Several flight instruments utilize the properties of a gyroscope for their operation. The most common instruments containing gyroscopes are the turn coordinator, heading indicator, and the attitude indicator. To understand how these instruments operate requires knowledge of the instrument power systems, gyroscopic principles, and the operating principles of each instrument.

Gyroscopic Principles

Any spinning object exhibits gyroscopic properties. A wheel or rotor designed and mounted to utilize these properties is called a gyroscope. Two important design characteristics of an instrument gyro are great weight for its size, or high density, and rotation at high speed with low friction bearings.

There are two general types of mountings; the type used depends upon which property of the gyro is utilized. A freely or universally mounted gyroscope is free to rotate in any direction about its center of gravity. Such a wheel is said to have three planes of freedom. The wheel or rotor is free to rotate in any plane in relation to the base and is balanced so that, with the gyro wheel at rest, it remains in the position in which it is placed. Restricted or semi-rigidly mounted gyroscopes are those mounted so that one of the planes of freedom is held fixed in relation to the base.

There are two fundamental properties of gyroscopic action: rigidity in space and precession.

Rigidity in Space

Rigidity in space refers to the principle that a gyroscope remains in a fixed position in the plane in which it is spinning. An example of rigidity in space is that of a bicycle wheel. As the bicycle wheels increase speed, they become more stable in their plane of rotation. This is why a bicycle is unstable and maneuverable at low speeds and stable and less maneuverable at higher speeds.

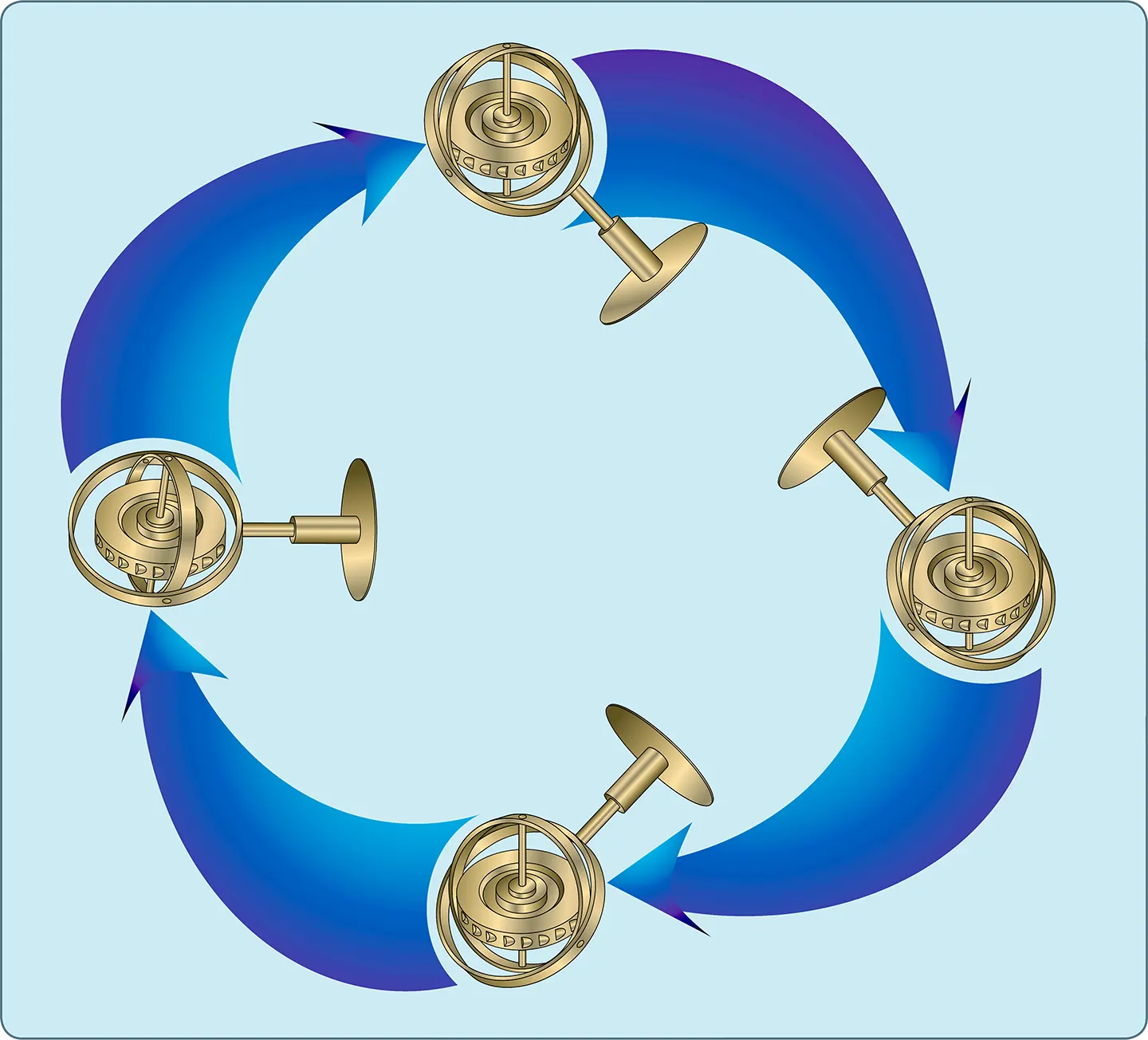

By mounting this wheel, or gyroscope, on a set of gimbal rings, the gyro is able to rotate freely in any direction. Thus, if the gimbal rings are tilted, twisted, or otherwise moved, the gyro remains in the plane in which it was originally spinning. [Figure 1]

