This section deals with systems and equipment that are generally installed in multiengine airplanes. Multiengine airplanes share many features with complex single-engine airplanes. However, there are certain features that are found more often in airplanes with two or more engines.

Feathering Propellers

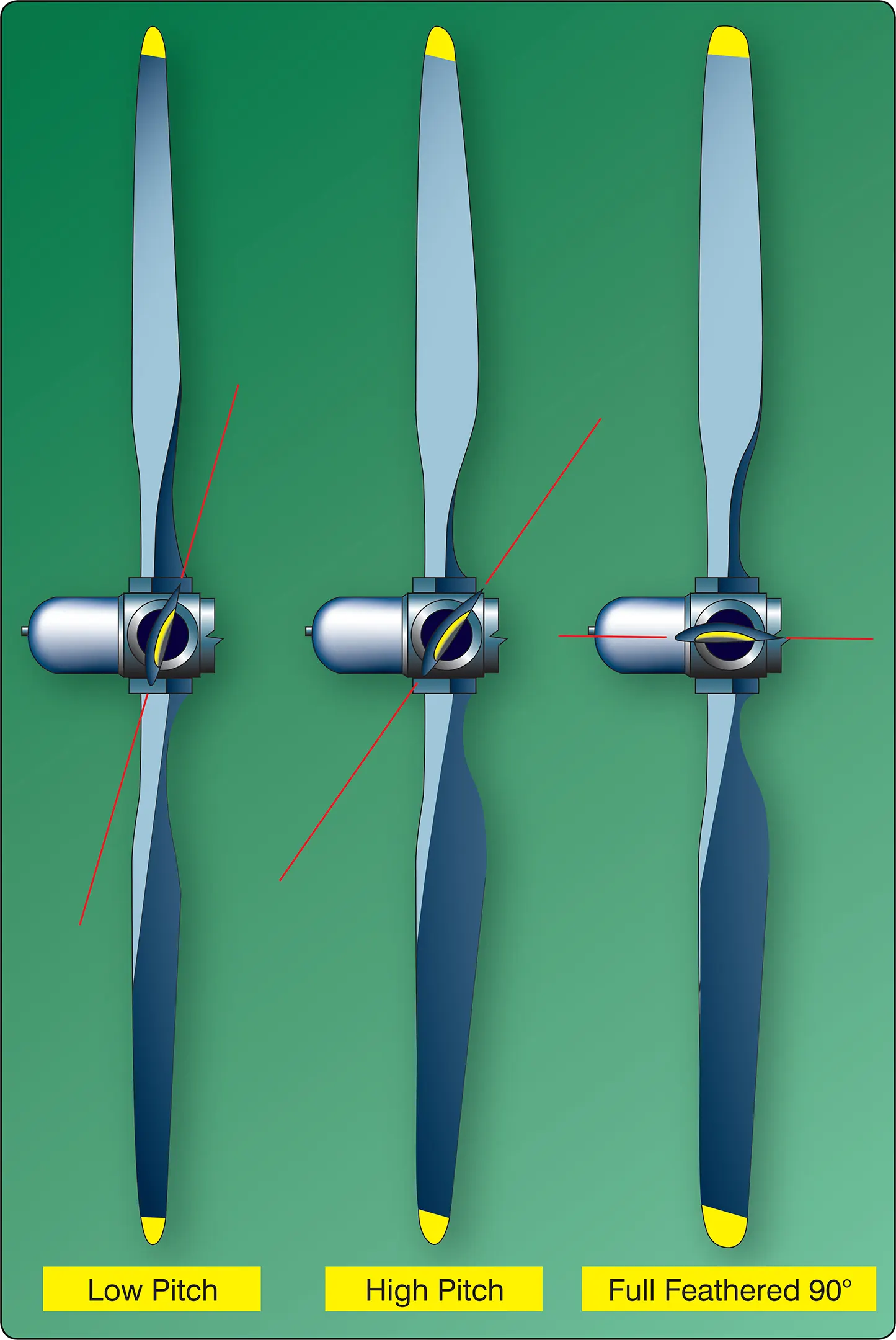

Although the propellers of a multiengine airplane may appear identical to a constant-speed propeller used in many single-engine airplanes, this is usually not the case. The pilot of a typical multiengine airplane can feather the propeller of an inoperative engine. Since it stops engine rotation with the propeller blade streamlined with the airplane’s relative wind, feathering the propeller of an inoperative engine minimizes propeller drag. [Figure 1] Depending upon single-engine performance, this feature often permits continued flight to a suitable airport following an engine failure.

