift vertically; and it may be mounted vertically, such as a tail rotor, to provide lift horizontally as thrust to counteract torque effect. In the case of tilt rotors, the rotor is mounted on a nacelle that rotates at the edge of the wing to transition the rotor from a horizontal mounted position, providing lift horizontally as thrust, to a vertical mounted position providing lift exactly as a helicopter.

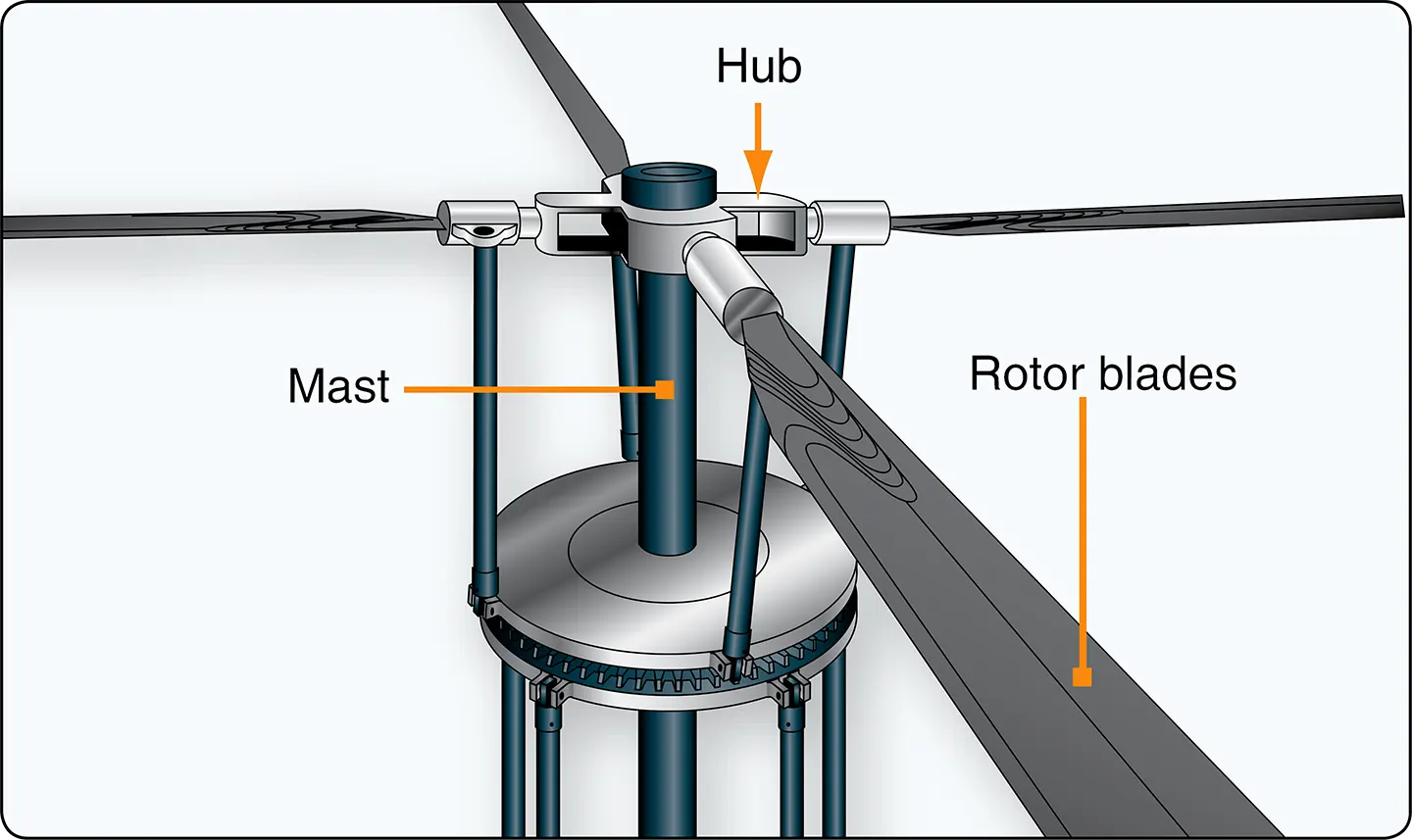

The rotor consists of a mast, hub, and rotor blades. [Figure 1]

The mast is a hollow cylindrical metal shaft which extends upwards from and is driven by the transmission. At the top of the mast is the attachment point for the rotor blades called the hub. The rotor blades are then attached to the hub by several different methods. Main rotor systems are classified according to how the main rotor blades are attached and move relative to the main rotor hub. There are three basic classifications: semirigid, rigid, or fully articulated, although some modern rotor systems use an engineered combination of these types. All three rotor systems are discussed with greater detail in Helicopter Components, Sections, and Systems section.