Precession

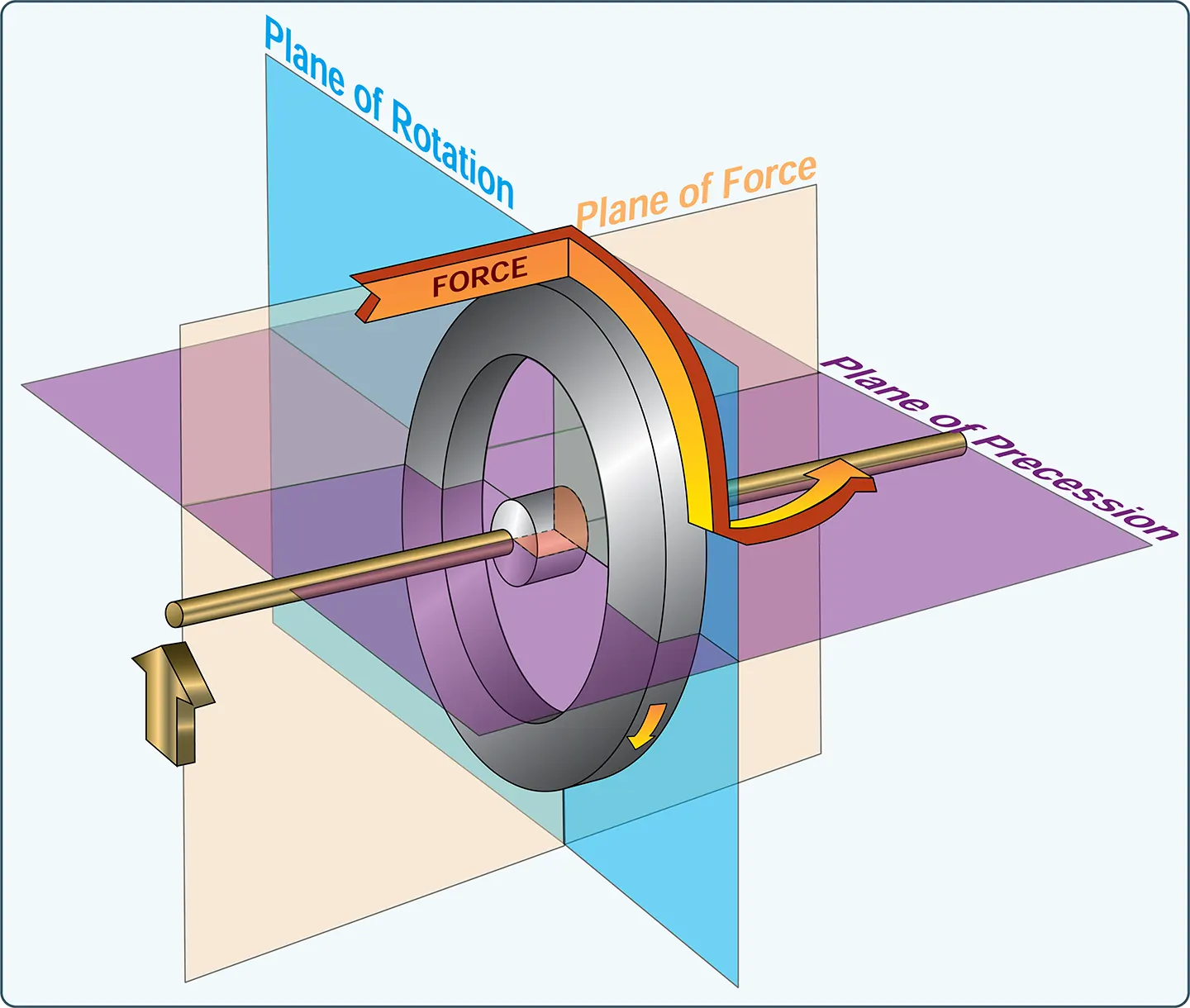

Precession is the tilting or turning of a gyro in response to a deflective force. The reaction to this force does not occur at the point at which it was applied; rather, it occurs at a point that is 90° later in the direction of rotation. This principle allows the gyro to determine a rate of turn by sensing the amount of pressure created by a change in direction. The rate at which the gyro precesses is inversely proportional to the speed of the rotor and proportional to the deflective force.

Using the example of the bicycle, precession acts on the wheels in order to allow the bicycle to turn. While riding at normal speed, it is not necessary to turn the handle bars in the direction of the desired turn. A rider simply leans in the direction that he or she wishes to go. Since the wheels are rotating in a clockwise direction when viewed from the right side of the bicycle, if a rider leans to the left, a force is applied to the top of the wheel to the left. The force actually acts 90° in the direction of rotation, which has the effect of applying a force to the front of the tire, causing the bicycle to move to the left. There is a need to turn the handlebars at low speeds because of the instability of the slowly turning gyros and also to increase the rate of turn.

Precession can also create some minor errors in some instruments. [Figure 2] Precession can cause a freely spinning gyro to become displaced from its intended plane of rotation through bearing friction, etc. Certain instruments may require corrective realignment during flight, such as the heading indicator.

Sources of Power

In some aircraft, all the gyros are vacuum, pressure, or electrically operated. In other aircraft, vacuum or pressure systems provide the power for the heading and attitude indicators, while the electrical system provides the power for the turn coordinator. Most aircraft have at least two sources of power to ensure at least one source of bank information is available if one power source fails. The vacuum or pressure system spins the gyro by drawing a stream of air against the rotor vanes to spin the rotor at high speed, much like the operation of a waterwheel or turbine. The amount of vacuum or pressure required for instrument operation varies, but is usually between 4.5 “Hg and 5.5 “Hg.

One source of vacuum for the gyros is a vane-type engine-driven pump that is mounted on the accessory case of the engine. Pump capacity varies in different aircraft, depending on the number of gyros.