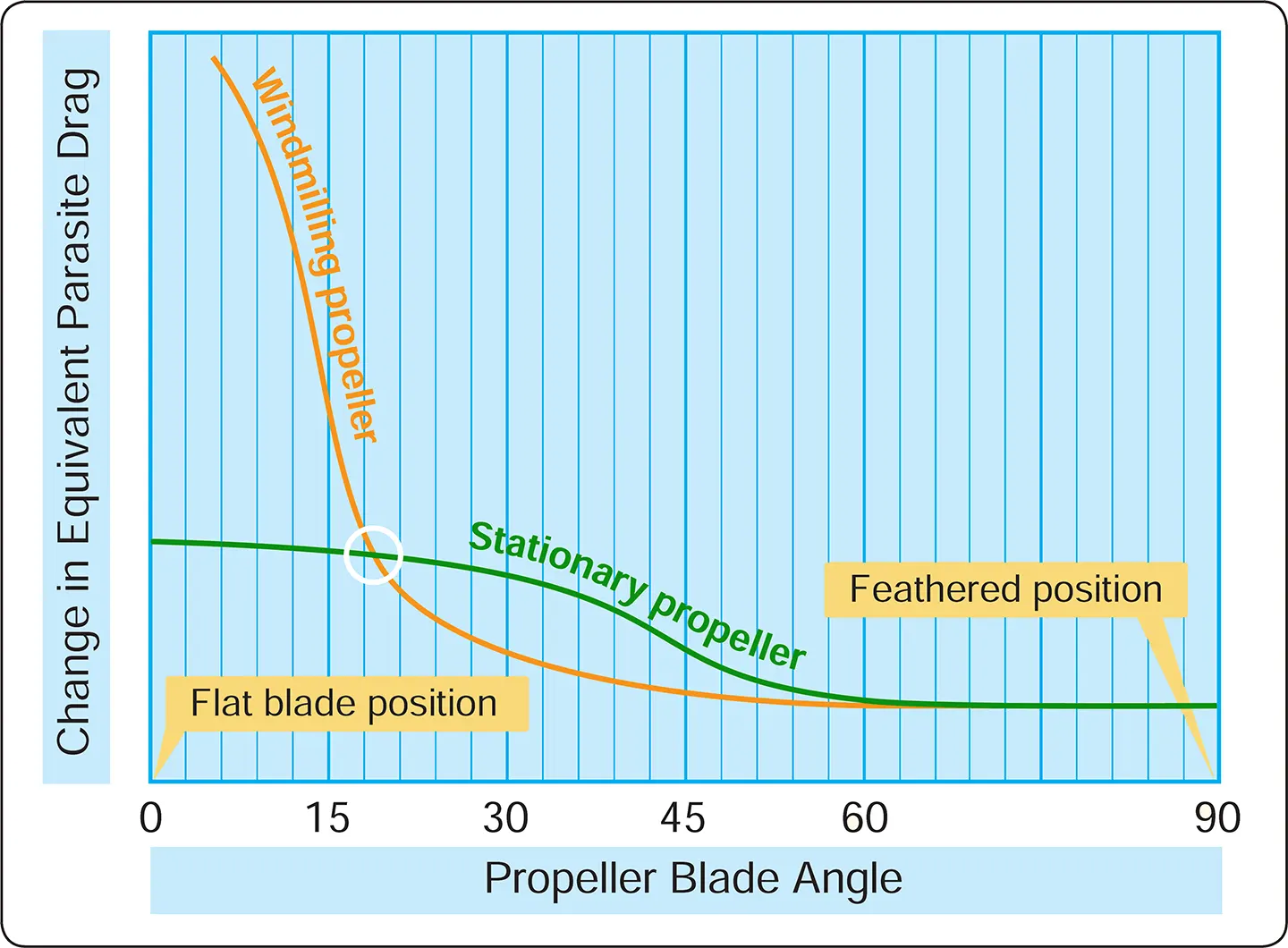

Feathering is important because of the change in parasite drag with propeller blade angle. [Figure 2] When the propeller blade angle is in the feathered position, parasite drag from the propeller is at a minimum. In a typical multiengine airplane, the parasite drag from a single, feathered propeller is a small part the airplane’s total drag.

