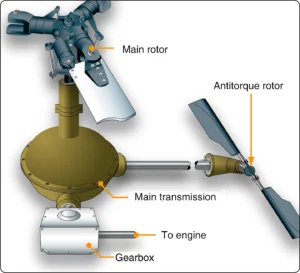

The transmission system transfers power from the engine to the main rotor, tail rotor, and other accessories during normal flight conditions. The main components of the transmission system are the main rotor transmission, tail rotor drive system, clutch, and freewheeling unit. The freewheeling unit or autorotative clutch allows the main rotor transmission to drive the tail rotor drive shaft during autorotation.

In some helicopter designs, such as the Bell BH-206, the freewheeling unit is located in the accessory gearbox. Because it is part of the transmission system, the transmission lubricates it to ensure free rotation. Helicopter transmissions are normally lubricated and cooled with their own oil supply. A sight gauge is provided to check the oil level.

Some transmissions have chip detectors located in the sump, to detect loose pieces of metal. These detectors are wired to warning lights located on the pilot’s instrument panel that illuminate in the event of an internal problem. Some chip detectors on modern helicopters have a “burn off” capability and attempt to correct the situation without pilot action. If the problem cannot be corrected on its own, the pilot must refer to the emergency procedures for that particular helicopter.

Main Rotor Transmission

The primary purpose of the main rotor transmission is to reduce engine output rpm to optimum rotor rpm. This reduction is different for the various helicopters. As an example, suppose the engine rpm of a specific helicopter is 2,700. A rotor speed of 450 rpm would require a 6:1 reduction. A 9:1 reduction would mean the rotor would turn at 300 rpm.

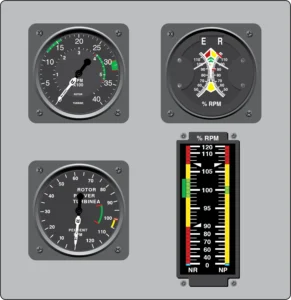

Dual Tachometers

Most helicopters use a dual-needle tachometer or a vertical scale instrument to show both engine and rotor rpm or a percentage of engine and rotor rpm. The rotor rpm indicator is used during clutch engagement to monitor rotor acceleration, and in autorotation to maintain rpm within prescribed limits. It is vital to understand that rotor rpm is paramount, and that engine rpm is secondary. If the rotor tachometer fails, rotor rpm can still be determined indirectly by the engine rpm during powered flight, because the engine drives the rotor at a fixed, one-to-one ratio (by virtue of the sprag clutch). There have been many accidents where the pilot responded to the rotor rpm tachometer failure and entered into autorotation while the engine was still operating.

Look closer at the markings on the gauges in Figure 1. All gauges shown are dual tachometer gauges.

The two on the left have two needles each, one marked with the letter ‘T’ (turbine) the other marked with the letter ‘R’ (rotor). The lower left gauge shows two arced areas within the same needle location. In this case, both needles should be nearly together or superimposed during normal operation. Note the top left gauge shows two numerical arcs. The outer arc, with larger numbers, applies one set of values to engine rpm. The inner arc, or smaller numbers, represents a separate set of values for rotor rpm. Normal operating limits are shown when the needles are married or appear superimposed. The top right gauge shows independent needles, focused toward the middle of the gauge, with colored limitation areas respective to the needle head. The left side represents engine operational parameters; the right, rotor operational parameters.

In normal conditions when the rotor is coupled to the engine, both needles move together in the same direction. However, with a sudden loss in engine power the needles “split” showing that the engine and rotor are no longer coupled as the clutch has disconnected. [Figure 2]

Many newer aircraft have what is referred to as a glass cockpit, meaning the instrumentation is digital and displayed to the pilot on digital screens and vertical scale instruments. The bottom right gauge in Figure 1 replicates a vertical scale instrument. The dual tachometer shown displays rotor rpm (NR) on the left and engine rpm (NP) on the right side of the vertical scale. Corresponding color limits are present for each component parameter.

Structural Design

In helicopters with horizontally mounted engines, another purpose of the main rotor transmission is to change the axis of rotation from the horizontal axis of the engine to the vertical axis of the rotor shaft. [Figure 3] This differs from airplanes, which have their propellers mounted directly to the crankshaft or to a shaft that is geared to the crankshaft.