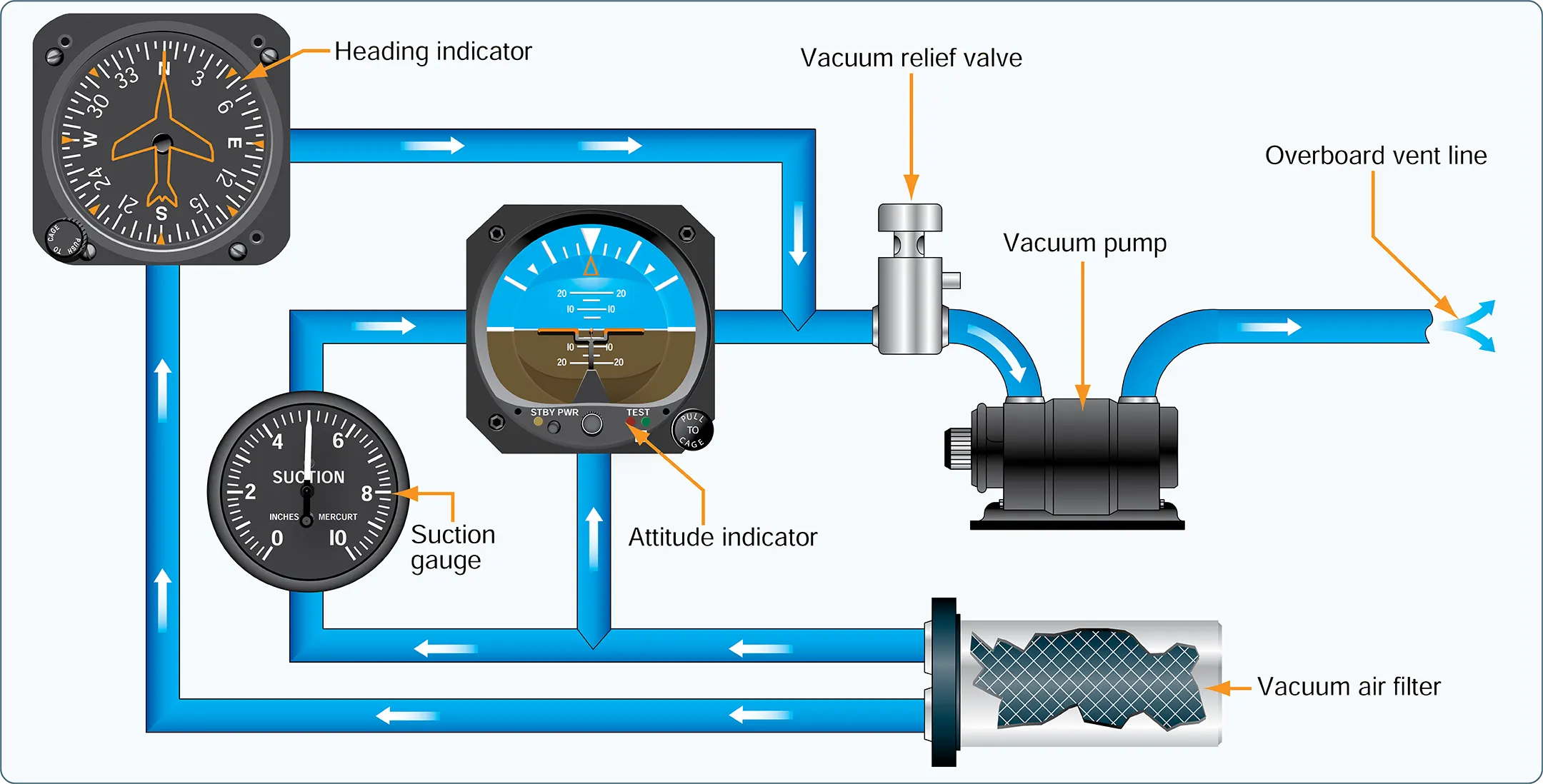

A typical vacuum system consists of an engine-driven vacuum pump, relief valve, air filter, gauge, and tubing necessary to complete the connections. The gauge is mounted in the aircraft’s instrument panel and indicates the amount of pressure in the system (vacuum is measured in inches of mercury less than ambient pressure).

As shown in Figure 3, air is drawn into the vacuum system by the engine-driven vacuum pump. It first goes through a filter, which prevents foreign matter from entering the vacuum or pressure system. The air then moves through the attitude and heading indicators where it causes the gyros to spin. A relief valve prevents the vacuum pressure, or suction, from exceeding prescribed limits. After that, the air is expelled overboard or used in other systems, such as for inflating pneumatic deicing boots.

It is important to monitor vacuum pressure during flight, because the attitude and heading indicators may not provide reliable information when suction pressure is low. The vacuum, or suction, gauge is generally marked to indicate the normal range. Some aircraft are equipped with a warning light that illuminates when the vacuum pressure drops below the acceptable level.

When the vacuum pressure drops below the normal operating range, the gyroscopic instruments may become unstable and inaccurate. Cross-checking the instruments routinely is a good habit to develop.

Turn Indicators

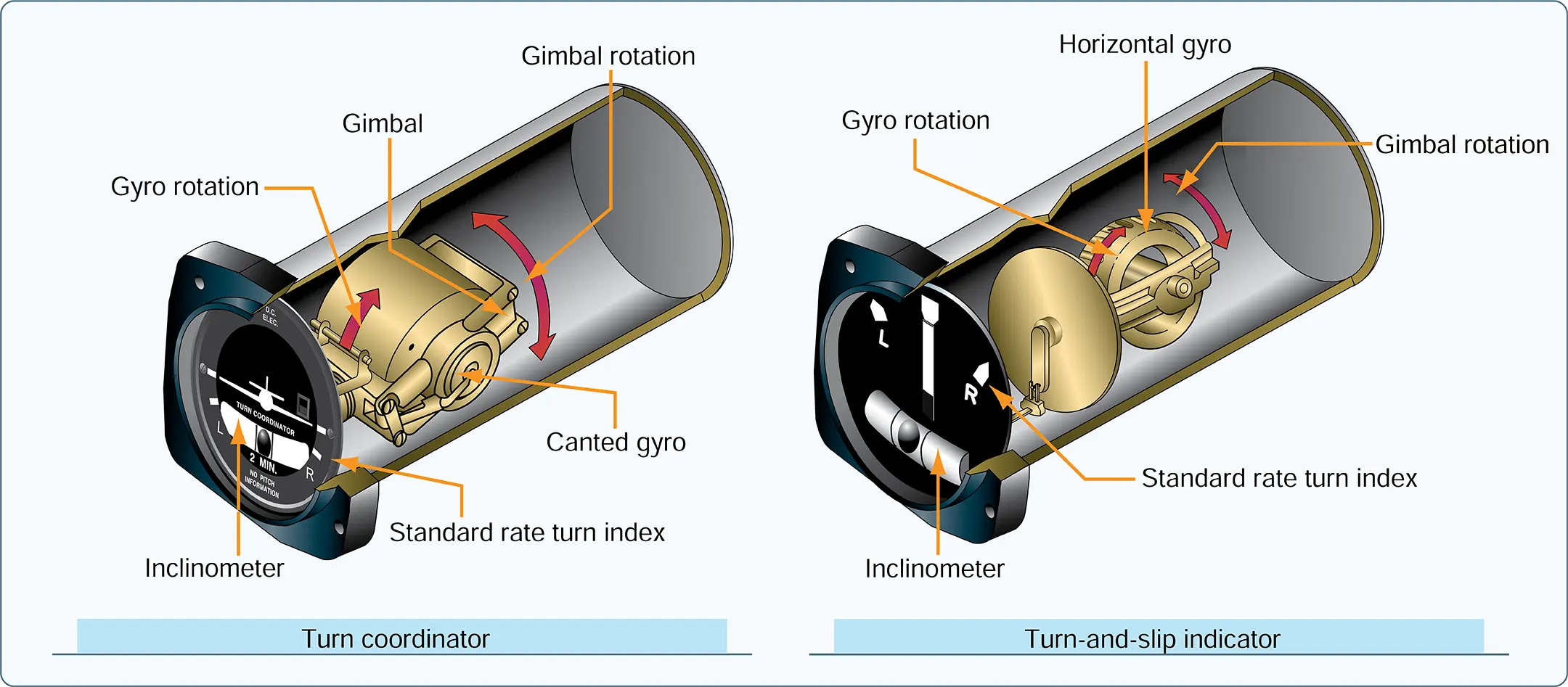

Aircraft use two types of turn indicators: turn-and-slip indicators and turn coordinators. Because of the way the gyro is mounted, the turn-and-slip indicator shows only the rate of turn in degrees per second. The turn coordinator is mounted at an angle, or canted, so it can initially show roll rate. When the roll stabilizes, it indicates rate of turn. Both instruments indicate turn direction and quality (coordination), and also serve as a backup source of bank information in the event an attitude indicator fails. Coordination is achieved by referring to the inclinometer, which consists of a liquid-filled curved tube with a ball inside. [Figure 4]

Turn-and-Slip Indicator

The gyro in the turn-and-slip indicator rotates in the vertical plane corresponding to the aircraft’s longitudinal axis. A single gimbal limits the planes in which the gyro can tilt, and a spring works to maintain a center position. Because of precession, a yawing force causes the gyro to tilt left or right, as viewed from the pilot seat. The turn-and-slip indicator uses a pointer, called the turn needle, to show the direction and rate of turn. The turn-and-slip indicator is incapable of “tumbling” off its rotational axis because of the restraining springs. When extreme forces are applied to a gyro, the gyro is displaced from its normal plane of rotation, rendering its indications invalid. Certain instruments have specific pitch and bank limits that induce a tumble of the gyro.