At the smaller blade angles near the flat pitch position, the drag added by the propeller is large. At these small blade angles, the propeller windmilling at high revolutions per minute (rpm) can create enough drag to make the airplane difficult or impossible to control. A propeller windmilling at high speed in the low range of blade angles can produce parasite drag as great as the parasite drag of the entire airframe.

As a review, the constant-speed propellers on almost all single-engine airplanes are of the non-feathering, oil-pressure-to-increase pitch design. In this design, increased oil pressure from the propeller governor drives the blade angle towards high pitch, low rpm.

In contrast, the constant-speed propellers installed on most multiengine airplanes are full feathering, counterweighted, oil-pressure-to decrease-pitch designs. In this design, increased oil pressure from the propeller governor drives the blade angle toward low pitch, high rpm—away from the feather blade angle. In effect, the only thing that keeps these propellers from feathering is a constant supply of high-pressure engine oil. This is a necessity to enable propeller feathering in the event of a loss of oil pressure or a propeller governor failure.

Aerodynamic forces acting upon a windmilling propeller tend to drive the blades to low pitch, high rpm. Counterweights attached to the shank of each blade tend to force the blades to high pitch, low rpm. Inertia, or the apparent force (called centrifugal force) acting through the counterweights, is generally slightly greater than the aerodynamic forces. Therefore, centrifugal force would drive the blades to high pitch and low rpm were it not for an additional force acting through the propeller governor. A controlling force generated from high pressure oil from the propeller governor pushes the propeller blade angles toward low pitch and high rpm. Thus, a reduction in oil pressure allows the counterweights to drive the blades to a higher pitch and decreases engine rpm. [Figure 3]

To feather the propeller, the propeller control is brought fully aft. All oil pressure is dumped from the governor, and the counterweights drive the propeller blades toward feather. As centrifugal force acting on the counterweights decays from decreasing rpm, additional forces are needed to completely feather the blades. This additional force comes from either a spring or high-pressure air stored in the propeller dome, which forces the blades into the feathered position. The entire process may take up to 10 seconds.

Feathering a propeller only alters blade angle and stops engine rotation. To completely secure the engine, the pilot turns off the fuel (mixture, electric boost pump, and fuel selector), ignition, alternator/generator, and closes the cowl flaps. If the airplane is pressurized, there may also be an air bleed to close for the failed engine. Some airplanes are equipped with firewall shutoff valves that secure several of these systems with a single switch.

Completely securing a failed engine may not be necessary or even desirable depending upon the failure mode, altitude, and time available. The position of the fuel controls, ignition, and alternator/generator switches of the failed engine has no effect on aircraft performance, and the pilot might manipulate the incorrect switch under conditions of haste or pressure.

To unfeather a propeller, the engine should be rotated so that oil pressure can be generated to move the propeller blades from the feathered position. The ignition is turned on prior to engine rotation with the throttle at low idle and the mixture rich. With the propeller control in a high rpm position, the starter is engaged. The engine begins to windmill, start, and run as oil pressure moves the blades out of feather. As the engine starts, the propeller rpm should be immediately reduced until the engine has had several minutes to warm up; the pilot should monitor cylinder head and oil temperatures.

An unfeathering accumulator is a device that permits starting a feathered engine in-flight without the use of the electric starter. An accumulator is any device that stores a reserve of high pressure. On multiengine airplanes, the unfeathering accumulator stores a small reserve of engine oil under pressure from compressed air or nitrogen. To start a feathered engine in-flight, the pilot moves the propeller control out of the feather position to release the accumulator pressure. The oil flows under pressure to the propeller hub and drives the blades toward the high rpm, low pitch position, whereupon the propeller usually begins to windmill.

If fuel and ignition are present, the engine starts and runs. High oil pressure from the propeller governor recharges the accumulator just moments after engine rotation begins making it available for another unfeathering cycle, if needed. For airplanes used in training, an unfeathering accumulator may prolong the life of the electric starter and battery. If the accumulator fails to bring the propeller out of feather, the electric starter may be engaged.

In any event, the AFM/POH procedures should be followed for the exact unfeathering procedure. Both feathering and starting a feathered reciprocating engine on the ground are strongly discouraged by manufacturers due to the excessive stress and vibrations generated.

