Jet Engine Basics

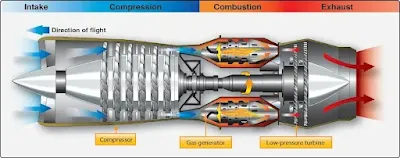

A jet engine is a gas turbine with basic cycle of operation; that is, induction, compression, combustion, expansion, and exhaust. Air passes through the intake and enters the compressor section, which is made up of a series of fan blades or “stages.” The first stage, visible from the front of the engine, is the largest diameter and has the biggest blades. Each subsequent stage contains smaller diameter and thinner blades of increasing pitch. The compression in each stage raises the air temperature and pressure. The high-pressure hot air enters the combustion chamber where fuel is added. During engine start, igniters set the fuel air mixture on fire, after which the fire is self-sustaining. The rapidly expanding air flows to the turbine section, which like the compressor section, consists of a series of fan blade stages. The turbine section extracts a portion of the available energy from the airflow to turn a shaft, which drives the compressor. The remaining energy causes rapid air expansion in the nozzle of the tail pipe, accelerates the gas to a high velocity, and produces thrust. [Figure 1]

|

| Figure 1. Basic turbojet engine |

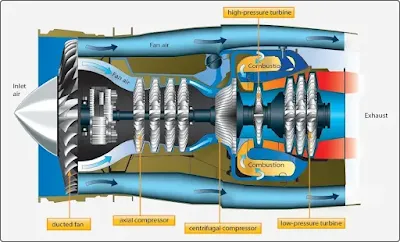

In a turbofan engine, the compressor and turbine sections divide into sub-sections. Each sub-section in the turbine section connects to a specific sub-section of the compressor section via a split-spool shaft. [Figure 2]

|

| Figure 2. Turbofan engine |

Air drawn into the engine for the gas generator is further compressed and constitutes the core airflow. While a turbojet engine uses the entire gas generator’s output to produce thrust in the form of a high-velocity exhaust gas jet, the lower velocity and cooler bypass air produces some of the thrust produced by a turbofan engine.

The turbofan engine design increases the thrust of the jet engine, particularly at lower speeds and altitudes. Although less efficient at higher altitudes, the turbofan engine increases acceleration, decreases the takeoff roll, improves initial climb performance, and often has the effect of decreasing fuel consumption.

Operating the Jet Engine

In a jet engine, the amount of fuel injected into the combustion chamber controls thrust. Because most engine control functions are automatic, the power controls on most turbojet-powered and turbofan-powered airplanes consist of just one thrust lever for each engine. The thrust lever links to a fuel control and/or electronic engine computer that meters fuel flow based on revolutions per minute (rpm), internal temperatures, ambient conditions, and other factors.

Typically in jet airplanes, there are flight deck indications for the rotation speed of each major engine section. Each engine section rotates at many thousands of rpm. For ease of interpretation, the indications read as percent of rpm rather than actual rpm. Depending on the make and model, there are usually indications for fuel flow, as well as for gas temperatures and pressures. The associated engine indications have different names according to their location.

As in any gas turbine engine, exceeding temperature or rpm limits, even for a few seconds, may result in serious damage to turbine blades and other components. The pilot should monitor the temperature of turbine gases and rotation speeds as needed. Modern aircraft are designed to prevent exceedances and alert the pilot of an impending or actual exceedance. Older designs rely more on the pilot to prevent any exceedances.

Setting Power

When setting power, the pilot normally uses pressure or rpm indications to set maximum allowable thrust. However, the forward movement of the thrust levers should be stopped for any limitation (e.g., pressure, rpm, or temperature).

Thrust to Thrust Lever Relationship

In a jet engine, thrust output changes much more per increment of throttle movement at high engine speeds. If the power setting is already high, it normally takes a small amount of movement to change the power output. This is a significant difference for the pilot transitioning to jet-powered airplanes. In a situation where significantly more thrust is needed and the jet engine is at low rpm, inching the thrust lever forward will have little effect. It this situation, the pilot needs to make a smooth and significant thrust lever position change to increase the power.

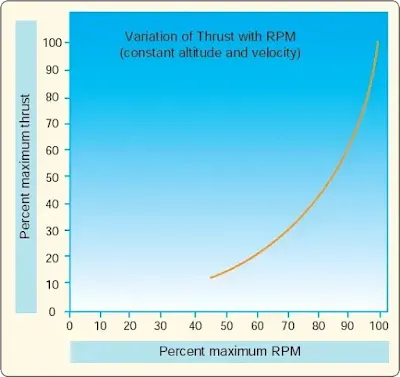

Variation of Thrust with RPM

Jets operate most efficiently in the 85 percent to 100 percent range. At idle rpm of approximately 55 percent to 60 percent, they produce a relatively small amount of thrust. An increase in rpm from 90 to 100 percent may increase thrust by as much as the total available at 70 percent. [Figure 3]

|

| Figure 3. Variation of thrust with rpm |

Slow Acceleration of the Jet Engine

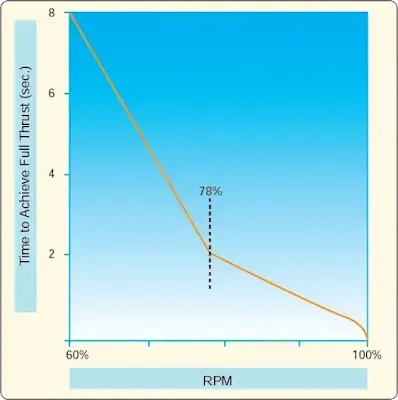

Acceleration of a piston engine from idle to full power is relatively rapid. The acceleration on different jet engines can vary considerably, but it is usually much slower. In some cases, the transition to full power could take up to 10 seconds. [Figure 4] Pilots should anticipate the need for adding power from low power settings.

|

| Figure 4. Typical jet engine acceleration times |

Jet Engine Efficiency

The efficiency of the jet engine increases in the cold temperatures found at high altitudes. The fuel consumption of jet engines decreases as the outside air temperature decreases for constant engine rpm and true airspeed (TAS). Thus, by flying at a high altitude, the airplane operates with improved fuel economy and speed. At high altitudes, engines may be operating close to rpm or temperature limits, and excess thrust may not be available. Therefore, pilots should accomplish all maneuvering within the limits of available thrust, stability, and controllability.