Turn Coordinator

The gimbal in the turn coordinator is canted; therefore, its gyro can sense both rate of roll and rate of turn. Since turn coordinators are more prevalent in training aircraft, this discussion concentrates on that instrument. When rolling into or out of a turn, the miniature aircraft banks in the direction the aircraft is rolled. A rapid roll rate causes the miniature aircraft to bank more steeply than a slow roll rate.

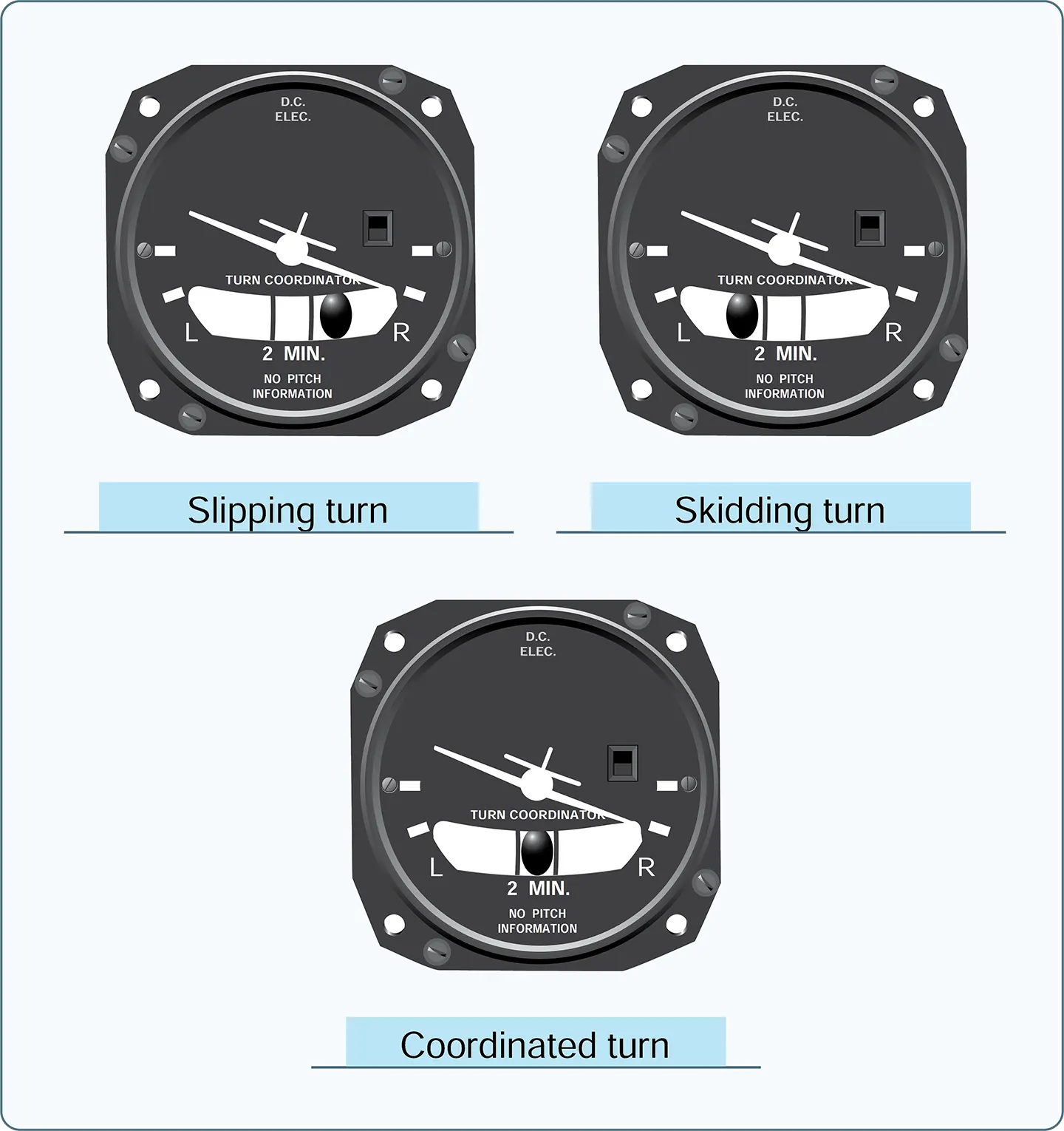

The turn coordinator can be used to establish and maintain a standard-rate turn by aligning the wing of the miniature aircraft with the turn index. Figure 5 shows a picture of a turn coordinator. There are two marks on each side (left and right) of the face of the instrument. The first mark is used to reference a wings level zero rate of turn. The second mark on the left and right side of the instrument serve to indicate a standard rate of turn. A standard-rate turn is defined as a turn rate of 3° per second. The turn coordinator indicates only the rate and direction of turn; it does not display a specific angle of bank.

Inclinometer

The inclinometer is used to depict aircraft yaw, which is the side-to-side movement of the aircraft’s nose. During coordinated, straight-and-level flight, the force of gravity causes the ball to rest in the lowest part of the tube, centered between the reference lines. Coordinated flight is maintained by keeping the ball centered. If the ball is not centered, it can be centered by using the rudder.

To center the ball, apply rudder pressure on the side to which the ball is deflected. Use the simple rule, “step on the ball,” to remember which rudder pedal to press. If aileron and rudder are coordinated during a turn, the ball remains centered in the tube. If aerodynamic forces are unbalanced, the ball moves away from the center of the tube. As shown in Figure 5, in a slip, the rate of turn is too slow for the angle of bank, and the ball moves to the inside of the turn. In a skid, the rate of turn is too great for the angle of bank, and the ball moves to the outside of the turn. To correct for these conditions, and improve the quality of the turn, remember to “step on the ball.” Varying the angle of bank can also help restore coordinated flight from a slip or skid. To correct for a slip, decrease bank and/or increase the rate of turn. To correct for a skid, increase the bank and/or decrease the rate of turn.

Yaw String

One additional tool that can be added to the aircraft is a yaw string. A yaw string is simply a string or piece of yarn attached to the center of the wind screen. When in coordinated flight, the string trails straight back over the top of the wind screen. When the aircraft is either slipping or skidding, the yaw string moves to the right or left depending on the direction of slip or skid.

Instrument Check

During preflight, ensure that the inclinometer is full of fluid and has no air bubbles. The ball should also be resting at its lowest point. When taxiing, the turn coordinator should indicate a turn in the correct direction while the ball moves opposite the direction of the turn.