With a single main rotor helicopter, a torque effect is created as the engine turns the rotor. This torque causes the body of the helicopter to turn in the opposite direction of the rotor (Newton’s Third Law: Every action has an equal and opposite reaction, as explained in Aerodynamics of Flight section).

To eliminate this effect, some sort of antitorque control must be used with a sufficient margin of power available to allow the helicopter to maintain its heading and prevent the aircraft from moving unsteadily. The three most common controls used today are the traditional tail rotor, Fenestron (also called a fantail), and the NOTAR®. All three antitorque designs will be discussed in Helicopter Components, Sections, and Systems section.

Rotor Configurations

Most helicopters have a single, main rotor but require a separate rotor to overcome torque which is a turning or twisting force. This is accomplished through a variable pitch, antitorque rotor or tail rotor. This is the design that Igor Sikorsky settled on for his VS-300 helicopter shown in Figure 2.

It has become the recognized convention for helicopter design, although designs do vary. Helicopter main rotor designs from different manufacturers rotate in one of two different directions (clockwise or counter-clockwise when viewed from above). This can make it confusing when discussing aerodynamic effects on the main rotor between different designs, since the effects may manifest on opposite sides of each aircraft.

For clarity, throughout this site, all examples use a counter-clockwise rotating main rotor system when viewed from above.

Tandem Rotor

Tandem rotor (sometimes referred to as dual rotor) helicopters have two large horizontal rotor assemblies, instead of one main assembly and a smaller tail rotor. [Figure 3]

Single rotor helicopters need a tail rotor to neutralize the twisting momentum produced by the single large rotor. Tandem rotor helicopters, however, use counter-rotating rotors, each canceling out the other’s torque. Counter-rotating rotor blades will not collide with and destroy each other if they flex into the other rotor’s pathway. This configuration has the advantage of being able to hold more weight with shorter blades, since there are two blade sets. Also, all the power from the engines can be used for lift, whereas a single rotor helicopter must use some power to counter main rotor torque. Because of this, tandem helicopters make up some of the most powerful and fastest rotor system aircraft.

Coaxial Rotors

Coaxial rotors are a pair of rotors turning in opposite directions, but mounted on a mast, with the same axis of rotation, one above the other. This configuration is a noted feature of helicopters produced by the Russian Kamov helicopter design bureau. [Figure 4]

Intermeshing Rotors

Intermeshing rotors on a helicopter are a set of two rotors turning in opposite directions, with each rotor mast mounted on the helicopter with a slight angle to the other so that the blades intermesh without colliding. [Figure 5]

This arrangement allows the helicopter to function without the need for a tail rotor. It has high stability and powerful lifting capability. This configuration is sometimes referred to as a synchropter. The arrangement was developed in Germany for a small anti-submarine warfare helicopter, the Flettner Fl 282 Kolibri. During the Cold War the American Kaman Aircraft company produced the HH-43 Huskie, for USAF firefighting purposes. The latest Kaman K-MAX model is a dedicated sky crane design used for construction work.

