Reciprocating Engines

Reciprocating engines, also called piston engines, are generally used in smaller helicopters. Most training helicopters use reciprocating engines because they are relatively simple and inexpensive to operate.

Turbine Engines

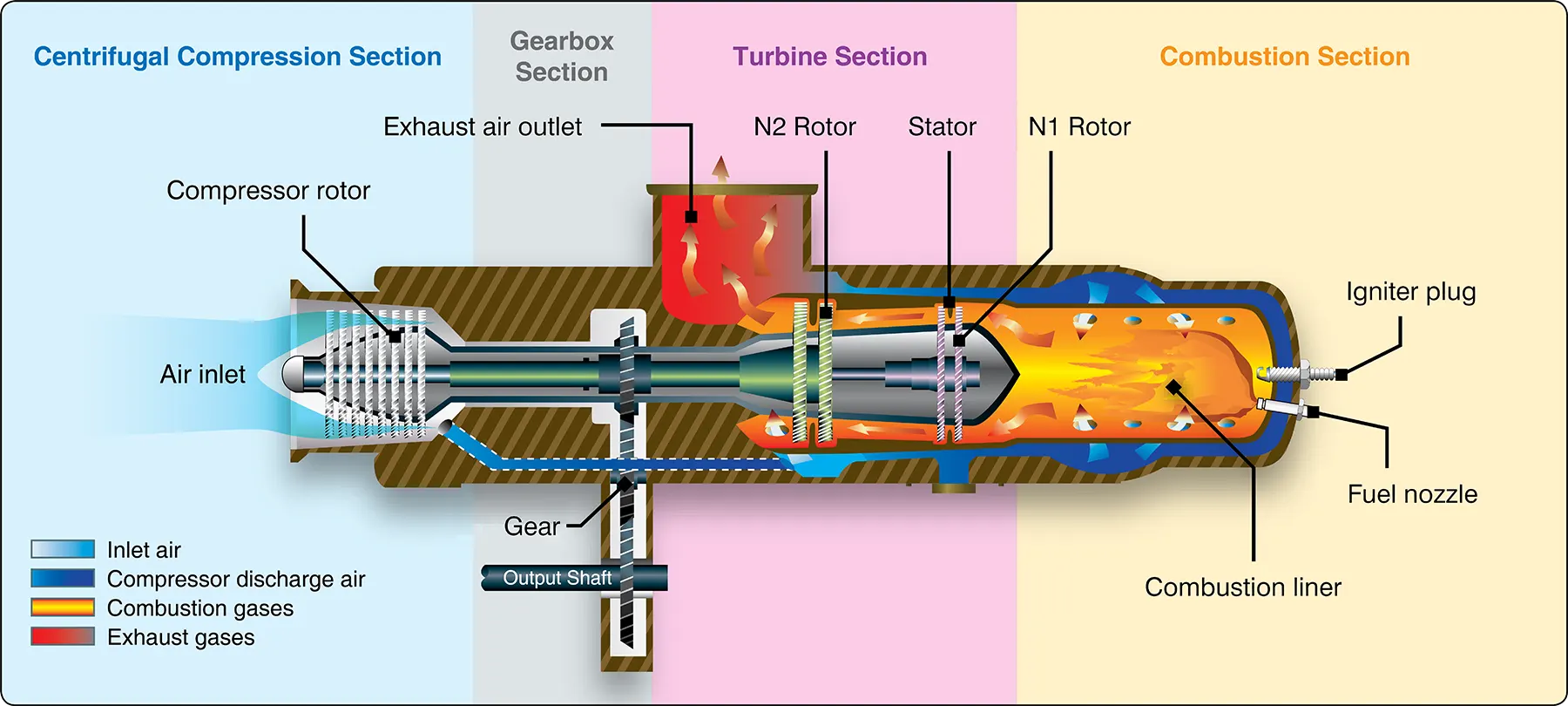

Turbine engines are more powerful and are used in a wide variety of helicopters. They produce a tremendous amount of power for their size but are generally more expensive to operate. The turbine engine used in helicopters operates differently from those used in airplane applications. In most applications, the exhaust outlets simply release expended gases and do not contribute to the forward motion of the helicopter. Approximately 75 percent of the incoming airflow is used to cool the engine.

The gas turbine engine mounted on most helicopters is made up of a compressor, combustion chamber, turbine, and accessory gearbox assembly. The compressor draws filtered air into the plenum chamber and compresses it. Common type filters are centrifugal swirl tubes where debris is ejected outward and blown overboard prior to entering the compressor, or engine barrier filters (EBF), similar to the K&N filter element used in automotive applications.