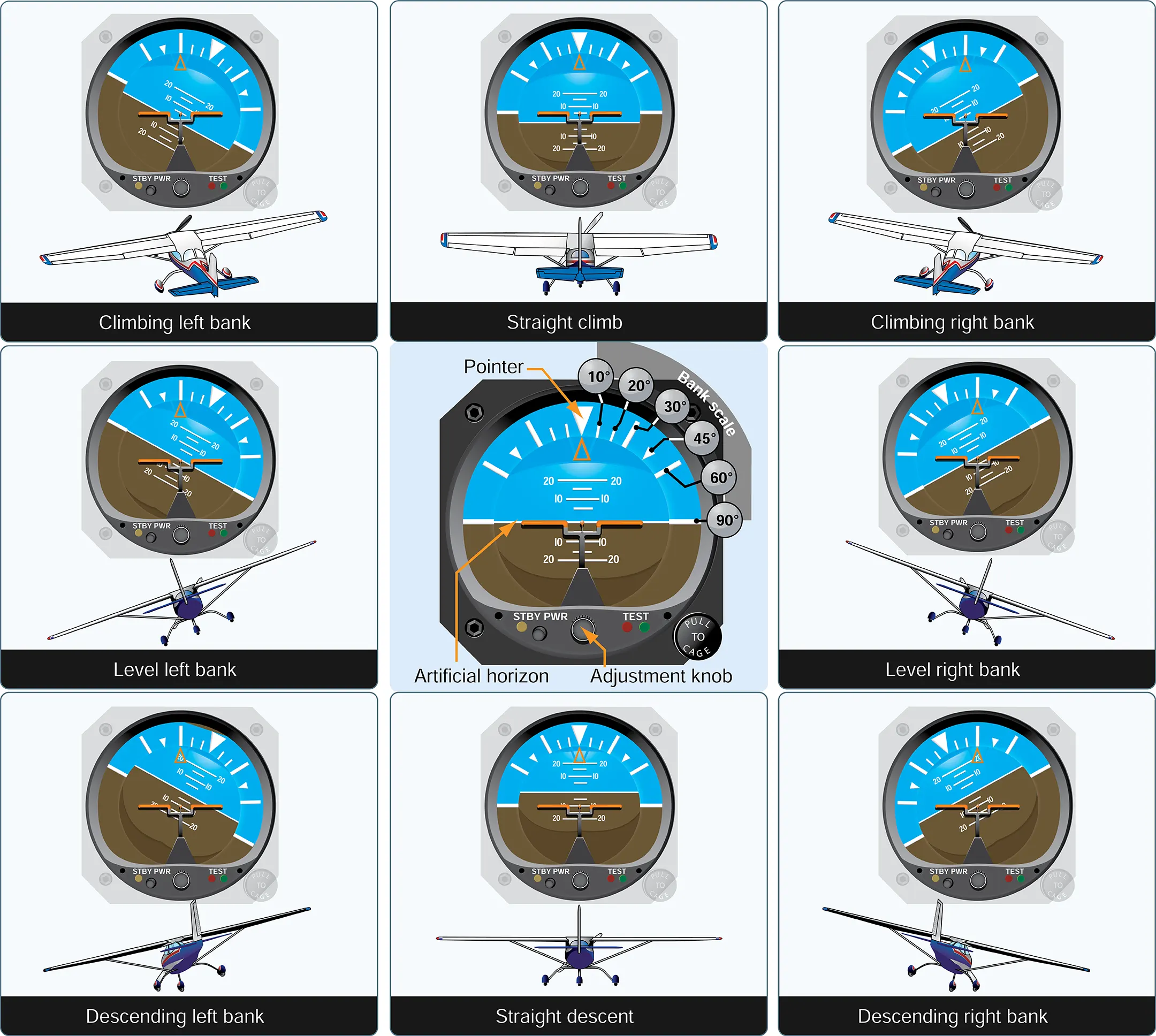

Attitude Indicator

The attitude indicator, with its miniature aircraft and horizon bar, displays a picture of the attitude of the aircraft. The relationship of the miniature aircraft to the horizon bar is the same as the relationship of the real aircraft to the actual horizon. The instrument gives an instantaneous indication of even the smallest changes in attitude.

