Airfoil Design

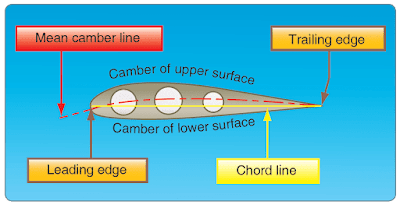

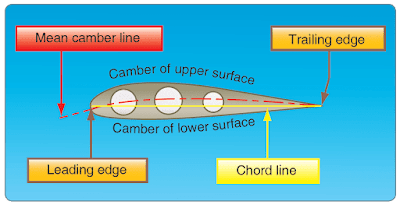

An airfoil is a structure designed to obtain reaction upon its surface from the air through which it moves or that moves past such a structure. Air acts in various ways when submitted to different pressures and velocities; but this discussion is confined to the parts of an aircraft that a pilot is most concerned with in flight—namely, the airfoils designed to produce lift. By looking at a typical airfoil profile, such as the cross section of a wing, one can see several obvious characteristics of design. [Figure 1] Notice that there is a difference in the curvatures (called cambers) of the upper and lower surfaces of the airfoil. The camber of the upper surface is more pronounced than that of the lower surface, which is usually somewhat flat.

|

| Figure 1. Typical airfoil section |

NOTE: The two extremities of the airfoil profile also differ in appearance. The rounded end, which faces forward in flight, is called the leading edge; the other end, the trailing edge, is quite narrow and tapered.

A reference line often used in discussing the airfoil is the chord line, a straight line drawn through the profile connecting the extremities of the leading and trailing edges. The distance from this chord line to the upper and lower surfaces of the wing denotes the magnitude of the upper and lower camber at any point. Another reference line, drawn from the leading edge to the trailing edge, is the mean camber line. This mean line is equidistant at all points from the upper and lower surfaces.

An airfoil is constructed in such a way that its shape takes advantage of the air’s response to certain physical laws. This develops two actions from the air mass: a positive pressure lifting action from the air mass below the wing, and a negative pressure lifting action from lowered pressure above the wing.

As the air stream strikes the relatively flat lower surface of a wing or rotor blade when inclined at a small angle to its direction of motion, the air is forced to rebound downward, causing an upward reaction in positive lift. At the same time, the air stream striking the upper curved section of the leading edge is deflected upward. An airfoil is shaped to cause an action on the air, and forces air downward, which provides an equal reaction from the air, forcing the airfoil upward. If a wing is constructed in such form that it causes a lift force greater than the weight of the aircraft, the aircraft will fly.

If all the lift required were obtained merely from the deflection of air by the lower surface of the wing, an aircraft would only need a flat wing like a kite. However, the balance of the lift needed to support the aircraft comes from the flow of air above the wing. Herein lies the key to flight.

It is neither accurate nor useful to assign specific values to the percentage of lift generated by the upper surface of an airfoil versus that generated by the lower surface. These are not constant values. They vary, not only with flight conditions, but also with different wing designs.

Different airfoils have different flight characteristics. Many thousands of airfoils have been tested in wind tunnels and in actual flight, but no one airfoil has been found that satisfies every flight requirement. The weight, speed, and purpose of each aircraft dictate the shape of its airfoil. The most efficient airfoil for producing the greatest lift is one that has a concave or “scooped out” lower surface. As a fixed design, this type of airfoil sacrifices too much speed while producing lift and is not suitable for high-speed flight. Advancements in engineering have made it possible for today’s high-speed jets to take advantage of the concave airfoil’s high lift characteristics. Leading edge (Kreuger) flaps and trailing edge (Fowler) flaps, when extended from the basic wing structure, literally change the airfoil shape into the classic concave form, thereby generating much greater lift during slow flight conditions.

On the other hand, an airfoil that is perfectly streamlined and offers little wind resistance sometimes does not have enough lifting power to take the airplane off the ground. Thus, modern airplanes have airfoils that strike a medium between extremes in design. The shape varies according to the needs of the airplane for which it is designed. Figure 2 shows some of the more common airfoil designs.

|

| Figure 2. Airfoil designs |

Low Pressure Above

In a wind tunnel or in flight, an airfoil is simply a streamlined object inserted into a moving stream of air. If the airfoil profile were in the shape of a teardrop, the speed and the pressure changes of the air passing over the top and bottom would be the same on both sides. But if the teardrop shaped airfoil were cut in half lengthwise, a form resembling the basic airfoil (wing) section would result. If the airfoil were then inclined so the airflow strikes it at an angle, the air moving over the upper surface would be forced to move faster than the air moving along the bottom of the airfoil. This increased velocity reduces the pressure above the airfoil.