Although this design significantly reduces the ingestion of FOD, it is important for pilots to be aware of how much debris is actually being filtered. Operating in the sand, dust, or even in grassy type materials can choke an engine in just minutes. The compressed air is directed to the combustion section through discharge tubes where atomized fuel is injected into it. The fuel/air mixture is ignited and allowed to expand. This combustion gas is then forced through a series of turbine wheels causing them to turn. These turbine wheels provide power to both the engine compressor and the accessory gearbox. Depending on model and manufacturer, the rpm range can vary from a range low of 20,000 to a range high of 51,600.

Power is provided to the main rotor and tail rotor systems through the freewheeling unit which is attached to the accessory gearbox power output gear shaft. The combustion gas is finally expelled through an exhaust outlet. The temperature of gas is measured at different locations and is referenced differently by each manufacturer. Some common terms are: inter-turbine temperature (ITT), exhaust gas temperature (EGT), or turbine outlet temperature (TOT). TOT is used throughout this discussion for simplicity purposes. [Figure]

Compressor

The compressor may consist of an axial compressor, a centrifugal compressor, or combination of the two.

An axial compressor consists of two main elements: the rotor and the stator. The rotor consists of a number of blades fixed on a rotating spindle and resembles a fan. As the rotor turns, air is drawn inward. Stator vanes are arranged in fixed rows between the rotor blades and act as a diffuser at each stage to decrease air velocity and increase air pressure. There may be a number of rows of rotor blades and stator vanes. Each row constitutes a pressure stage, and the number of stages depends on the amount of air and pressure rise required for the particular engine.

A centrifugal compressor consists of an impeller, diffuser, and a manifold. The impeller, which is a forged disc with integral blades, rotates at a high speed to draw air in and expel it at an accelerated rate. The air then passes through the diffuser, which slows the air down. When the velocity of the air is slowed, static pressure increases, resulting in compressed, high pressure air. The high pressure air then passes through the compressor manifold where it is distributed to the combustion chamber via discharge tubes.

If the airflow through the compressor is disturbed, a condition called surge, or compressor stall, may take effect. This phenomenon is a periodic stalling of the compressor blades. When this occurs, the pressure at the compressor is reduced and the combustion pressure may cause reverse flow into the compressor output. As the airflow through the compressor is reduced, the air pressure then increases temporarily correcting the condition until it occurs again. This is felt throughout the airframe as vibrations and is accompanied by power loss and an increase in turbine outlet temperature (TOT) as the fuel control adds fuel in an attempt to maintain power. This condition may be corrected by activating the bleed air system which vents excess pressure to the atmosphere and allows a larger volume of air to enter the compressor to unstall the compressor blades.

Combustion Chamber

Unlike a piston engine, the combustion in a turbine engine is continuous. An igniter plug serves only to ignite the fuel/air mixture when starting the engine. Once the fuel/air mixture is ignited, it continues to burn as long as the fuel/air mixture continues to be present. If there is an interruption of fuel, air, or both, combustion ceases. This is known as a “flameout,” and the engine must be restarted or re-lit. Some helicopters are equipped with auto-relight, which automatically activates the igniters to start combustion if the engine flames out.

Turbine

The two-stage turbine section consists of a series of turbine wheels that are used to drive the compressor section and other components attached to the accessory gearbox. Both stages may consist of one or more turbine wheels. The first stage is usually referred to as the gas producer (N1 or NG) while the second stage is commonly called the power turbine (N2 or NP). (The letter N is used to denote rotational speed.)

If the first and second stage turbines are mechanically coupled to each other, the system is said to be a direct-drive engine or fixed turbine. These engines share a common shaft, which means the first and second stage turbines, and thus the compressor and output shaft, are connected.

On most turbine assemblies used in helicopters, the first stage and second stage turbines are not mechanically connected to each other. Rather, they are mounted on independent shafts, one inside the other, and can turn freely with respect to each other. This is referred to as a “free turbine.” When the engine is running, the combustion gases pass through the first stage turbine (N1) to drive the compressor and other components, and then past the independent second stage turbine (N2), which turns the power and accessory gearbox to drive the output shaft, as well as other miscellaneous components.

Accessory Gearbox

The accessory gearbox of the engine houses all of the necessary gears to drive the numerous components of the helicopter. Power is provided to the accessory gearbox through the independent shafts connected to the N1 and N2 turbine wheels. The N1 stage drives the components necessary to complete the turbine cycle, making the engine self-sustaining. Common components driven by the N1 stage are the compressor, oil pump, fuel pump, and starter/ generator. The N2 stage is dedicated to driving the main rotor and tail rotor drive systems and other accessories such as generators, alternators, and air conditioning.