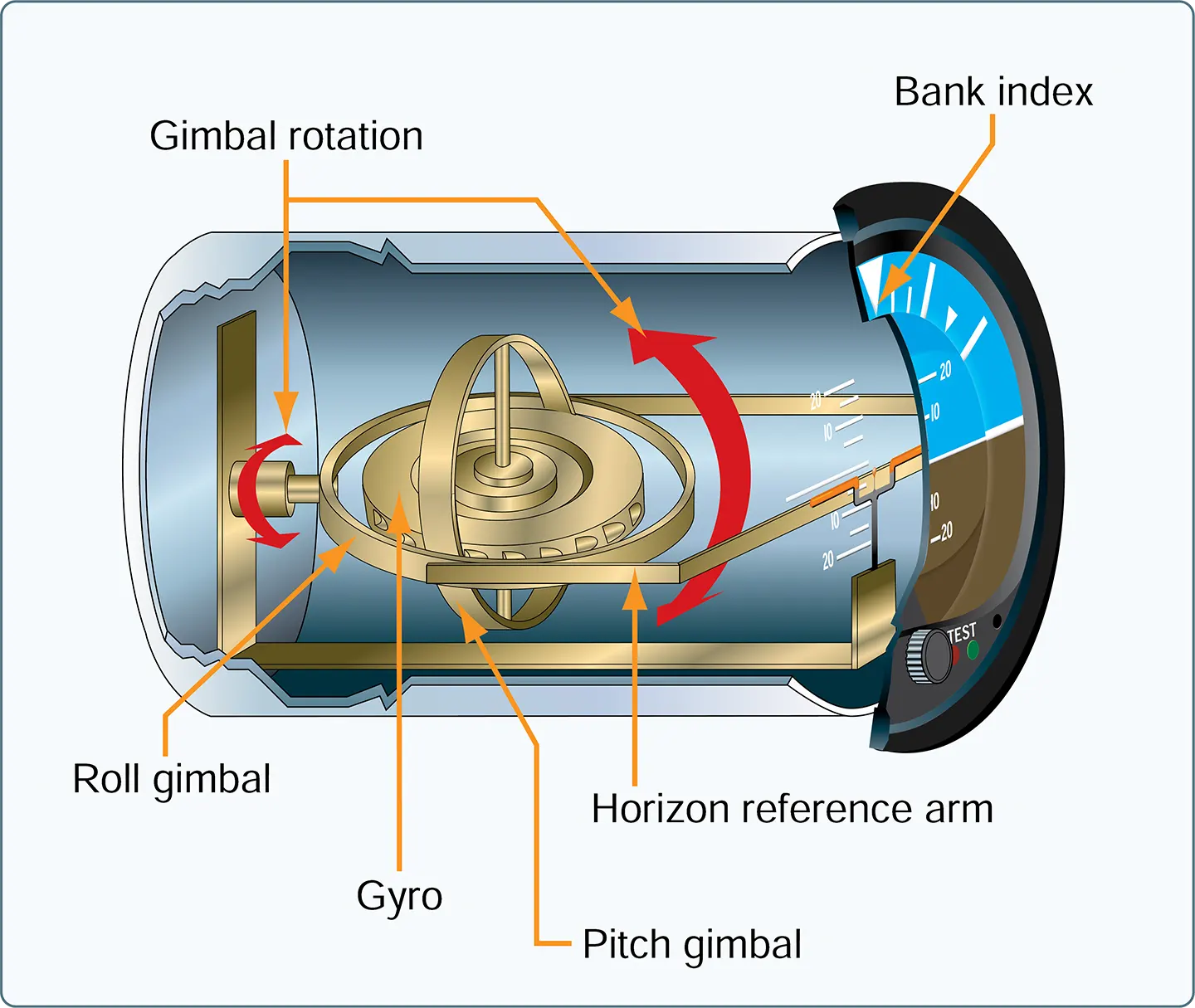

The gyro in the attitude indicator is mounted in a horizontal plane and depends upon rigidity in space for its operation. The horizon bar represents the true horizon. This bar is fixed to the gyro and remains in a horizontal plane as the aircraft is pitched or banked about its lateral or longitudinal axis, indicating the attitude of the aircraft relative to the true horizon. [Figure 6]

The gyro spins in the horizontal plane and resists deflection of the rotational path. Since the gyro relies on rigidity in space, the aircraft actually rotates around the spinning gyro.

An adjustment knob is provided with which the pilot may move the miniature aircraft up or down to align the miniature aircraft with the horizon bar to suit the pilot’s line of vision. Normally, the miniature aircraft is adjusted so that the wings overlap the horizon bar when the aircraft is in straight-and-level cruising flight.

The pitch and bank limits depend upon the make and model of the instrument. Limits in the banking plane are usually from 100° to 110°, and the pitch limits are usually from 60° to 70°. If either limit is exceeded, the instrument will tumble or spill and will give incorrect indications until realigned. A number of modern attitude indicators do not tumble.

Every pilot should be able to interpret the banking scale illustrated in Figure 7. Most banking scale indicators on the top of the instrument move in the same direction from that in which the aircraft is actually banked. Some other models move in the opposite direction from that in which the aircraft is actually banked. This may confuse the pilot if the indicator is used to determine the direction of bank. This scale should be used only to control the degree of desired bank. The relationship of the miniature aircraft to the horizon bar should be used for an indication of the direction of bank.

The attitude indicator is reliable and the most realistic flight instrument on the instrument panel. Its indications are very close approximations of the actual attitude of the aircraft.

Heading Indicator

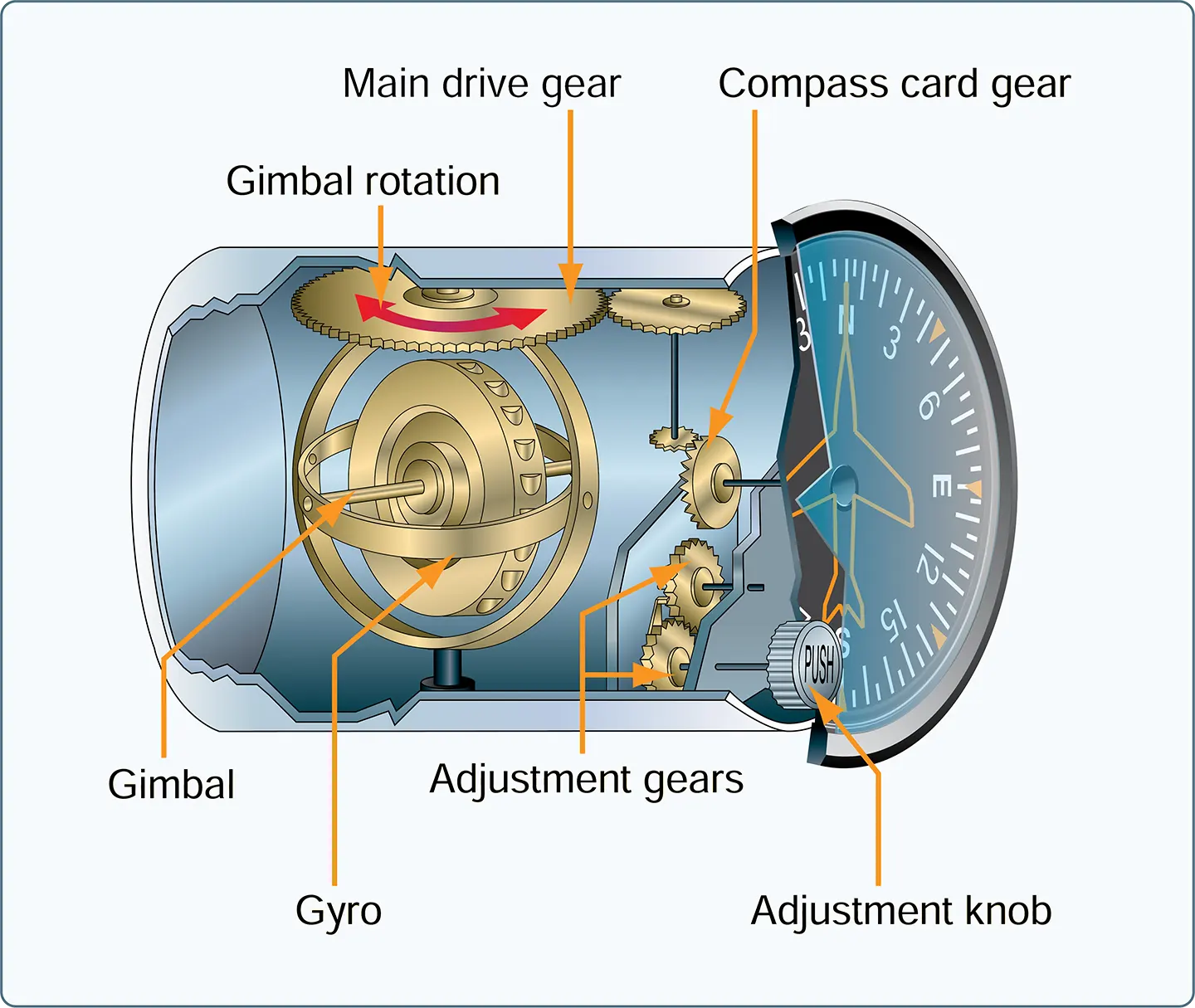

The heading indicator is fundamentally a mechanical instrument designed to facilitate the use of the magnetic compass. Errors in the magnetic compass are numerous, making straight flight and precision turns to headings difficult to accomplish, particularly in turbulent air. A heading indicator, however, is not affected by the forces that make the magnetic compass difficult to interpret. [Figure 8]

The operation of the heading indicator depends upon the principle of rigidity in space. The rotor turns in a vertical plane and fixed to the rotor is a compass card. Since the rotor remains rigid in space, the points on the card hold the same position in space relative to the vertical plane of the gyro. The aircraft actually rotates around the rotating gyro, not the other way around. As the instrument case and the aircraft revolve around the vertical axis of the gyro, the card provides clear and accurate heading information.