Applying Bernoulli’s Principle of Pressure, the increase in the speed of the air across the top of an airfoil produces a drop in pressure. This lowered pressure is a component of total lift. The pressure difference between the upper and lower surface of a wing alone does not account for the total lift force produced.

The downward backward flow from the top surface of an airfoil creates a downwash. This downwash meets the flow from the bottom of the airfoil at the trailing edge. Applying Newton’s third law, the reaction of this downward backward flow results in an upward forward force on the airfoil.

High Pressure Below

A certain amount of lift is generated by pressure conditions underneath the airfoil. Because of the manner in which air flows underneath the airfoil, a positive pressure results, particularly at higher angles of attack. However, there is another aspect to this airflow that must be considered. At a point close to the leading edge, the airflow is virtually stopped (stagnation point) and then gradually increases speed. At some point near the trailing edge, it again reaches a velocity equal to that on the upper surface. In conformance with Bernoulli’s principle, where the airflow was slowed beneath the airfoil, a positive upward pressure was created (i.e., as the fluid speed decreases, the pressure must increase). Since the pressure differential between the upper and lower surface of the airfoil increases, total lift increases. Both Bernoulli’s Principle and Newton’s Laws are in operation whenever lift is being generated by an airfoil.

Pressure Distribution

From experiments conducted on wind tunnel models and on full size airplanes, it has been determined that as air flows along the surface of a wing at different angles of attack (AOA), there are regions along the surface where the pressure is negative, or less than atmospheric, and regions where the pressure is positive, or greater than atmospheric. This negative pressure on the upper surface creates a relatively larger force on the wing than is caused by the positive pressure resulting from the air striking the lower wing surface. Figure 3 shows the pressure distribution along an airfoil at three different angles of attack. The average of the pressure variation for any given AOA is referred to as the center of pressure (CP). Aerodynamic force acts through this CP. At high angles of attack, the CP moves forward, while at low angles of attack the CP moves aft. In the design of wing structures, this CP travel is very important, since it affects the position of the air loads imposed on the wing structure in both low and high AOA conditions. An airplane’s aerodynamic balance and controllability are governed by changes in the CP.

|

| Figure 3. Pressure distribution on an airfoil and CP changes with AOA |

Airfoil Behavior

Although specific examples can be cited in which each of the principles predict and contribute to the formation of lift, lift is a complex subject. The production of lift is much more complex than a simple differential pressure between upper and lower airfoil surfaces. In fact, many lifting airfoils do not have an upper surface longer than the bottom, as in the case of symmetrical airfoils. These are seen in high-speed aircraft having symmetrical wings, or on symmetrical rotor blades for many helicopters whose upper and lower surfaces lift is a complex subject. The production of lift is much more complex than a simple differential pressure between upper and lower airfoil surfaces. In fact, many lifting airfoils do not have an upper surface longer than the bottom, as in the case of symmetrical airfoils. These are seen in high-speed aircraft having symmetrical wings, or on symmetrical rotor blades for many helicopters whose upper and lower surfaces are identical. In both examples, the only difference is the relationship of the airfoil with the oncoming airstream (angle). A paper airplane, which is simply a flat plate, has a bottom and top exactly the same shape and length. Yet, these airfoils do produce lift, and “flow turning” is partly (or fully) responsible for creating lift.

As an airfoil moves through air, the airfoil is inclined against the airflow, producing a different flow caused by the airfoil’s relationship to the oncoming air. Think of a hand being placed outside the car window at a high speed. If the hand is inclined in one direction or another, the hand will move upward or downward. This is caused by deflection, which in turn causes the air to turn about the object within the air stream. As a result of this change, the velocity about the object changes in both magnitude and direction, in turn resulting in a measurable velocity force and direction.

A Third Dimension

To this point, the discussion has centered on the flow across the upper and lower surfaces of an airfoil. While most of the lift is produced by these two dimensions, a third dimension, the tip of the airfoil also has an aerodynamic effect. The high-pressure area on the bottom of an airfoil pushes around the tip to the low-pressure area on the top. [Figure 4] This action creates a rotating flow called a tip vortex. The vortex flows behind the airfoil creating a downwash that extends back to the trailing edge of the airfoil. This downwash results in an overall reduction in lift for the affected portion of the airfoil. Manufacturers have developed different methods to counteract this action. Winglets can be added to the tip of an airfoil to reduce this flow. The winglets act as a dam preventing the vortex from forming. Winglets can be on the top or bottom of the airfoil. Another method of countering the flow is to taper the airfoil tip, reducing the pressure differential and smoothing the airflow around the tip.

|

| Figure 4. Tip vortex |