Maintaining main rotor rpm is essential for adequate lift. RPM within normal limits produces adequate lift for normal maneuvering. Therefore, it is imperative not only to know the location of the tachometers, but also to understand the information they provide. If rotor rpm is allowed to go below normal limits, the outcome could be catastrophic.

Clutch

In a conventional airplane, the engine and propeller are permanently connected. However, in a helicopter they are not. Because of the greater weight of a rotor in relation to the power of the engine, as compared to the weight of a propeller and the power in an airplane, the rotor must be disconnected from the engine when the starter is engaged. A clutch allows the engine to be started and then gradually pick up the load of the rotor.

Freewheeling turbine engines do not require a separate clutch since the air coupling between the gas producer turbine and the power (takeoff) turbine functions as an air clutch for starting purposes. When the engine is started, there is little resistance from the power turbine. This enables the gas-producer turbine to accelerate to normal idle speed without the load of the transmission and rotor system dragging it down. As the gas pressure increases through the power turbine, the rotor blades begin to turn, slowly at first and then gradually accelerate to normal operating rpm.

On reciprocating and fixed turbine engines, a clutch is required to enable engine start. Air, or windmilling starts, are not possible. The two main types of clutches are the centrifugal clutch and the idler or manual clutch.

How the clutch engages the main rotor system during engine start differs between helicopter design. Piston-powered helicopters have a means of engaging the clutch manually just as a manual clutch in an automobile. This may be by means of an electric motor that positions a pulley when the engine is at the proper operating condition (oil temperature and pressure in the appropriate range), but which is controlled by a cockpit mounted switch.

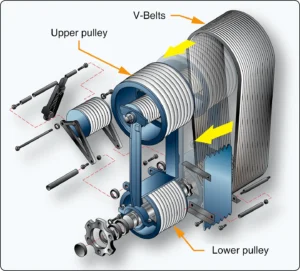

Belt Drive Clutch

Some helicopters utilize a belt drive to transmit power from the engine to the transmission. A belt drive consists of a lower pulley attached to the engine, an upper pulley attached to the transmission input shaft, a belt or a set of V-belts, and some means of applying tension to the belts. The belts fit loosely over the upper and lower pulley when there is no tension on the belts. [Figure 4]

Some aircraft utilize a clutch for starting. This allows the engine to be started without requiring power to turn the transmission. One advantage this concept has is that without a load on the engine starting may be accomplished with minimal throttle application. However, caution should also be used during starting, since rapid or large throttle inputs may cause overspeeds.

Once the engine is running, tension on the belts is gradually increased. When the rotor and engine tachometer needles are superimposed, the rotor and the engine are synchronized, and the clutch is then fully engaged. Advantages of this system include vibration isolation, simple maintenance. When the clutch is not engaged, engines are very easy to overspeed, resulting in costly inspections and maintenance. Power, or throttle control, is very important in this phase of engine operation.

Centrifugal Clutch

A centrifugal clutch is made up of an inner assembly and an outer drum. The inner assembly, which is connected to the engine driveshaft, consists of shoes lined with material similar to automotive brake linings. At low engine speeds, springs hold the shoes in, so there is no contact with the outer drum, which is attached to the transmission input shaft. As engine speed increases, centrifugal force causes the clutch shoes to move outward and begin sliding against the outer drum. The transmission input shaft begins to rotate, causing the rotor to turn slowly at first, but increasing as the friction increases between the clutch shoes and transmission drum.

As rotor speed increases, the rotor tachometer needle shows an increase by moving toward the engine tachometer needle. When the two needles are superimposed (in the case of a coaxial-type gage), the engine and the rotor are synchronized, indicating the clutch is fully engaged and there is no further slippage of the clutch shoes.

The turbine engine engages the clutch through centrifugal force, as stated above. Unless a rotor brake is used to separate the automatic engagement of the main driveshaft and subsequently the main rotor, the drive shaft turns at the same time as the engine and the inner drum of the freewheeling unit engages gradually to turn the main rotor system.