As just described, a loss of oil pressure from the propeller governor allows the counterweights, spring, and/or dome charge to drive the blades to feather. Logically then, the propeller blades should feather every time an engine is shut down as oil pressure falls to zero. However, below approximately 800 rpm, a reduction in centrifugal force allows small anti-feathering lock pins in the pitch changing mechanism of the propeller hub to move into place and block feathering. Therefore, if a propeller is to be feathered, it needs to be done before engine rpm decays below approximately 800. On one popular model of turboprop engine, the propeller blades do, in fact, feather with each shutdown. This propeller is not equipped with such centrifugally-operated pins due to a unique engine design.

Propeller Synchronization

Many multiengine airplanes have a propeller synchronizer (prop sync) installed to eliminate the annoying “drumming” or “beat” of propellers whose rpm are close, but not precisely the same. To use prop sync, the propeller rpms are coarsely matched by the pilot and the system is engaged. The prop sync adjusts the rpm of the “slave” engine to precisely match the rpm of the “master” engine and then maintains that relationship.

The prop sync should be disengaged when the pilot selects a new propeller rpm and then re-engaged after the new rpm is set. The prop sync should always be off for takeoff, landing, and single-engine operation. The AFM/POH should be consulted for system description and limitations.

A variation on the propeller synchronizer is the propeller synchrophaser. A propeller synchrophaser acts much like a synchronizer to precisely match rpm, but the synchrophaser goes one step further. It not only matches rpm but actually compares and adjusts the positions of the individual blades of the propellers in their arcs. There can be significant propeller noise and vibration reductions with a propeller synchrophaser. From the pilot’s perspective, operation of a propeller synchronizer and a propeller synchrophaser are very similar. A synchrophaser is also commonly referred to as prop sync, although that is not entirely correct nomenclature from a technical standpoint.

As a pilot aid to manually synchronizing the propellers, some twins have a small gauge mounted in or by the tachometer(s) with a propeller symbol on a disk that spins. The pilot manually fine tunes the engine rpm so as to stop disk rotation, thereby synchronizing the propellers. This is a useful backup to synchronizing engine rpm using the audible propeller beat. This gauge is also found installed with most propeller synchronizer and synchrophase systems. Some synchrophase systems use a knob for the pilot to control the phase angle.

Fuel Crossfeed

Fuel crossfeed systems are also unique to multiengine airplanes. Using crossfeed, an engine can draw fuel from a fuel tank located in the opposite wing.

On most multiengine airplanes, operation in the crossfeed mode is an emergency procedure used to extend airplane range and endurance in OEI flight. There are a few models that permit crossfeed as a normal, fuel balancing technique in normal operation, but these are not common. The AFM/POH describes crossfeed limitations and procedures that vary significantly among multiengine airplanes.

Checking crossfeed operation on the ground with a quick repositioning of the fuel selectors does nothing more than ensure freedom of motion of the handle. To actually check crossfeed operation, a complete, functional crossfeed system check should be accomplished. To do this, each engine should be operated from its crossfeed position during the run-up. The engines should be checked individually and allowed to run at moderate power (1,500 rpm minimum) for at least 1 minute to ensure that fuel flow can be established from the crossfeed source. Upon completion of the check, each engine should be operated for at least 1 minute at moderate power from the main (takeoff) fuel tanks to reconfirm fuel flow prior to takeoff.

This suggested check is not required prior to every flight. Crossfeed lines are ideal places for water and debris to accumulate unless they are used from time to time and drained using their external drains during preflight. Crossfeed is ordinarily not used for completing a flight with one engine inoperative when an alternate airport is nearby. Pilots should never use crossfeed during takeoff or for normal landing operations with both engines operating. A landing with one engine inoperative using crossfeed may be necessary if setting normal fuel flow would cause the operative engine to fail.

Combustion Heater

Combustion heaters are another common item on multiengine airplanes not found on single-engine airplanes. A combustion heater is best described as a small furnace that burns gasoline to produce heated air for occupant comfort and windshield defogging. Most are thermostatically operated and have a separate hour meter to record time in service for maintenance purposes. Automatic over-temperature protection is provided by a thermal switch mounted on the unit that cannot be accessed in flight. This requires the pilot or mechanic to visually inspect the unit for possible heat damage in order to reset the switch.

Manufacturers often suggest a cool-down period when shutting down a combustion heater. Most heater instructions recommend that outside air be permitted to circulate through the unit for at least 15 seconds in flight or that the ventilation fan can be operated for at least 2 minutes on the ground. Failure to provide an adequate cool down usually trips the thermal switch and renders the heater inoperative until the switch is reset.