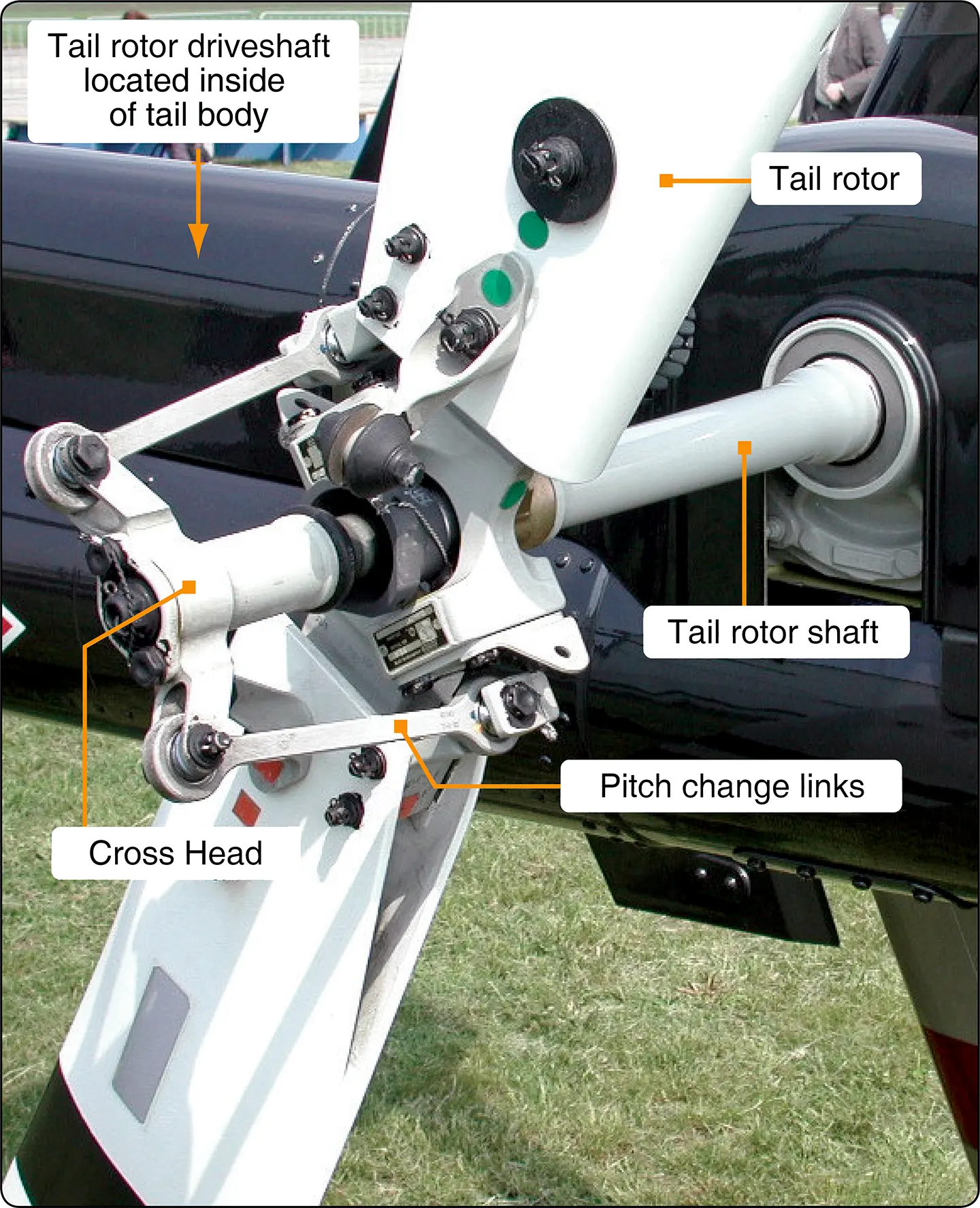

Tail Rotor

The tail rotor is a smaller rotor mounted vertically or near-vertically on the tail of a traditional single-rotor helicopter. The tail rotor either pushes or pulls against the tail to counter the torque. The tail rotor drive system consists of a drive shaft powered from the main transmission and a gearbox mounted at the end of the tail boom. [Figure 6] The drive shaft may consist of one long shaft or a series of shorter shafts connected at both ends with flexible couplings. The flexible couplings allow the drive shaft to flex with the tail boom.

The gearbox at the end of the tail boom provides an angled drive for the tail rotor and may also include gearing to adjust the output to the optimum rotational speed typically measured in revolutions per minute (rpm) for the tail rotor. On some larger helicopters, intermediate gearboxes are used to angle the tail rotor drive shaft from along the tail boom or tailcone to the top of the tail rotor pylon, which also serves as a vertical stabilizing airfoil to alleviate the power requirement for the tail rotor in forward flight. The pylon (or vertical fin) may also provide limited antitorque within certain airspeed ranges if the tail rotor or the tail rotor flight controls fail.