The engine oil system performs several important functions:

- Lubrication of the engine’s moving parts

- Cooling of the engine by reducing friction

- Removing heat from the cylinders

- Providing a seal between the cylinder walls and pistons

- Carrying away contaminants

https://aircraftsystemstech.com/humix/video/UIWeIoRjlIf

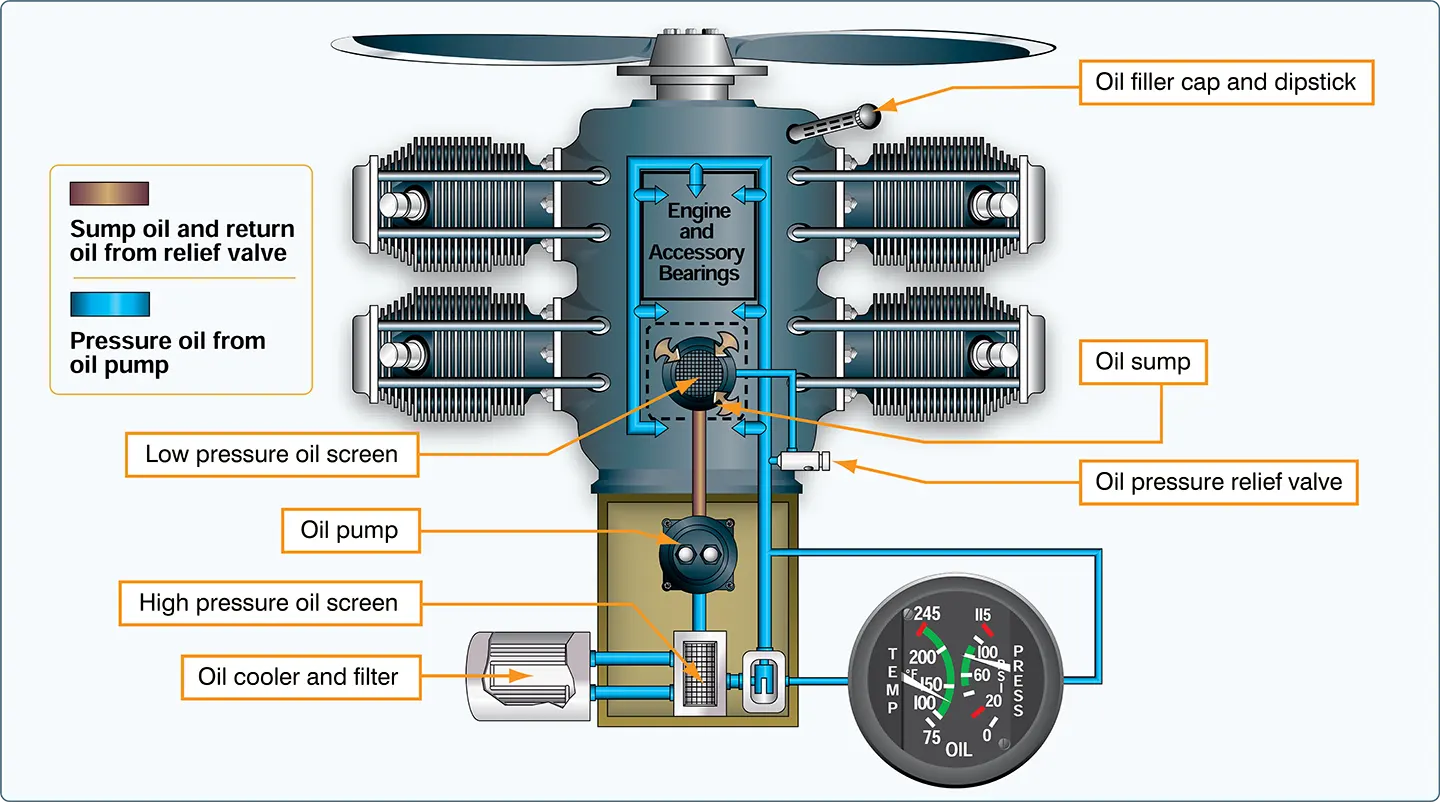

Reciprocating engines use either a wet-sump or a dry-sump oil system. In a wet-sump system, the oil is located in a sump that is an integral part of the engine. In a dry-sump system, the oil is contained in a separate tank and circulated through the engine by pumps. [Figure 1]

The main component of a wet-sump system is the oil pump, which draws oil from the sump and routes it to the engine. After the oil passes through the engine, it returns to the sump. In some engines, additional lubrication is supplied by the rotating crankshaft, which splashes oil onto portions of the engine.

An oil pump also supplies oil pressure in a dry-sump system, but the source of the oil is located external to the engine in a separate oil tank. After oil is routed through the engine, it is pumped from the various locations in the engine back to the oil tank by scavenge pumps. Dry-sump systems allow for a greater volume of oil to be supplied to the engine, which makes them more suitable for very large reciprocating engines.

The oil pressure gauge provides a direct indication of the oil system operation. It ensures the pressure in pounds per square inch (psi) of the oil supplied to the engine. Green indicates the normal operating range, while red indicates the minimum and maximum pressures. There should be an indication of oil pressure during engine start. Refer to the AFM/POH for manufacturer limitations.

The oil temperature gauge measures the temperature of oil. A green area shows the normal operating range, and the red line indicates the maximum allowable temperature. Unlike oil pressure, changes in oil temperature occur more slowly. This is particularly noticeable after starting a cold engine, when it may take several minutes or longer for the gauge to show any increase in oil temperature.

Check oil temperature periodically during flight especially when operating in high or low ambient air temperature. High oil temperature indications may signal a plugged oil line, a low oil quantity, a blocked oil cooler, or a defective temperature gauge. Low oil temperature indications may signal improper oil viscosity during cold weather operations.

The oil filler cap and dipstick (for measuring the oil quantity) are usually accessible through a panel in the engine cowling. If the quantity does not meet the manufacturer’s recommended operating levels, oil should be added. The AFM/POH or placards near the access panel provide information about the correct oil type and weight, as well as the minimum and maximum oil quantity. [Figure 2]