Flight Director/Autopilot

Multiengine airplanes are often equipped with flight director/autopilot (FD/AP) systems. The system integrates pitch, roll, heading, altitude, and radio navigation signals in a computer. The outputs, called computed commands, are displayed on a flight command indicator (FCI). The FCI replaces the conventional attitude indicator on the instrument panel. The FCI is occasionally referred to as a flight director indicator (FDI) or as an attitude director indicator (ADI).

The entire flight director/autopilot system is called an integrated flight control system (IFCS) by some manufacturers. Others may use the term automatic flight control system (AFCS).

The FD/AP system may be employed at the following different levels:

- Off (raw data)

- Flight director (computed commands)

- Autopilot

With the system off, the FCI operates as an ordinary attitude indicator. On most FCIs, the command bars are biased out of view when the FD is off. The pilot maneuvers the airplane as though the system were not installed.

To maneuver the airplane using the FD, the pilot enters the desired modes of operation (heading, altitude, navigation (NAV) intercept, and tracking) on the FD/AP mode controller. The computed flight commands are then displayed to the pilot through either a single-cue or dual-cue system in the FCI. On a single-cue system, the commands are indicated by “V” bars. On a dual-cue system, the commands are displayed on two separate command bars, one for pitch and one for roll. To maneuver the airplane using computed commands, the pilot “flies” the symbolic airplane of the FCI to match the steering cues presented.

On most systems, the FD needs to be operating to engage the autopilot. At any time thereafter, the pilot may engage the autopilot through the mode controller. The autopilot then maneuvers the airplane to satisfy the computed commands of the FD.

Like any computer, the FD/AP system only does what it is told. The pilot should ensure that it has been programmed properly for the particular phase of flight desired. The armed and/or engaged modes are usually displayed on the mode controller or separate annunciator lights. When the airplane is being hand-flown, if the FD is not being used at any particular moment, it should be off so that the command bars are pulled from view.

Prior to system engagement, all FD/AP computer and trim checks should be accomplished. Many newer systems cannot be engaged without the completion of a self-test. The pilot should also be familiar with various methods of disengagement, both normal and emergency. System details, including approvals and limitations, can be found in the supplements section of the AFM/POH. Additionally, many avionics manufacturers can provide informative pilot operating guides upon request.

Yaw Damper

The yaw damper is a servo that moves the rudder in response to inputs from a gyroscope or accelerometer that detects yaw rate or lateral Gs, respectively. The yaw damper reduces motion about the vertical axis caused by turbulence. (Yaw dampers on swept wing airplanes provide another, more vital function of damping Dutch roll characteristics.) Occupants feel a smoother ride, particularly if seated in the rear of the airplane, when the yaw damper is engaged. The yaw damper should be off for takeoff and landing. There may be additional restrictions against its use with one engine inoperative. Most yaw dampers can be engaged independently of the autopilot.

Alternator/Generator

On a multiengine aircraft, each engine has an alternator or generator installed. Alternator or generator paralleling circuitry matches the output of each engine’s alternator/generator so that the electrical system load is shared equally between them. In the event of an alternator/generator failure, the inoperative unit can be isolated, and the entire electrical system powered from the remaining one. Depending upon the electrical capacity of the alternator/generator, the pilot may need to reduce the electrical load (referred to as load shedding) when operating on a single unit. The AFM/POH contains system description and limitations.

Nose Baggage Compartment

Nose baggage compartments are common on multiengine airplanes (and are even found on a few single-engine airplanes). There is nothing strange or exotic about a nose baggage compartment, and the usual guidance concerning observation of load limits applies. Pilots occasionally neglect to secure the latches properly. When improperly secured, the door may open and the contents may be drawn out, usually into the propeller arc and just after takeoff. Even when the nose baggage compartment is empty, airplanes have been lost when the pilot became distracted by the open door. Security of the nose baggage compartment latches and locks is a vital preflight item.

Most airplanes continue to fly with a nose baggage door open. There may be some buffeting from the disturbed airflow, and there is an increase in noise. Pilots should never become so preoccupied with an open door (of any kind) that they fail to fly the airplane.

Inspection of the compartment interior is another important preflight item. More than one pilot has been surprised to find a supposedly empty compartment packed to capacity or loaded with ballast. The tow bars, engine inlet covers, windshield sun screens, oil containers, spare chocks, and miscellaneous small hand tools that find their way into baggage compartments should be secured to prevent damage from shifting in flight.