Because of precession caused by friction, the heading indicator creeps or drifts from its set position. Among other factors, the amount of drift depends largely upon the condition of the instrument. If the bearings are worn, dirty, or improperly lubricated, the drift may be excessive. Another error in the heading indicator is caused by the fact that the gyro is oriented in space, and the Earth rotates in space at a rate of 15° in 1 hour. Thus, discounting precession caused by friction, the heading indicator may indicate as much as 15° error per every hour of operation.

Some heading indicators referred to as horizontal situation indicators (HSI) receive a magnetic north reference from a magnetic slaving transmitter and generally need no adjustment. The magnetic slaving transmitter is called a magnetometer.

Attitude and Heading Reference System (AHRS)

Electronic flight displays have replaced free-spinning gyros with solid-state laser systems that are capable of flight at any attitude without tumbling. This capability is the result of the development of the Attitude and Heading Reference System (AHRS).

The AHRS sends attitude information to the PFD in order to generate the pitch and bank information of the attitude indicator. The heading information is derived from a magnetometer that senses the earth’s lines of magnetic flux. This information is then processed and sent out to the PFD to generate the heading display. [Figure 9]

The Flux Gate Compass System

As mentioned earlier, the lines of flux in the Earth’s magnetic field have two basic characteristics: a magnet aligns with them, and an electrical current is induced, or generated, in any wire crossed by them.

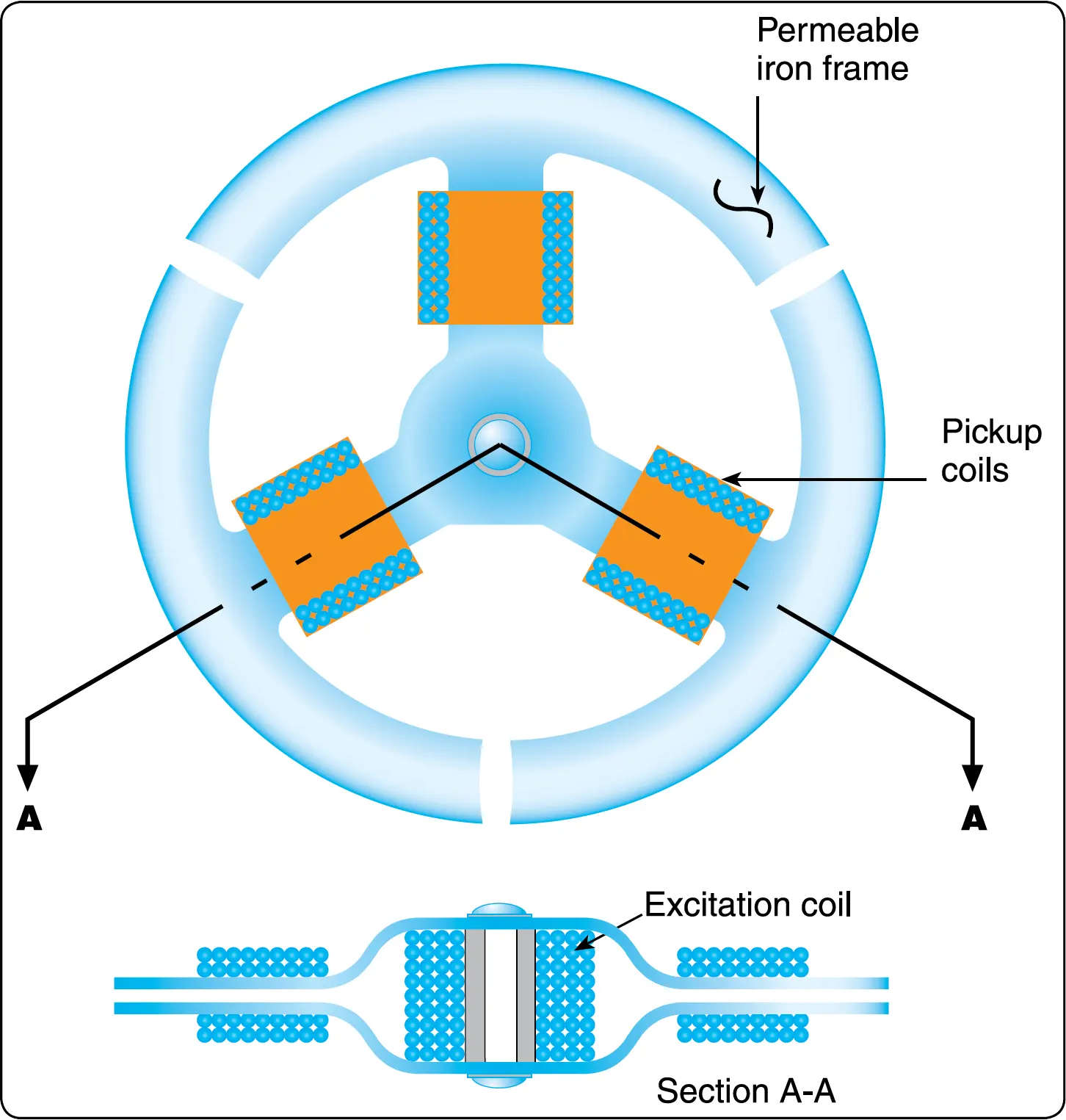

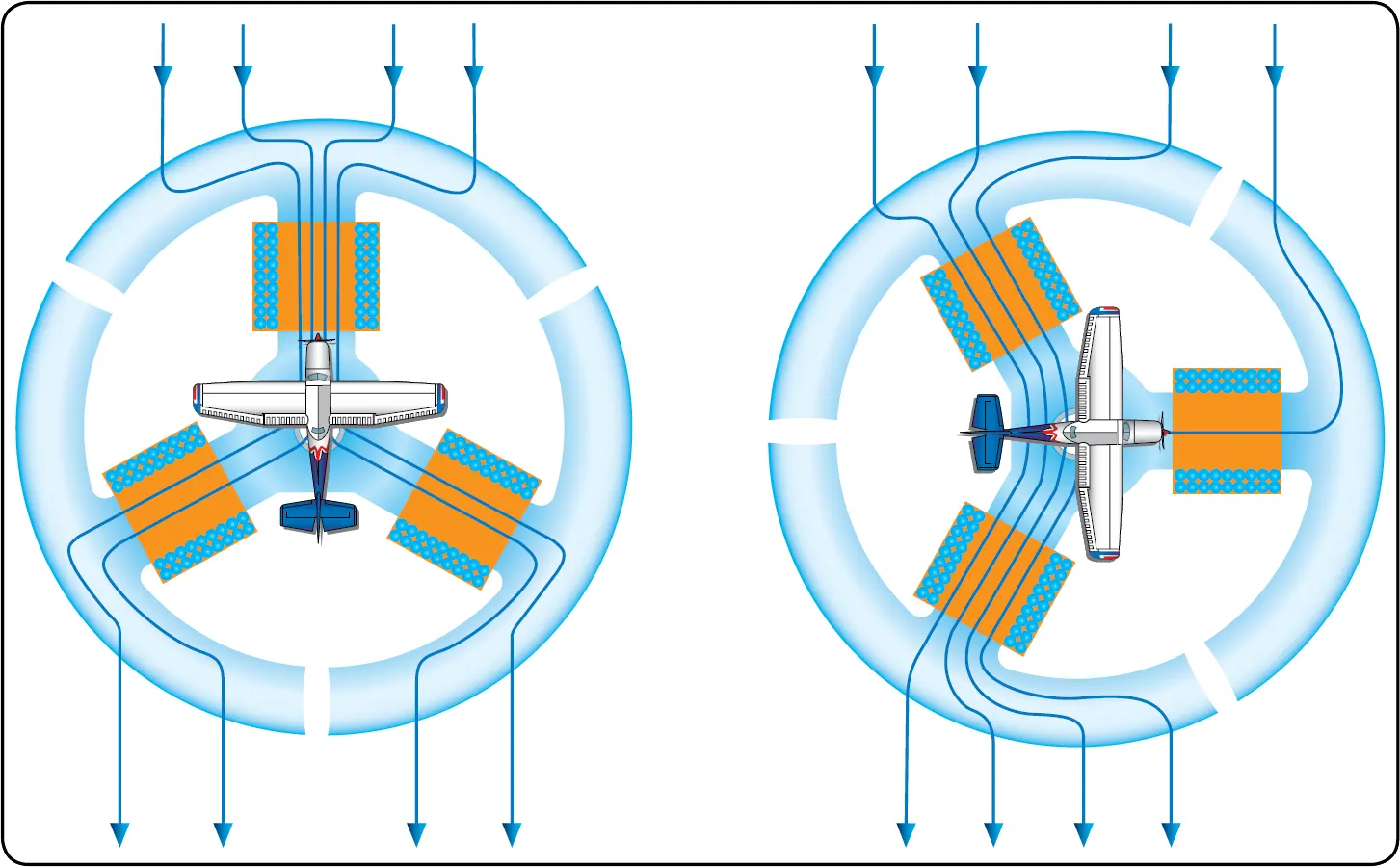

The flux gate compass that drives slaved gyros uses the characteristic of current induction. The flux valve is a small, segmented ring, like the one in Figure 10, made of soft iron that readily accepts lines of magnetic flux. An electrical coil is wound around each of the three legs to accept the current induced in this ring by the Earth’s magnetic field. A coil wound around the iron spacer in the center of the frame has 400 Hz alternating current (AC) flowing through it. During the times when this current reaches its peak, twice during each cycle, there is so much magnetism produced by this coil that the frame cannot accept the lines of flux from the Earth’s field.

As the current reverses between the peaks, it demagnetizes the frame so it can accept the flux from the Earth’s field. As this flux cuts across the windings in the three coils, it causes current to flow in them. These three coils are connected in such a way that the current flowing in them changes as the heading of the aircraft changes. [Figure 11]

The three coils are connected to three similar but smaller coils in a synchro inside the instrument case. The synchro rotates the dial of a radio magnetic indicator (RMI) or a HSI.

Remote Indicating Compass

Remote indicating compasses were developed to compensate for the errors and limitations of the older type of heading indicators. The two panel-mounted components of a typical system are the pictorial navigation indicator and the slaving control and compensator unit. [Figure 12] The pictorial navigation indicator is commonly referred to as an HSI.

The slaving control and compensator unit has a push button that provides a means of selecting either the “slaved gyro” or “free gyro” mode. This unit also has a slaving meter and two manual heading-drive buttons. The slaving meter indicates the difference between the displayed heading and the magnetic heading. A right deflection indicates a clockwise error of the compass card; a left deflection indicates a counterclockwise error. Whenever the aircraft is in a turn and the card rotates, the slaving meter shows a full deflection to one side or the other. When the system is in “free gyro” mode, the compass card may be adjusted by depressing the appropriate heading-drive button.

A separate unit, the magnetic slaving transmitter, is mounted remotely, usually in a wingtip to eliminate the possibility of magnetic interference. It contains the flux valve, which is the direction-sensing device of the system. A concentration of lines of magnetic force, after being amplified, becomes a signal relayed to the heading indicator unit, which is also remotely mounted. This signal operates a torque motor in the heading indicator unit that processes the gyro unit until it is aligned with the transmitter signal. The magnetic slaving transmitter is connected electrically to the HSI.

There are a number of designs of the remote indicating compass; therefore, only the basic features of the system are covered here. Instrument pilots must become familiar with the characteristics of the equipment in their aircraft.

As instrument panels become more crowded and the pilot’s available scan time is reduced by a heavier flight deck workload, instrument manufacturers have worked toward combining instruments. One good example of this is the RMI in Figure 13. The compass card is driven by signals from the flux valve, and the two pointers are driven by an automatic direction finder (ADF) and a very high frequency (VHF) omni-directional radio range (VOR).

Heading indicators that do not have this automatic northseeking capability are called “free” gyros and require periodic adjustment. It is important to check the indications frequently (approximately every 15 minutes) and reset the heading indicator to align it with the magnetic compass when required. Adjust the heading indicator to the magnetic compass heading when the aircraft is straight and level at a constant speed to avoid compass errors.

The bank and pitch limits of the heading indicator vary with the particular design and make of instrument. On some heading indicators found in light aircraft, the limits are approximately 55° of pitch and 55° of bank. When either of these attitude limits is exceeded, the instrument “tumbles” or “spills” and no longer gives the correct indication until reset. After spilling, it may be reset with the caging knob. Many of the modern instruments used are designed in such a manner so that they do not tumble.

An additional precession error may occur due to a gyro not spinning fast enough to maintain its alignment. When the vacuum system stops producing adequate suction to maintain the gyro speed, the heading indicator and the attitude indicator gyros begin to slow down. As they slow, they become more susceptible to deflection from the plane of rotation. Some aircraft have warning lights to indicate that a low vacuum situation has occurred. Other aircraft may have only a vacuum gauge that indicates the suction.

Instrument Check

As the gyro spools up, make sure there are no abnormal sounds. While taxiing, the instrument should indicate turns in the correct direction, and precession should be normal. At idle power settings, the gyroscopic instruments using the vacuum system might not be up to operating speeds and precession might occur more rapidly than during flight.