Anti-Icing/Deicing Equipment

Anti-icing/deicing equipment is frequently installed on multiengine airplanes and may consist of a combination of different systems. These may be classified as either anti-icing or deicing, depending upon function. The presence of anti-icing and deicing equipment, even though it may appear elaborate and complete, does not necessarily mean that the airplane is approved for flight in icing conditions. The AFM/POH, placards, and even the manufacturer should be consulted for specific determination of approvals and limitations. Anti-icing equipment is provided to prevent ice from forming on certain protected surfaces. Examples of anti-icing equipment include heated pitot tubes, heated or non-icing static ports and fuel vents, propeller blades with electrothermal boots or alcohol slingers, windshields with alcohol spray or electrical resistance heating, windshield defoggers, and heated stall warning lift detectors. On many turboprop engines, the “lip” surrounding the air intake is heated either electrically or with bleed air. In the absence of AFM/POH guidance to the contrary, anti-icing equipment should be actuated prior to flight into known or suspected icing conditions.

Deicing equipment is generally limited to pneumatic boots on wing and tail leading edges. Deicing equipment is installed to remove ice that has already formed on protected surfaces. Upon pilot actuation, the boots inflate with air from the pneumatic pumps to break off accumulated ice. After a few seconds of inflation, they are deflated back to their normal position with the assistance of a vacuum. The pilot monitors the buildup of ice and cycles the boots as directed in the AFM/POH. An ice light on the left engine nacelle allows the pilot to monitor wing ice accumulation at night.

Other airframe equipment necessary for flight in icing conditions includes an alternate induction air source and an alternate static system source. Ice tolerant antennas are also installed.

In the event of impact ice accumulating over normal engine air induction sources, carburetor heat (carbureted engines) or alternate air (fuel-injected engines) should be selected. Ice buildup on normal induction sources can be detected by a loss of engine rpm with fixed-pitch propellers and a loss of manifold pressure with constant-speed propellers. On some fuel-injected engines, an alternate air source is automatically activated with blockage of the normal air source.

An alternate static system provides an alternate source of static air for the pitot-static system in the unlikely event that the primary static source becomes blocked. In non-pressurized airplanes, most alternate static sources are plumbed to the cabin. On pressurized airplanes, they are usually plumbed to a non-pressurized baggage compartment. The pilot may activate the alternate static source by opening a valve or a fitting in the flight deck. Activation may create airspeed indicator, altimeter, or vertical speed indicator (VSI) errors. A correction table is frequently provided in the AFM/POH.

Anti-icing/deicing equipment only eliminates ice from the protected surfaces. Significant ice accumulations may form on unprotected areas, even with proper use of anti-ice and deice systems. Flight at high angles of attack (AOA) or even normal climb speeds permit significant ice accumulations on lower wing surfaces, which are unprotected. Many AFM/POHs provide minimum speeds to be maintained in icing conditions. Degradation of all flight characteristics and large performance losses can be expected with ice accumulations. Pilots should not rely upon the stall warning devices for adequate stall warning with ice accumulations.

Ice accumulates unevenly on the airplane. It adds weight and drag (primarily drag) and decreases thrust and lift. Even wing shape affects ice accumulation; thin airfoil sections are more prone to ice accumulation than thick, highly-cambered sections. For this reason, certain surfaces, such as the horizontal stabilizer, are more prone to icing than the wing. With ice accumulations, landing approaches should be made with a minimum wing flap setting (flap extension increases the AOA of the horizontal stabilizer) and with an added margin of airspeed. Sudden and large configuration and airspeed changes should be avoided.

Unless otherwise recommended in the AFM/POH, the autopilot should not be used in icing conditions. Continuous use of the autopilot masks trim and handling changes that occur with ice accumulation. Without this control feedback, the pilot may not be aware of ice accumulation building to hazardous levels. The autopilot suddenly disconnects when it reaches design limits, and the pilot may find the airplane has assumed unsatisfactory handling characteristics.

The installation of anti-ice/deice equipment on airplanes without AFM/POH approval for flight into icing conditions is to facilitate escape when such conditions are inadvertently encountered. Even with AFM/POH approval, the prudent pilot avoids icing conditions to the maximum extent practicable and avoids extended flight in any icing conditions. No multiengine airplane is approved for flight into severe icing conditions and none are intended for indefinite flight in continuous icing conditions.